A Utility Perspective on Renewables and Biomass Doug Boylan – Southern Company

advertisement

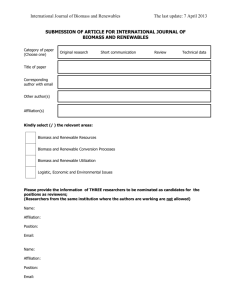

A Utility Perspective on Renewables and Biomass Doug Boylan – Southern Company Traditional Utility • Goals – Low cost, reliable energy provider • Selected technologies – Hydro, nuclear, coal, natural gas Drivers Toward Renewables • Green house gas mitigation • Market demand for Green Power • Government mandated Renewable Portfolio Standards (RPS) • Seeking lowest cost renewable energy options Seeking Low Cost Large Scale Options for RPS • • • • • • (Southeast US) Solar - $$$ Wind – Good, but limited in resource Landfill gas – Good, but limited resource Small hydro – Good, but limited resource Biomass – Good? Purchase Credits – Sets renewable cost cap Biomass Options Co-firing • Uses existing plant • Displaces coal directly • Reduced capital costs • Application limited by ash and operational considerations • Co-Mill – limited percentage (3-5%) • Direct Injection – Higher percentage (10 - 20%), higher cost Biomass Options Gasification • Higher capital cost • Higher efficiency • Displaces a higher cost fuel • Greater potential to meet large RPS generation needs Contrast Wood and Grass as Fuels Grass Wood Fuel Cost ($/MMBtu) 3–4 2 – 3.5 Moisture 10-15% 20-60% Metals Low Low Sulfur Low Low NOx Moderate N Low N Slagging and Fouling High K Moderate K Catalyst effect High? Moderate? Ash sales ? Non-spec Low Non-spec Co-fire ¢/kWh (Est.) 2.6 – 3.0 0 – 2.6 Gasification ¢/kWh (Est.) ? 1.0 – 3.0 Biomass - Closed and Open Loop • Biomass will probably need tax or other incentives to compete • Tax incentives have tended to favor Closed Loop • Grass probably has the best opportunity to be Closed Loop Conclusions From the Utility perspective: • Biomass has potential to supply RPS requirements • Grasses and wood each have advantages and disadvantages • Utility desire is to keep funds in our service area • Biomass will probably need tax credits or other support to be viable for renewable energy Questions? Costs of Co-Fire 0.040 Sulfur benefit 0.035 NOx benefit milling energy cost Labor cost Cost Differential ($/kwh) 0.030 Capital cost fuel diff cost 0.025 0.020 0.015 0.010 0.005 0.000 grass -0.005 benefits co-mill benefits dir inj benefits