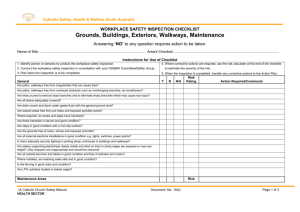

Workplace Inspection Checklist - Safety Audit

advertisement

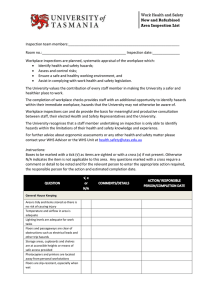

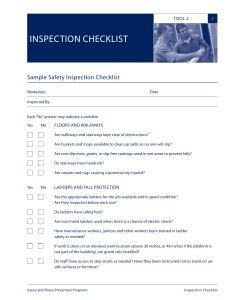

Work Health and Safety General Workplace Inspection Checklist Indicate in the following manner: = Acceptable; = Not Acceptable - Action required; N/A = Not Applicable Organisational Unit: , , Recommended Control (Must complete for all “” items) By Whom Completion Date Review Date N/A Work Area: Date: / / Inspection Team: Any other persons in area involved during the inspection: Review of previous workplace inspection has been completed, including effectiveness of control measures implemented? (Record any issues at the end of this checklist) = Acceptable; = Not Acceptable - Action required; , , N/A = Not Applicable N/A Record findings in the following manner: 1. Housekeeping 1.1 1.2 1.3 1.4 1.5 1.6 1.8 Free from rubbish and obstructions Free from slip/trip hazards Doors and windows functional and accessible Floor coverings Stock/material stored safely and tidy Vision at corners Provision of adequate waste disposal 2. Electrical Recommended Control (Must complete for all “” items) By Whom Yes / Completion Date 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 2.9 2.10 2.11 2.12 2.13 2.14 No broken plugs, sockets, switches No frayed or defective leads (tag and test dates) Power tools in good condition No work near exposed live electrical equipment No strained leads No cable-trip hazards Switches/circuits/circuit breakers identified Switchboards secured and identified Exterior weatherproof fittings in good condition Heaters safely located/in working order Battery chargers marked and well ventilated No temporary or makeshift leads/power boards? No double adaptors or piggy backing Are residual current detectors in use for portable equipment? 2.15 Photocopiers not located close to personal workstations 3. Environmental factors including Lighting, Ventilation, Temperature and Noise 3.1 3.2 3.3 3.4 3.5 3.6 3.7 Adequate in general area (visibility / glare) No flickering or inoperable lights Windows clean Emergency lighting system checked Adequacy of ventilation / airflow Noise levels meet exposure standards Noise level does not interfere with communication/emergency signals Temperature range comfortable 3.8 9. Personal Protective Equipment (PPE) 9.1 9.2 Employees provided with effective PPE PPE being worn appropriately by employees, and in good condition PPE supply / storage facilities located where needed 9.3 No Review Date Work Health and Safety General Workplace Inspection Checklist Indicate in the following manner: = Acceptable; = Not Acceptable - Action required; N/A = Not Applicable 10. Manual Handling / Ergonomics 10.1 10.2 Mechanical aids adequate for current needs Safe work procedures (SWP) communicated and being followed Transfer Procedure Charts up to date Manual handling risk assessments performed Manual handling controls implemented No unnecessary/excessive bending/stooping? Work surfaces [desks, benches] are set up at the appropriate height? Work is oriented for easy access to pedals, grips, phones, computers? Routine tasks do not require individuals to lift excessive weight (mechanical equipment available for lifting heavy loads) Adjustable seating is available when needed? Footrests are available for those who need? Frequently used items and/or heavy loads are stored at easily accessible / safe heights Adequate rest breaks taken during repetitive tasks or tasks involving sustained postures 10.3 10.4 10.5 10.6 10.7 10.8 10.9 10.10 10.11 10.12 10.13 4. Lifting Equipment 4.1 4.2 4.3 4.4 4.5 Mechanical lifting equipment in good condition Manual lifting equipment in good condition Hazard reporting/maintenance system used Satisfactory operating practices noted Wheels satisfactory , , N/A 7. Stairs, Steps and Landings 7.1 7.2 7.3 7.4 7.5 7.6 7.7 7.8 7.9 No worn or broken steps Handrails in good repair Clear of obstructions and slip/trip hazards, including debris and spills Adequate lighting Emergency lighting Non-slip treatments/treads in good condition Kick plates where required Used correctly Floors have even surfaces [no cracks etc]? 8. Ladders 8.1 8.2 8.3 8.4 Ladders in good condition and registered Not used to support planks for work platforms Correct angle to structure 1:4 Ladders extend 1 metre above highest landing 8.5 Straight or extension ladders securely fixed at top 13. First Aid Treatment and Equipment 13.1 Record of treatment and of supplies dispensed up to date Incident reports filled out correctly First aid kits are accessible, prominently displayed, and clean/orderly. Are staff aware of nominated first aiders? Safety showers / eye wash facilities available if required, and functional and accessible? Self Contained Breathing Apparatus has been recertified within the last 12 months? 13.2 13.3 13.4 13.5 13.6 Recommended Control (Must complete for all “” items) By Whom Completion Date Review Date Work Health and Safety General Workplace Inspection Checklist Indicate in the following manner: = Acceptable; = Not Acceptable - Action required; N/A = Not Applicable 14. Emergency Procedures 14.1 14.2 14.3 14.4 14.5 Procedures easily accessible Emergency plan/procedures displayed Evacuation drill within last 12 months Emergency personnel identified and trained Emergency telephone numbers clearly displayed, including emergency numbers posted on each phone 15. Fire Control 15.1 Extinguishers and fire blankets supplied and appropriate for work area where required Fire fighting equipment serviced/tagged Appropriate signing of extinguishers Fire equipment accessible Smoking/naked flame restrictions observed Minimum flammable quantities at workstation Overhead sprinkler/detectors clear of obstructions, stores, etc? 15.2 15.3 15.4 15.5 15.6 15.9 16. Security 16.1 16.2 16.3 Premises secure during minimum staff shifts Adequate lighting to/from car parking area Security procedures effective 17. Public Protection 17.1 17.2 17.3 17.4 17.5 Appropriate site access control, barricades, fencing, hoarding, gantry secure and in place Signage in place (including traffic control) Suitable lighting for public areas Footpaths clean and free from debris Public health and safety complaints actioned 18. Means of Egress 18.1 Exit doors marked, clearly visible and accessible Exit doors can be opened from inside [no padlocks] Exit corridors, ladders, catwalks, etc are clear of obstructions? 18.2 18.3 19. Hazardous Substances 6.1 6.2 6.3 6.4 6.5 6.6 6.7 6.8 6.9 6.10 6.11 Stored appropriately All substance containers labelled adequately Adequate ventilation Protective clothing/equipment available/used Personal hygiene – dermatitis control Waste disposal procedures followed Safety data sheets available/displayed Chemical handling procedures followed Drip trays used where appropriate Chemical register up to date (Chemwatch) Correct gas cylinder storage 20. Signs / Information 23.1 23.2 Safety signs adequate and used appropriately Is special signage for radiation, biological or other hazards prominently posted? Are relevant hazard posters effectively posted at entrances and in work areas? 23.3 , , N/A Recommended Control (Must complete for all “” items) By Whom Completion Date Review Date Work Health and Safety General Workplace Inspection Checklist Indicate in the following manner: = Acceptable; = Not Acceptable - Action required; N/A = Not Applicable , , Recommended Control (Must complete for all “” items) By Whom Completion Date N/A Specific work environments that will not be applicable to all work areas being inspected: 11. Kitchen Areas (Eating/Drinking) 11.1 11.2 11.3 11.4 11.5 11.6 11.7 Equipment in good working order Trolleys in good working order Hot/Heavy items handled safely Clean and hygienic Refrigeration door operable from inside Refrigeration alarm operable from inside Floors not slippery 12. Storage Areas 12.1 12.2 12.3 12.4 12.5 12.6 12.7 12.8 12.9 12.10 Stacks / Shelves / Racks stable Heights correct Sufficient space for moving stock Shelves free of rubbish Floors around stacks and racks clear Heavier items stored at convenient level No danger of falling objects No sharp edges Safe means of accessing high shelves Racks clear of lights/sprinklers 19. Biological Safety - General 19.1 Are safe work procedures in place for lab techniques (including minimisation of aerosols)? Are cleaning procedures established for normal cleaning and emergency spills? Are autoclaves/procedures available for disinfection? Are staff aware of decontamination procedures established? Are sharps and biohazardous waste procedures established and implemented? Is all research approved (where required) by the appropriate agency/ethics committee? Is specialised PPE available for use by staff/students? Have all staff/students been provided with information on appropriate vaccinations? 19.2 19.3 19.4 19.5 19.6 19.7 19.8 20. Animal Facilities 20.1 Separate facilities are provided for animal storage, cleaning exam, etc. Infected and non-infected animals are segregated All staff are trained on safety procedures associated with animal handling? 20.2 20.3 5. Maintenance Workshop 5.1 5.2 5.3 5.4 5.5 Adequate work space Clean and tidy Free from excess oil and grease Machines adequately guarded Tool inventory correct and tools in proper place Review Date Work Health and Safety General Workplace Inspection Checklist Indicate in the following manner: = Acceptable; = Not Acceptable - Action required; N/A = Not Applicable 21. Machine/Workshop Basic Safety 21.1 21.2 21.3 21.4 21.5 25 25.1 25.2 25.3 25.4 25.5 Are machines built in accordance with relevant Australian Standards? Are safe operating instructions/warning signs clearly visible? Are machines guarded / protected to prevent contact, entanglement or damage? Have preventative maintenance arrangements been made if required? Are machines appropriate for the area of use (ie explosion proof, etc)? Fume Cupboards Are electrical services located outside the chamber? Are emergency switches clearly identified for power and gas supply? Has the cupboard been inspected and certified within the last 12 months? Are restrictions posted near fume cupboards (< 2.5 L of flammables, no H3C1O4, etc?) Are fume cupboards appropriate for type of hazard (ie radiation, biological, etc)? 26. Laminar Flow Cabinets 26.1 Have all laminar flow cabinets been certified within the last 12 months? Are procedures for appropriate use of cabinets posted? Do the cabinets look clean and tidy (ie, routine cleaning performed recently)? 26.2 26.3 27. Health and Wellbeing 27.1 27.2 27.3 Are showers available? Gymnasium accessible? Toilets accessible COMMENTS / ADDITIONS , , N/A Recommended Control (Must complete for all “” items) By Whom Completion Date Review Date Work Health and Safety General Workplace Inspection Checklist Indicate in the following manner: = Acceptable; = Not Acceptable - Action required; N/A = Not Applicable Key Actions: HSR Signature Manager/Supervisor Signature Officer Signature , , N/A Recommended Control (Must complete for all “” items) By Whom Completion Date Review Date