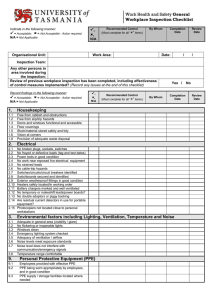

WHS Area Inspection Checklist - University of Tasmania

advertisement

Work Health and Safety New and Refurbised Area Inspection List Inspection team members:_________________________________________________________ Room no.:___________________________________________ Inspection date:______________ Workplace inspections are planned, systematic appraisal of the workplace which: Identify health and safety hazards; Assess and control risks; Ensure a safe and healthy working environment, and Assist in complying with work health and safety legislation. The University values the contribution of every staff member in making the University a safer and healthier place to work. The completion of workplace checks provides staff with an additional opportunity to identify hazards within their immediate workplace, hazards that the University may not otherwise be aware of. Workplace inspections can and do provide the basis for meaningful and productive consultation between staff, their elected Health and Safety Representatives and the University. The University recognises that a staff member undertaking an inspection is only able to identify hazards within the limitations of their health and safety knowledge and experience. For further advice about ergonomic assessments or any other health and safety matter please contact your WHS Advisor or the WHS Unit at health.safety@utas.edu.au Instructions: Boxes to be marked with a tick (√) as items are sighted or with a cross (x) if not present. Otherwise N/A indicates the item is not applicable to this area. Any questions marked with a cross require a comment or detail to be noted and for the relevant person to enter the appropriate action required, the responsible person for the action and estimated completion date. General House Keeping Area is tidy and items stored so there is no risk of causing injury Temperature and airflow in area is adequate Lighting levels are adequate for work tasks Floors and passageways are clear of obstructions such as electrical leads and other trip hazards Storage areas, cupboards and shelves are at accessible heights or means of safe access provided Photocopiers and printers are located away from personal workstations Floors are slip-resistant, especially when wet Work Health and Safety New and Refurbised Area Inspection List Ergonomics Provisions have been made for all activities involving constrained /awkward postures or repetitive/forceful actions to ensure prevention of overuse injuries All workstations are set up correctly and equipped adequately Emergency Response All access and egress areas are clear of obstructions Emergency exit signage is adequate, clearly visible and functioning correctly Emergency lighting levels are sufficient Exit doors can be opened from the inside at all times Fire fighting equipment visible and clear of obstruction Where necessary, all fire doors close fully Emergency evacuation procedure is correct and clearly displayed Fire wardens and other emergency contact numbers clearly identified in all areas First aid kits visible and readily accessible First aid facilities are adequate for the type of work being undertaken First aid personnel and contact numbers identified Electrical Safety All electrical appliances have current test tag, or a ‘New to service’ tag. Switches/circuits/circuit breakers clearly identified Residual current devices (RCDs) supplied and in use for all field or portable electrical equipment Any powerboards have appropriate overload protection Personal Protective Equipment (PPE) Signs displaying the required PPE for the workplace are displayed and in a prominent place All appropriate PPE is provided Is this section relevant? [Yes] [No] (if no, go to next section) Work Health and Safety New and Refurbised Area Inspection List All PPE is stored effectively Hazardous Substances/Chemical Safety Is this section relevant [Yes] [ No ] (if no, go to next section) Fridges and freezers are provided for sample storage only All laboratory fridges are appropriately labelled with ‘Not for food or drinks’ signage and modified to be spark proof if needed Chemical segregation is in place with appropriate storage lockers used as needed for flammables and S8 poisons Area has adequate ventilation for chemicals Flammable liquid cabinets are at least 3m from any potential ignition source Appropriate secondary containment is in place where needed All fume cupboards are in test and operational There are adequate facilities for controlling the release of fumes/vapours/gases/dusts/mists Eyewash stations and emergency showers are accessible, working and adequately identified Safety data sheets (SDSs) and any other safety information is available for all chemicals A register of all hazardous chemicals for the area is available and kept up to date All chemical waste containers are clearly marked to avoid contamination of solvents with acids or other oxidising agents All waste containers are available for sharps/glassware/biohazards/toxic substances/radioactive waste, carcinogens Compressed/Liquefied Gas Is this section relevant? [Yes] [No] (if no, go to next section) All gas cylinders are properly restrained with chain or similar to wall or brackets All cylinders are at least 3m from potential ignition sources All reticulated gas lines are labelled Cylinder Storage Area Is this section relevant? [Yes] [No] (if no, go to next section) Work Health and Safety New and Refurbised Area Inspection List Storage area is well ventilated Storage area is protected from heat sources and fire risks All cylinders are stored vertically and are properly secured Cylinders are segregate according to Dangerous Goods class Cryogenic Liquids Is this section relevant? [Yes] Is this section relevant? [Yes] [No] (if no, go to next section) Cryogenic liquids are stored in areas with adequate ventilation (not in cold rooms or confined spaces) Machinery/Plant Safety Safe work method/operation instructions and warning signs clearly visible Machines adequately guarded/protected to prevent contact, entanglement or damage. There is easy access to emergency stop buttons PPE requirements are clearly displayed Workshop floor has clearly outlined safe walkways Request induction and training for all plant and equipment that have been installed in infrastructure of building. Ensure copies of manuals or operating procedures are available. Ensure OU is aware of any equipment they need to enter on own maintenance schedule. Other Comments: [No] (if no, go to next section)