Enrique Garcia Bordeje_mic mes mat 2016_preprints 2.docx

advertisement

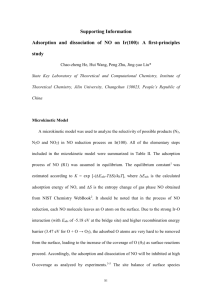

Publised in Microporous and Mesoporous MaterialsVolume 222, 1 March 2016, Pages 5562 Bio-sourced mesoporous carbon doped with heteroatoms (N,S) synthesised using one-step hydrothermal process for water remediation. Laura Roldán, Yanila Marco, Enrique García-Bordejé Instituto de Carboquímica (ICB-CSIC), Miguel Luesma Castán 4, E-50018 Zaragoza, Spain, jegarcia@icb.csic.es Abstract Mesoporous carbon monoliths doped with nitrogen, sulphur or both have been prepared in one step hydrothermal carbonization from bio-based precursors. Glucose and pyrrole carboxaldehyde or glucose and thiophene carboxaldehyde aqueous solutions have been used as precursors for nitrogen and sulphur doped carbon materials, respectively. In the same hydrothermal process, a salt-templating approach was used to endow the material with mesoporosity. Additionally, the materials were also pyrolyzed in N2 at 973 K. The average mesopore size of resulting xerogels is tuned by the used dopant. Both the doping and mesoporosity enhanced substantially the adsorption of large dye molecules. Accordingly, these metal-free, cost-effective and sustainable materials are excellent candidates for liquid phase environmental and energy applications where the dopant may play a role as catalytic active phase or electronic modulator. * Corresponding author: Tel.:+ 34 976733977; fax.: +34 976733318 E-mail address: jegarcia@icb.csic.es 1 Keywords hydrothermal carbon; mesoporosity; heteroatom-doped carbon, nitrogen, sulfur 1. Introduction The rational design of high performance and cheap nanomaterials for multiple sustainable energy and environmental applications is extremely urgent but remains challenging. Carbons doped with heteroatoms (N, S) with tailored chemical composition are required for some applications in which the incorporation of heteroatoms showed some benefits such as metal-free catalysis or electrocatalysis. The doping element affects conductivity, active sites and wettability of the carbon material which is worth to explore. Top-down processes typically used for the synthesis of porous carbons (such as physical or chemical activation) does not allow a well-defined doping with heteroatoms. Hydrothermal carbonization (HTC) of carbohydrates is a bottom-up process that allows the preparation of carbon materials with tailored heteroatom content [1]. Nitrogen doped HTC [2] and Nitrogen and Sulphur co-doped HTC [3,4] were prepared in one step using glucose plus a building block containing the heteroatom. These materials have been used in several applications such as electrocatalyst for oxygen reduction reaction [2-4] or for capacitive deionization [5]. Other important aspect is the development of porosity, especially mesoporosity, which is crucial for the adsorption or catalytic application in liquid phase involving large molecules (high weight compounds, dyes or biomolecules) [6-8]. Sometimes a sacrificial template such silica nanoparticles has been used to create mesoporosity, but this approach requires multiple steps and the use of hazardous reagents [9-16]. It is beneficial if mesoporosity can be generated in one-pot during hydrothermal 2 carbonization. The use of a special precursor (ovoalbumina) led to a mesoporous material [3] but the surface area is not very high (below 300 m2 g-1) even for the pyrolized material. Borax was used to prepare N-doped HTC with mesoporosity[4] and after pyrolysis at 1173 K the maximum surface area was 427 m2 g-1 formed by pores between 4-24 nm. A similar approach is the so-called “salt templating” method using ionic liquids or eutectic salt mixtures as porogen [17]. Using this approach, Fechler et al. prepared aerogel-like mesoporous bodies by using hypersaline conditions [18]. The basic concept behind is that the hypersaline conditions stabilize the surface of the asformed primary small nanoparticles (<50 nm) to avoid Ostwald ripening or excessive particle growth. These primary particles at sufficiently high concentration then turn collectively unstable, undergoing spinodal phase separation and cross-linking toward the final porous carbon gels. The more salt is added, the smaller the primary particles are and hence the higher the surface area is. Thus, this method allows structural control by varying the salt concentration and salt type. Recycling of the reaction medium in all these cases is very simple: the salt is washed away with water, filtered, and can be reused after evaporation of the water. This procedure creates a mesoporous monolithic bodies in one single step. A variant of this approach is when ZnCl2 is not washed after hydrothermal carbonization and the material is pyrolised. During pyrolysis, the remaining ZnCl2 has a second role as an activating agent to develop futher microporosity [19]. Following this later approach, other authors prepared mesoporous carbon materials introducing ZnCl2 during hydrothermal carbonization of coconut shell in a 2:1 weight ratio [20,21]. In that case, the solid was not washed after hydrothermal synthesis but pyrolyzed it at 1073 K. As far as we know, salt templating approach has not been used to generate mesoporosity in heteroatom doped carbons. Herein, we explored how this approach allows tuning the 3 dopant content and mesopore size in one pot. The prepared materials have showed enhanced performance in the adsorption of dyes even without the need of an activation step. It is foreseen that these materials will exhibit enhanced performance in liquid phase reactions of energy and environmental interest. 2. Experimental For the preparations, anhydrous Glucose (panreac), Pyrrole-2-carboxaldehyde (SigmaAldrich), 2-Thiophenecarboxaldehyde (Sigma-Aldrich) were used. For the synthesis of N-doped carbon materials, 3 g of anhydrous Glucose, 4,5 g of ZnCl2, 0,50 g (5.3 mmol) of Pyrrole-2-carboxaldehyde and 1,5 mL of H2O were thoroughly mixed. The mixture was transferred a glass vessel that was introduced in a Teflon-lined autoclave and kept at 463 K under autogenous pressure for 19 h. For the synthesis of S-doped carbon materials, 3 g of anhydrous Glucose, 4,5 g of ZnCl2, 0,59 g (5.3 mmol) of 2-Thiophenecarboxaldehyde and 1,5 mL of H2O were thoroughly mixed and treated in the autoclave in the same conditions mentioned above. For the synthesis of dual N,S-doped carbon materials, 3 g of anhydrous Glucose, 4,5 g of ZnCl2, 0,50 g of Pyrrole-2-carboxaldehyde, 0,59 g of 2-Thiophenecarboxaldehyde and 1,5 mL of H2O were thoroughly mixed and treated in the autoclave as mentioned above. After hydrothermal synthesis, the solid was introduced in 500 ml of water and kept overnight. Subsequently, it was filtered, washed with abundant water and dried at 383 K in an oven. Surface areas were determined by N2 adsorption at 77 K (BET) using a Micromeritics ASAP 2020 apparatus, after outgassing for 4 h at 423 K. From the physisorption measurements with N2, the specific surface area has been calculated by the BET 4 (Brunauer, Emmet, and Teller) theory in the relative pressure range 0.01–0.10 following standard ASTM-4365, which is applicable to microporous materials. Total pore volume (VT) was calculated from the amount of N2 adsorbed at a relative pressure of 0.99. Pore-size distribution was obtained from the desorption branch of the N2 isotherm according to the BJH method (Barrett-Joyner-Halenda) using the DataMaster V4.0 software and assuming slit pore geometry. BJH model developed in 1951 which is based on the Kelvin equation and corrected for multilayer adsorption, is most widely used for calculations of the pore size distribution in the mesoporous and part of the macroporous range [22]. Microporous volume (Vµ) was estimated by Density Functional Theory (DFT method), which is applicable to materials with both micro and mesopores [23]. The model fitted quite well to the isotherm with a standard deviation of ~0.05 cm³ g-1 STP. Alternatively, it was also determined by CO2 adsorption (DubininRadushkevich) at 273 K in the same apparatus, after outgassing under the same conditions. CHS analyses were carried out by combustion in a ThermoFlash 1112 elemental analyzer equipped with a TCD detector. Oxygen analysis was done by direct assay which involves pyrolysis of the sample at 1343 K in a nickel/carbon bed under a known He flow. The outlet flow, after passing through a separation column, ends in a TCD detector. The oxygen content of sample is quantified on the basis of CO analyzed. SEM analysis was carried out with a microscope SEM EDX Hitachi S-3400 N with variable pressure up to 270 Pa and with an analyzer EDX Röntec XFlash of Si(Li). The samples were sputtered with gold previously to measurements. The images were obtained from the secondary electron signal. HRTEM of was carried out using a FEI TECNAI F30 electron microscope equipped with Gatan Energy Filter and cold field emission gun (FEG) operated at 300 kV with 5 1.5 Å lattice resolution. TEM specimens were prepared by ultrasonic dispersion in ethanol and a drop of the suspension was applied to a holey carbon support grid. Ex-situ XPS spectra were recorded with an ESCA+ (Omicron) system equipped with Al/Mg radiation source to excite the sample. Calibration of the instrument was done with Ag 3d5/2 line at 368.27eV. All measurements were performed under UHV, better than 10−10 Torr. Internal referencing of spectrometer energies was made using the dominating C 1s peak of the support at 284.6 eV. The program used to do curve fitting of the spectra was CasaXPS after baseline Shirley method. For the adsorption tests, two dyes with different molecular sizes were employed, namely, methylene blue and Rhodamine B. To this end, 2 mg of the porous xerogels was immersed into 12 mL of a 0.05 mg mL−1 aqueous solution of the dye, which was then gently shaken in an incubator at 20 °C for 72 h to ensure that the adsorption equilibrium is reached. The adsorbed amounts were then calculated from the difference between the initial and equilibrium concentration of the dye, as determined with UV–vis absorption spectroscopy. 3. Results and discussion The hydrothermal carbonisation produced xerogel bodies which adopt the form of the mould in which they are synthetized (Figure S1 supplementary material). The microscopy inspection of the materials (Figure 1) revealed that the prepared materials have similar morphology, irrespective if they are undoped, N-doped or S-doped. They are formed by the aggregation of primary particles of size smaller than 20 nm (Figure 2a,b) and the high magnification shows that they have an onion-like morphology. When the material is pyrolized at 973 K, it is possible to see small nanodomains leaving pores 6 between them (Figure 2 c, d) although the morphology of the particles transforms slightly from rounded to flake-like. b a 4 µm 50 µm d c 4 µm 4 µm Figure 1 7 a b 20 nm 10 nm c d 50 nm 50 nm Figure 2. 8 Table 1. Textural parameters obtained from N2 (77 K) sample BET Area SN2 Total pore Micropore volume (VT) volume a (Vµ) Mesopore Percentage Average volume mesopores pore (Vm) (Vm/VT*100) diameter (Dp) m2 g-1 cc g-1 cc g-1 cc g-1 % nm 7 0.014 0.002 0.012 - <2 HTC-973 541 0.22 0.18 0.04 18 <2 HTC-Zn 373 0.26 0.12 0.14 53 3.5 HTC-Zn-973 520 0.27 0.20 0.07 26 3.5 HTC-N-Zn 503 0.60 0.15 0.44 73 12.0 HTC-N-Zn-973 450 0.48 0.14 0.33 68 8.2 HTC-N-Zn- 1510 0.77 0.54 0.22 28 34 HTC-S-Zn 288 0.56 0.06 0.50 89 32 HTC-S-Zn-973 559 0.66 0.15 0.50 75 2 HTC-N-S-Zn 174 0.27 0.04 0.23 85 32 HTC-N-S-Zn-973 477 0.37 0.14 0.23 62 33 HTC unwashed-973 a obtained by DFT model applied to N2 adsorption isotherm 9 Table 2. Textural parameters obtained from CO2 physisorption (273 K) for selected samples. Surface area ultramicropore volume (SCO2) (VCO2) m2g−1 cm3g−1 HTC 142 0.06 HTC-973 608 0.24 HTC-Zn 252 0.1 HTC-Zn-973 511 0.22 sample Table 1 compiles the textural parameters of different samples. HTC sample, which was prepared without salt templating, showed negligible surface area measured by N2 physisorption (Figure 3). For HTC calcined at 973 K (HTC-973), the surface area is not negligible and the isotherm is of type I indicative of microporous material. Thus, the pyrolysis of HTC develops microporosity accessible to N2. To get further insight about microporosity, HTC and other selected samples were also characterized by CO2 adsorption (Figure 4 and Table 2) showing a non-negligible surface area of 142 m2g-1. In samples HTC and HTC-973, SCO2>SN2 and VCO2>VT, indicating the presence of ultramicorporosity. This is due to kinetic restrictions to N2 diffusion in micropores of dimensions similar to those of the adsorbate [24,25]. The Pore size distribution estimated by application of DFT method to CO2 adsorption isotherm determine a mean pore size of 0.55 nm. On the other hand, in HTC-Zn and HTC-Zn-973, SCO2<SN2 and VCO2<VT because they are predominantly mesoporous as explained next. Figure 5, 6, 7 and 8 display the N2 adsorption isotherms and pore size distribution for salt-templated undoped, N-doped, S-doped and dual (N,S) doped HTC materials, 10 respectively. Unlike to HTC, the adsorption isotherms are of Type IV according to IUPAC with hysteresis loops, indicative of mesoporous materials. The hysteresis loop is not completed for the as-synthesised hydrothermal carbons but it is closed for the pyrolized carbons. This indicates that pyrolized samples have a “permanent porosity” similar to that of conventional activated carbons while as-synthesised carbons have a “non-permanent” porosity which suffers some irreversible swelling upon gas adsorption. The mesoporosity accounts for 50%, 73%, 89% and 85% of total pore volume and the average pore sizes are 3.5 nm, 12 nm, 34 and 32 nm for un-doped, Ndoped, S-doped, dual N,S-doped salt-templated samples, respectively (Table 1 and Figures 5,6,7 and 8). Thus, the dopant molecule tunes the average mesopore size. The pores are widely distributed for doped samples, between 5-30 nm for N-doped and between 10-100 for S-doped and N,S-doped samples. Upon pyrolizing at 973 K, the microporosity increases for all the samples, except for N-doped samples. The increase of microporosity may be rationalized by the release of H2O and COx gases as temperature rises, leaving pores behind. What is more important is that mesopore volume remains after pyrolysis and it is only reduced 46%, 25%, 0% and 0% after pyrolysis of un-doped, N-doped, S-doped, dual N,S-doped samples, respectively. As a standard procedure, ZnCl2 was thoroughly washed with water after hydrothermal synthesis. Only one sample was pyrolized without washing and the remaining ZnCl2 acted as a chemical activating agent leading to the sample named as HTC-N-Znunwashed-973. Its textural properties were very different from washed samples, exhibiting a very high surface (1500 m2g) but with 70% of total pore volume in the microporous range (dotted line in Figure 4). Accordingly, the pyrolysis without washing the Zn leads to a reconstruction of the structure, destroying mesoporosity and creating micropores by activation. 11 Adsorbed volume (cm3g-1 STP) 160 140 120 100 80 60 40 20 0 0 0.2 0.4 0.6 0.8 1 Relative Pressure (P/Po) Figure 3 Adsorbed volume (cm3g-1 STP) 80 70 60 50 40 30 20 10 0 0 0.01 0.02 Relative Pressure (P/Po) Figure 4 12 0.03 Figure 5. Figure 6. 13 Figure 7 Figure 8 In summary, a set of samples with tuneable textural properties have been prepared using a salt templating approach and different heteroatoms dopants, ranging from predominantly microporous to mesoporous with different pore sizes. The surface 14 chemistry of the samples is also different and the results of chemical characterization are shown next. The main results of chemical characterisation by elemental analysis (e.a) and XPS are compiled in Table 3. The materials prepared by one-step hydrothermal carbonisation incorporated the heteroatoms that are initially present in the precursors. In HTC-N-Zn, the nitrogen content is 5.7 wt% and 4.21 wt% determined by elemental analysis and XPS, respectively. The similar values determined by both techniques suggest that the N is distributed quite uniformly throughout the xerogel. For HTC-S-Zn materials, the amount of sulphur determined by XPS doubles that measured by elemental analysis suggesting that the surface is enriched in sulphur. For dual doped sample (HTC-N,SZn), the amount of N and S incorporated are in the same range as for the single doped materials although slightly lower. After pyrolysis, the O content decreases drastically due to its release as H2O or COx. This decomposition did not affect the mesoporous structure significantly (vide supra). The N/C ratio remains at similar values after pyrolysis indicating that N is not removed. In contrast, S/C ratio decreases about 50% after pyrolysis which may be explained by its release as SO2. The N 1s peak of of N-doped materials (Figure 9a) was deconvoluted in four components denoted as pyridine at 398.3±0.1 eV, pyrrolic at 400 ±0.1 eV and quaternary at 401 ±0.1 eV as described in the literature [26-28] . A transformation of the type of nitrogen occurs after pyrolysis at 973 K. The as-synthetized HTC-N-Zn contains pyrrolic nitrogen in agreement with the used precursor. In the pyrolised sample (HTCN-Zn-973), the pyrrolic nitrogen has been transformed to pyridinic and quaternary, i.e the structure has changed from 5-membered to 6-membered ring. This confirms the graphitization of the material when it undergoes the thermal treatment in N2 at 973 K, in 15 agreement with XRD measurements of HTC materials (Figure S3 supplementary information) and with results of other authors [29]. Table 3. Chemical characterisation by elemental analysis and XPS Elemental analysis Weight ratios wt% C O N S e.a. HTC 66.3 27 0.0 0.0 0.0 HTC-Zn 67.6 27 0.0 0.0 HTC-Zn-973 95.3 3.5 0.16 HTC-N-Zn 69.1 22 HTC-N-Zn-973 88.5 N/C S/C Zn/C wt% wt% at% XPS e.a. XPS 0.0 0.0 0.0 0.00 0.0 0.0 0.0 0.0 0.01 0.0 0.0 0.0 0.0 0.0 0.09 3.9 0.00 5.7 4.2 0.0 0.0 0.02 5.7 4.7 0.00 5.3 4.0 0.0 0.0 0.11 77 17 4.2 0.00 5.5 3.9 0.0 0.0 0.15 HTC-S-Zn 64.8 23 0.08 8.3 0.0 0.0 12.8 25.6 1 HTC-S-Zn-973 88.7 3.3 0.10 6.7 0.0 0.0 7.6 15.0 2.3 HTC-N-S-Zn 63.7 24 2.8 5.7 4.4 4.2 9.0 17.1 4.0 HTC-N-S-Zn-973 84.9 6.3 3.7 3.6 4.3 4.0 4.2 10.3 5.7 HTC-N-Znunwashed-973 The 2p XPS peak of S-doped materials (Figure 9b) shows a doublet peak at 163.7 and 165 eV which is attributed the the C-S-C bonding derived from tiophenic group [30]. 16 There is another peak which intensifies after pyrolysis at 161.7 eV which is ascribable to ZnS sphalerite [30]. As can be observed in last column of table 3, the Zn content determined by XPS is negligible for most of the samples, indicating that the washing step after hydrothermal synthesis is very efficient removing ZnCl2 salt, except for S- N1 containing-samples in whichpyridinic the washing of Zn is not so effective and 1-2 at% of Zn is detected by XPS. The peak at 161.7 eV confirms that Zn remains bound to S, hindering pyrrolic the washing out N2 of Zn with water, and eventually leading to ZnS upon pyrolysis. quaternary N3 Intensity (a.u.) N4 HTC-N-Zn Oxidized pyridinic HTC-Zn-N-973 403 a 400 Binding Energy (eV) 17 398 395 3/2 2p HTC-S-Zn 1/2 2p Intensity (a.u) ZnS HTC-Zn-S-973 168 b 167 166 165 164 163 162 161 160 Binding Energy (eV) Figure 9 The materials prepared with different pore texture and dopants were tested in the adsorption of two dye molecules, namely Methylene blue and Rhodamine B. The dimensions of these molecules are 1.43 nm × 0.61 nm × 0.4 nm and 1.59 nm × 1.18 nm× 0.56 nm for Methylene blue and Rhodamine B, respectively. The latter one is slightly larger than the former. The bars in Figure 10 are the dye adsorption capacity normalized per surface area. The numbers inside the bars are the absolute adsorption values. In general, the adsorption capacity of Methylene blue is larger than that of Rhodamine B, which is may be attributed to the slightly smaller size because both are cationic molecules and the interaction with support should not vary much[31]. The doped materials adsorb significantly larger amounts of dye before pyrolysis than after pyrolysis. This can be explained by the higher oxygenated groups content (Table 3) and lower graphitization degree for the un-pyrolised samples, which render a more hydrophilic surface for the penetration of aqueous phase and for enhancing interactions (electrostatic, H-bond) with the dye. The surface area-normalized adsorption follows the 18 same trend for the two dyes HTC-Zn<HTC-N-Zn<HTC-S-Zn. Apparently, the presence of the dopant is beneficial for the adsorption compared to the undoped sample. It is probable that this trend is not consequence of the dopant itself but of the different average pore sizes which is an indirect effect of the dopant heteroatom. It is worth noting that the sample HTC-N-Zn-unwashed-973 adsorbed comparable dye quantity as HTC-N-Zn despite having three-fold higher surface area. In addition, the adsorption kinetics are faster on HTC-N-Zn (Figure S4 supplementary material). This difference could be attributed either to the higher mesoporosity or richer surface chemistry of HTC-N-Zn. Studies of ionic strength would help to separate the effect of mesoporosity and electrostatic interactions but this is beyond the present research. The enhanced dye adsorption for the mesoporous doped materials demonstrates that they are excellent candidates to be used in liquid phase applications beyond water environmental remediation, such as in the field of metal-free catalysis [32-34], electrocatalysis [3,3537] or capacitive deionization [5,38]. Mesoporosity will favour the penetration of the aqueous phase and the diffusion of voluminous molecules in the pores while doping and rich surface chemistry will enhance the interactions with the reactant molecules. In the case of electrocatalytic oxygen reduction reaction, it has been proposed that the reaction mainly occurs in the mesopores, whereas micropores can be detrimental for the diffusion of O2 and electrolyte [39]. Moreover, the carbon materials are prepared using straightforward method and a bio-based precursors, in contrast to the preparation of other mesoporous carbons which involves multiple steps and hazardous reagents. The next step is testing the doped mesoporous carbon in oxygen reduction reaction as metalfree electrocatalyst to replace noble metal catalysts. 19 0.6 0.5 HTC-S-Zn 92 mg g-1 0.4 HTC-N-Zn 38 mg g-1 51 mg g-1 HTC-S-Zn-973 42 mg g-1 166 mg g-1 HTC-N-Zn-973 107 mg g-1 HTC-973 0 HTC-N-Znunwashed-973 46 mg g-1 38 mg g-1 0.1 HTC-Zn-973 43 mg g-1 88 mg g-1 0.2 105 mg g-1 159 mg g-1 HTC-Zn 106 mg g-1 123 mg g-1 0.3 13 mg g-1 Dye adsorption capacity per Surface Area (mg m-2) HTC-N-S-Zn HTC-N-S-Zn-973 Figure 10 4. Conclusions Mesoporous carbon materials doped with nitrogen, sulfur or dual doped have been prepared via hydrothermal carbonisation of glucose and building blocks containing the heteroatom. In the same single step, mesoporosity has been developed in the materials by introducing ZnCl2 as easily removable template. The average mesopore size varies with the type of doping, providing materials with average mesopore sizes of 3.5 nm, 12 nm, 34 and 32 nm for un-doped, N-doped, S-doped, and dual N,S-doped samples, respectively. After thermal treatment at 973 K in N2 gas, the 5-membered rings transforms into 6-membered rings due to an increased graphitization but mesoporosity and N, S content are preserved. The as-prepared hydrothermal carbon has demonstrated substantially higher surface area-normalized adsorption capacity of bulky dye molecules than pyrolised materials and carbon with even three-time higher surface area but mainly 20 microporous. These findings emphasizes that this material can be an excellent candidate for other applications such as electrocatalyst or catalyst in energy and environmental related applications due to the enhanced diffusion of large molecules in aqueous environment. The sustainable and simple nature of the preparation technique guarantees economic and environmental feasibility, a property which graphene and CNT based materials are lacking yet. Moreover, the bottom-up doping approach allows a high level of control over the dopant, which is an elusive goal for graphitic carbon materials that are usually doped following a top-down approach. 5. Aknowledgements. The financial support of European Commission (FREECATS project, FP7 Grant agreement nº 280658) from Spanish Ministry MINECO and the European Regional Development Fund (project ENE2013-48816-C5-5-R), and Regional Government of Aragon (DGA-ESF-T66 Grupo Consolidado) are gratefully acknowledged. References [1] M. M. Titirici, M. Antonietti, Chem.Soc.Rev., 39 (2010) 103-116. [2] N. Brun, S. A. Wohlgemuth, P. Osiceanu, M. M. Titirici, Green Chem., 15 (2013) 2514-2524. [3] S. A. Wohlgemuth, R. J. White, M. G. Willinger, M. M. Titirici, M. Antonietti, Green Chem., 14 (2012) 1515-1523. [4] S. A. Wohlgemuth, T. P. Fellinger, P. Jaker, M. Antonietti, J.Mater.Chem.A, 1 (2013) 4002-4009. [5] S. Porada, F. Schipper, M. Aslan, M. Antonietti, V. Presser, T. P. Fellinger, ChemSusChem, (2015) n/a. 21 [6] K. M. de Lathouder, J. Bakker, M. T. Kreutzer, F. Kapteijn, J. A. Moulijn, S. A. Wallin, Chem.Eng.Sci., 59 (2004) 5027-5033. [7] M. Sevilla, P. Valle-Vigón, P. Tartaj, A. B. Fuertes, Carbon, 47 (2009) 25192527. [8] S. van Donk, A. H. Janssen, J. H. Bitter, K. P. de Jong, Catal.Rev., 45 (2003) 297-319. [9] N. Brun, K. Sakaushi, L. Yu, L. Giebeler, J. Eckert, M. M. Titirici, Phys.Chem.Chem.Phys., 15 (2013) 6080-6087. [10] S. Ikeda, K. Tachi, Y. H. Ng, Y. Ikoma, T. Sakata, H. Mori, T. Harada, M. Matsumura, Chem.Mater., 19 (2007) 4335-4340. [11] J. B. Joo, Y. J. Kim, W. Kim, P. Kim, J. Yi, Catal.Comm., 10 (2008) 267-271. [12] S. Kubo, I. Tan, R. J. White, M. Antonietti, M. M. Titirici, Chem.Mater., 22 (2010) 6590-6597. [13] M. M. Titirici, A. Thomas, M. Antonietti, Adv.Funct.Mater., 17 (2007) 10101018. [14] M. M. Titirici, A. Thomas, M. Antonietti, J.Mater.Chem., 17 (2007) 3412-3418. [15] L. Yu, N. Brun, K. Sakaushi, J. +. Eckert, M. M. Titirici, Carbon, 61 (2013) 245-253. [16] R. mir-Cakan, P. Makowski, M. Antonietti, F. Goettmann, M. M. Titirici, Catalysis Today, 150 (2010) 115-118. [17] N. Fechler, T. P. Fellinger, M. Antonietti, Adv.Mater., 25 (2013) 75-79. [18] N. Fechler, S. A. Wohlgemuth, P. Jaker, M. Antonietti, J.Mater.Chem.A, 1 (2013) 9418-9421. [19] F. Cesano, M. M. Rahman, S. Bertarione, J. G. Vitillo, D. Scarano, A. Zecchina, Carbon, 50 (2012) 2047-2051. [20] A. Jain, V. Aravindan, S. Jayaraman, P. S. Kumar, R. Balasubramanian, S. Ramakrishna, S. Madhavi, M. P. Srinivasan, Sci.Rep., 3 (2013) . [21] A. Jain, S. Jayaraman, R. Balasubramanian, M. P. Srinivasan, J.Mater.Chem.A, 2 (2014) 520-528. [22] E. P. Barrett, L. G. Joyner, P. P. Halenda, J.Am.Chem.Soc., 73 (1951) 373-380. [23] R. Evans, P. Tarazona, Physical review letters, 52 (1984) 557-560. [24] D. Lozano-Castelló, D. Cazorla-Amorós, A. Linares-Solano, Carbon, 42 (2004) 1233-1242. [25] H. Marsh, W. F. K. Wynne-Jones, Carbon, 1 (1964) 269-279. 22 [26] I. Florea, O. Ersen, R. Arenal, D. Ihiawakrim, C. Messaoudi, K. Chizari, I. Janowska, C. Pham-Huu, J.Amer.Chem.Soc., 134 (2012) 9672-9680. [27] T. C. Nagaiah, A. Bordoloi, M. D. Sánchez, M. Muhler, W. Schuhmann, ChemSusChem, 5 (2012) 637-641. [28] J. R. Pels, F. Kapteijn, J. A. Moulijn, Q. Zhu, K. M. Thomas, Carbon, 33 (1995) 1641-1653. [29] L. Yu, C. Falco, J. Weber, R. J. White, J. Y. Howe, M. M. Titirici, Langmuir, 28 (2012) 12373-12383. [30] R. S. Smart, W. M. Skinner, A. R. Gerson, Surf.Interf.Anal., 28 (1999) 101-105. [31] C. C. Wang, J. R. Li, X. L. Lv, Y. Q. Zhang, G. Guo, Energy Environ.Sci., 7 (2014) 2831-2867. [32] Y. Gao, G. Hu, J. Zhong, Z. Shi, Y. Zhu, D. S. Su, J. Wang, X. Bao, D. Ma, Angew.Chem.Int.Ed., 52 (2013) 2109-2113. [33] S. Indrawirawan, H. Sun, X. Duan, S. Wang, J.Mater.Chem.A, 3 (2015) 34323440. [34] H. Watanabe, S. Asano, S. i. Fujita, H. Yoshida, M. Arai, ACS Catal., 5 (2015) 2886-2894. [35] R. Liu, D. Wu, X. Feng, K. Müllen, Angew.Chem.Int.Ed., 49 (2010) 2565-2569. [36] M. Sevilla, L. Yu, T. P. Fellinger, A. B. Fuertes, M. M. Titirici, RSC Adv., 3 (2013) 9904-9910. [37] X. Sheng, N. Daems, B. Geboes, M. Kurttepeli, S. Bals, T. Breugelmans, A. Hubin, I. F. J. Vankelecom, P. P. Pescarmona, Appl.Catal.B: Environ., 176177 (2015) 212-224. [38] L. Liu, L. Liao, Q. Meng, B. Cao, Carbon, 90 (2015) 75-84. [39] X. Wang, J. S. Lee, Q. Zhu, J. Liu, Y. Wang, S. Dai, Chem.Mater., 22 (2010) 2178-2180. Captions to figures Figure 1. Representative SEM images of the hydrothermal carbon aerogels: (a) particle of crushed HTC-Zn xerogel body; (b) HTC-Zn; (c) HTC-N-Zn; (d)HTC-S-Zn 23 Figure 2. Representative TEM image of HTC-N-Zn (a, b), HTC-N-Zn-973 (c) and HTC-S-Zn-973 (d). Figure 3. N2 adsorption isotherms and pores size distribution estimated using the BJH method (inset) for HTC (solid line) and HTC-973 (dashed line). Figure 4. CO2 adsorption isotherms and pores size distribution estimated using the density functional theory method (inset) for HTC (solid line) and HTC-973 (dashed line). Figure 5. N2 adsorption isotherms (a) and pores size distribution estimated using the BJH method (b) for HTC-Zn (solid line) and HTC-Zn-973 (dashed line). Figure 6. N2 adsorption isotherms and pores size distribution estimated using the BJH method for HTC-N-Zn (solid line), HTC-N-Zn-973 (dashed line) and HTC-N-Znunwashed-973 (dotted line). Figure 7. N2 adsorption isotherms and pores size distribution estimated using the BJH method for HTC-S-Zn (solid line) and HTC-S-Zn-973 (dashed line). Figure 8. N2 adsorption isotherms and pores size distribution estimated using the BJH method for HTC-N,S-Zn (solid line) and HTC-N,S-Zn-973 (dashed line). Figure 9. N 1s (a) and S 2p (b) XPS peaks of HTC-N-Zn and HTC-S-Zn, respectively, before and after pyrolysis 24 Figure 10. Surface area normalized adsorption capacity of dyes at equilibrium: methylene blue (grey bars), Rhodamine B (white bars). The absolute absorption values are inside the bars 25