A chemostat...Quiros et al., León 2010.ppt

advertisement

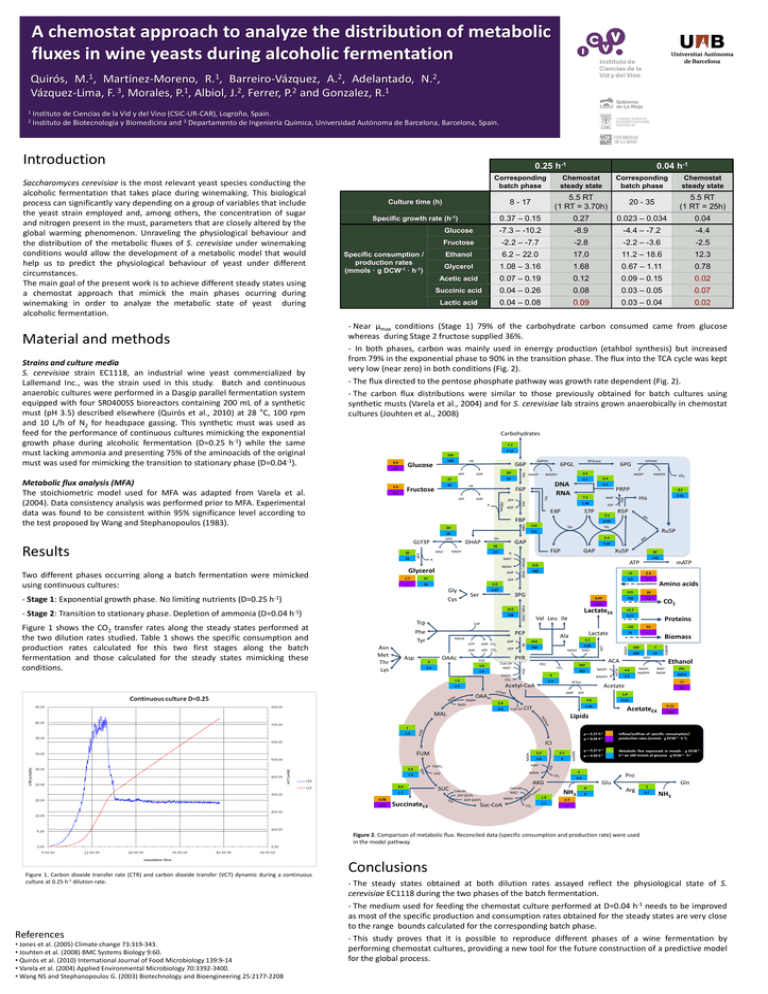

A chemostat approach to analyze the distribution of metabolic fluxes in wine yeasts during alcoholic fermentation Quirós, M.1, Martínez-Moreno, R.1, Barreiro-Vázquez, A.2, Adelantado, N.2, Vázquez-Lima, F. 3, Morales, P.1, Albiol, J.2, Ferrer, P.2 and Gonzalez, R.1 1 Instituto de Ciencias de la Vid y del Vino (CSIC-UR-CAR), Logroño, Spain. 2 Instituto de Biotecnología y Biomedicina and 3 Departamento de Ingeniería Química, Universidad Autónoma de Barcelona, Barcelona, Spain. Introduction Saccharomyces cerevisiae is the most relevant yeast species conducting the alcoholic fermentation that takes place during winemaking. This biological process can significantly vary depending on a group of variables that include the yeast strain employed and, among others, the concentration of sugar and nitrogen present in the must, parameters that are closely altered by the global warming phenomenon. Unraveling the physiological behaviour and the distribution of the metabolic fluxes of S. cerevisiae under winemaking conditions would allow the development of a metabolic model that would help us to predict the physiological behaviour of yeast under different circumstances. The main goal of the present work is to achieve different steady states using a chemostat approach that mimick the main phases ocurring during winemaking in order to analyze the metabolic state of yeast during alcoholic fermentation. Material and methods Strains and culture media S. cerevisiae strain EC1118, an industrial wine yeast commercialized by Lallemand Inc., was the strain used in this study. Batch and continuous anaerobic cultures were performed in a Dasgip parallel fermentation system equipped with four SR0400SS bioreactors containing 200 mL of a synthetic must (pH 3.5) described elsewhere (Quirós et al., 2010) at 28 °C, 100 rpm and 10 L/h of N2 for headspace gassing. This synthetic must was used as feed for the performance of continuous cultures mimicking the exponential growth phase during alcoholic fermentation (D=0.25 h-1) while the same must lacking ammonia and presenting 75% of the aminoacids of the original must was used for mimicking the transition to stationary phase (D=0.04-1). 0.25 h-1 0.04 h-1 Corresponding batch phase Chemostat steady state Corresponding batch phase Chemostat steady state Culture time (h) 8 - 17 5.5 RT (1 RT = 3.70h) 20 - 35 5.5 RT (1 RT = 25h) Specific growth rate (h-1) 0.37 – 0.15 0.27 0.023 – 0.034 0.04 Glucose -7.3 – -10.2 -8.9 -4.4 – -7.2 -4.4 Fructose -2.2 – -7.7 -2.8 -2.2 – -3.6 -2.5 Ethanol 6.2 – 22.0 17.0 11.2 – 18.6 12.3 Glycerol 1.08 – 3.16 1.68 0.67 – 1.11 0.78 Acetic acid 0.07 – 0.19 0.12 0.09 – 0.15 0.02 Succinic acid 0.04 – 0.26 0.08 0.03 – 0.05 0.07 Lactic acid 0.04 – 0.08 0.09 0.03 – 0.04 0.02 Specific consumption / production rates (mmols · g DCW-1 · h-1) - Near µmax conditions (Stage 1) 79% of the carbohydrate carbon consumed came from glucose whereas during Stage 2 fructose supplied 36%. - In both phases, carbon was mainly used in enerrgy production (etahbol synthesis) but increased from 79% in the exponential phase to 90% in the transition phase. The flux into the TCA cycle was kept very low (near zero) in both conditions (Fig. 2). - The flux directed to the pentose phosphate pathway was growth rate dependent (Fig. 2). - The carbon flux distributions were similar to those previously obtained for batch cultures using synthetic musts (Varela et al., 2004) and for S. cerevisiae lab strains grown anaerobically in chemostat cultures (Jouhten et al., 2008) Metabolic flux analysis (MFA) The stoichiometric model used for MFA was adapted from Varela et al. (2004). Data consistency analysis was performed prior to MFA. Experimental data was found to be consistent within 95% significance level according to the test proposed by Wang and Stephanopoulos (1983). Results Two different phases occurring along a batch fermentation were mimicked using continuous cultures: - Stage 1: Exponential growth phase. No limiting nutrients (D=0.25 h-1) - Stage 2: Transition to stationary phase. Depletion of ammonia (D=0.04 h-1) Figure 1 shows the CO2 transfer rates along the steady states performed at the two dilution rates studied. Table 1 shows the specific consumption and production rates calculated for this two first stages along the batch fermentation and those calculated for the steady states mimicking these conditions. Figure 2. Comparison of metabolic flux. Reconciled data (specific consumption and production rate) were used in the model pathway. Figure 1. Carbon dioxide transfer rate (CTR) and carbon dioxide transfer (VCT) dynamic during a continuous culture at 0.25 h-1 dilution rate. References • Jones et al. (2005) Climate change 73:319-343. • Jouhten et al. (2008) BMC Systems Biology 9:60. • Quirós et al. (2010) International Journal of Food Microbiology 139:9-14 • Varela et al. (2004) Applied Environmental Microbiology 70:3392-3400. • Wang NS and Stephanopoulos G. (2003) Biotechnology and Bioengineering 25:2177-2208 Conclusions - The steady states obtained at both dilution rates assayed reflect the physiological state of S. cerevisiae EC1118 during the two phases of the batch fermentation. - The medium used for feeding the chemostat culture performed at D=0.04 h-1 needs to be improved as most of the specific production and consumption rates obtained for the steady states are very close to the range bounds calculated for the corresponding batch phase. - This study proves that it is possible to reproduce different phases of a wine fermentation by performing chemostat cultures, providing a new tool for the future construction of a predictive model for the global process.