Short syllabus

advertisement

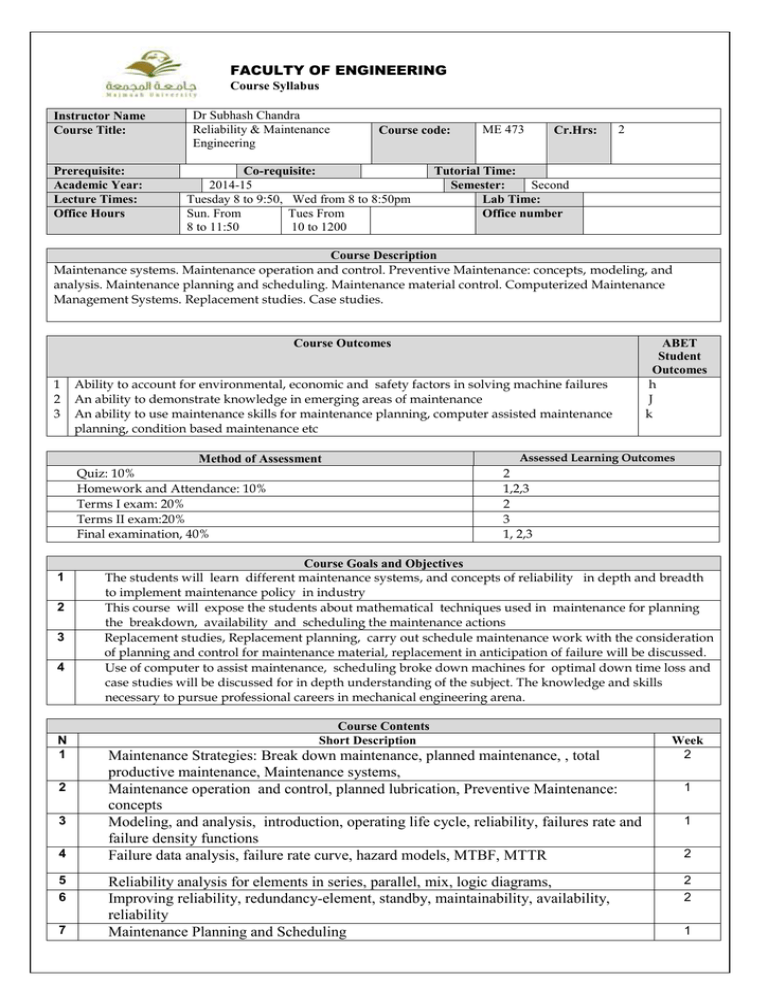

FACULTY OF ENGINEERING Course Syllabus Instructor Name Course Title: Prerequisite: Academic Year: Lecture Times: Office Hours Dr Subhash Chandra Reliability & Maintenance Engineering Course code: Co-requisite: 2014-15 Tuesday 8 to 9:50, Wed from 8 to 8:50pm Sun. From Tues From 8 to 11:50 10 to 1200 ME 473 Cr.Hrs: 2 Tutorial Time: Second Semester: Lab Time: Office number Course Description Maintenance systems. Maintenance operation and control. Preventive Maintenance: concepts, modeling, and analysis. Maintenance planning and scheduling. Maintenance material control. Computerized Maintenance Management Systems. Replacement studies. Case studies. Course Outcomes 1 2 3 Ability to account for environmental, economic and safety factors in solving machine failures An ability to demonstrate knowledge in emerging areas of maintenance An ability to use maintenance skills for maintenance planning, computer assisted maintenance planning, condition based maintenance etc Method of Assessment Quiz: 10% Homework and Attendance: 10% Terms I exam: 20% Terms II exam:20% Final examination, 40% 1 2 3 4 N 1 2 3 4 5 6 7 ABET Student Outcomes h J k Assessed Learning Outcomes 2 1,2,3 2 3 1, 2,3 Course Goals and Objectives The students will learn different maintenance systems, and concepts of reliability in depth and breadth to implement maintenance policy in industry This course will expose the students about mathematical techniques used in maintenance for planning the breakdown, availability and scheduling the maintenance actions Replacement studies, Replacement planning, carry out schedule maintenance work with the consideration of planning and control for maintenance material, replacement in anticipation of failure will be discussed. Use of computer to assist maintenance, scheduling broke down machines for optimal down time loss and case studies will be discussed for in depth understanding of the subject. The knowledge and skills necessary to pursue professional careers in mechanical engineering arena. Course Contents Short Description Maintenance Strategies: Break down maintenance, planned maintenance, , total productive maintenance, Maintenance systems, Maintenance operation and control, planned lubrication, Preventive Maintenance: concepts Modeling, and analysis, introduction, operating life cycle, reliability, failures rate and failure density functions Failure data analysis, failure rate curve, hazard models, MTBF, MTTR Reliability analysis for elements in series, parallel, mix, logic diagrams, Improving reliability, redundancy-element, standby, maintainability, availability, reliability Maintenance Planning and Scheduling Week 2 1 1 2 2 2 1 8 9 10 Maintenance material control, Spare parts management, and inventory control Replacement studies and replacement Analysis Computer assisted maintenance Planning and case study Textbook: 1 2 1 Books T1: Chandra Subhash, Maintenance Engineering and Management, Katson Publication, reprint 2013 R1: Johan P Bentely, An introduction to reliability and quality, Engineering, Longman Scientific and Technical R2Planning & Control of Maintenance Systems, Modeling and Analysis, Duffuaa, S O, Raouf, A & Campbell, J D, John Wiley & Sons, New York, 1999 R3: Terry Wirman World Class Maintenance Management, Industrial press, 1990. R4: Alan Devies, Handbook of condition monitoring, Chapman & Hall R5: Gopal Krishnam P, Maintenance and spare parts management, PHI, New Delhi, 1982.