Project Proposal Slides.

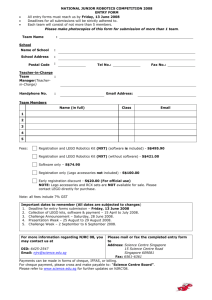

advertisement

Accessible Manufacturing Equipment Phase 2 Proposal Team 2 Nicholas Neumann Ralph Prewett Jonathan Brouker Li Tian Felix Adisaputra Contents Introduction Background Conceptual Design Descriptions Proposed Design Solution Conclusion Introduction Existing Ribbon Cutting Machine PIC Programming C Code Timing Loop Stepper Motors Parallel Operation (Belt) Cam Motors Rotary Cutter Stationary and Movable Clamps Introduction (Continued) Major Problems Programming Interface Complexity Difficult Maintenance Stepper Motors Inaccuracy and Inconsistency Slow Operation Drivers Heat Issues Background Customer Requirements Programming Interface Simplicity Easy Maintenance Motors Precision and Accuracy Variable Speed Control Higher Maximum Speed of Operation Background (Continued) Primary Objectives New Programming Interface Simplicity Future Improvement New Motors Drivers Better Performance Background (Continued) Secondary Objectives Cutter Replacement Noise Reduction Safety Improvement Rollers Replacement Friction Reduction Fan Replacement Reliability Aesthetics Wire Harness FAST Diagram Open Clamps Prevent jam Remove Ribbon Flick Ribbon Cut Precisely Control length Drive Servo Display Length Cut Ribbon Establish Length Basic Function Accept Input Announce Length Control Speed Accept Input Secondary Function Secondary Function Secondary Function Conceptual Design Descriptions LEGO Solution LEGO Mindstorms NXT-G Easier Approach Future Improvement LEGO Servo Motor Compatibility 9V DC Motor Precision and Accuracy Conceptual Design Descriptions (Continued) Conceptual Design Descriptions (Continued) Conceptual Design Descriptions (Continued) Simplified Code Solution C Language Code Simplification Well Commented DC Motor PID Controller Conceptual Design Descriptions (Continued) Hybrid Solution PIC Microcontroller (C Code) Audio Display LEGO NXT Brick (Mindstorm) Movable Clamp Control Future Improvement LEGO DC Servo Motor Compatibility Precision and Accuracy Solution Selection Matrix Importance Engineering Criteria ● ⃝ Δ Safety 4 Aesthetics 2 Revisable Software 5 Noise 2 Δ Δ Compatibility 3 ● Δ Mechanical Maintenance 3 Maturity of Technology 4 Robustness 4 TOTALS ● ⃝ Δ Δ ⃝ ● ● Flipper 5 New Controller Box Accuracy and Precision New Cutter Δ Safety Guards ● Connectors ⃝ C++ Code 5 Δ = 1 (Weak) RobotC Speed of Operation ⃝ = 3 (Moderate) LabVIEW DC Motor LEGO Mindstorms Lego Servo Motor ● = 9 (Strong) Possible Solutions ⃝ ● Δ ● Δ Δ ⃝ ⃝ ⃝ ⃝ ● Δ ⃝ ⃝ ● 101 101 53 39 29 53 ● 21 36 40 6 59 Proposed Design Solution LEGO Solution LEGO NXT Brick Controlling the DC Motor Cutter Mechanism Stationary Clamp Open/Close Function of the Clamp’s Jaws LEGO Servo Motor Transporting Clamp the Movable Proposed Design Solution (Continued) Length Input Current Buttons Interface with LEGO NXT Brick 7-Segment Display Controlled by PIC to Use Fewer NXT I/O Ports Audio Output LEGO NXT Brick Sound System Proposed Design Solution (Continued) Cutter Replacement Rollers Replacement Metal Rollers Fan Replacement Flipper Conclusion Advantages More Customizable Programming Better Accuracy and Precision Compatibility LEGO NXT Brick & LEGO Servo Motors Conclusion (Continued) Disadvantages LEGO NXT Brick Limitation of I/O Ports Lack of Complex Features in the Compiler LEGO Servo Motor Low Overall Torque Conclusion (Continued) Project Management Plan Nicholas Programming Interface Sensors Ralph Programming Motor Interface Drivers Jonathan LEGO Servo Motor Interface Motor Drivers Conclusion (Continued) Li Flipper Implementation Flipper Interface Audio Output Felix Cutter Mechanism Cutter Interface 7-Segment Display Conclusion (Continued) Proposed Budget Quantity Product Description Cost 1 LEGO Mindstorms NXT 2.0* $299.99 2 Bronze Rollers $3.02 1 New Cutter $30.00 1 Flipper $5.00 Miscellaneous $10.00 TOTAL $348.01 *Note: LEGO Mindstorms NXT 2.0 is already provided by our sponsor. References LEGO Mindstorms NXT 2.0 http://shop.lego.com/Product/?p=8547 Extreme NXT: Extending the LEGO Mindstorms NXT to the Next Level