2302 Machine Drafting Syllabus - Spring 2012.doc

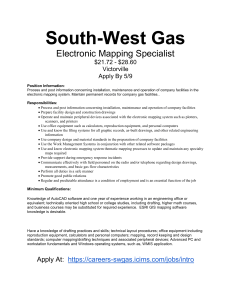

advertisement

1 DFTG-2302 – Machine Drafting Department of Drafting & Design Engineering Technology Houston Community College Syllabus DFTG-2302 Machine Drafting Semester Credit Hours (SCH): 3 Continuing Education Units (CEU): 9.6 Weekly class meeting: 4 hrs Tuesday:5:30 to 9:30 PM Format: Lecture: 1/3 Lab: 1/3 BlackBoard: 1/3 Any question or concern, please contact your instructor first. You can also contact department administration for further assistance. Professor/Instructor: Ken Nguyen Phone number: 832-419-1326 Email: kenqn1998@sbcglobal.net Department Chair: Homied Asgary Phones: 713-718-5731 – Assistant: 713-718-7264 Email: homied.asgary@hccs.edu Mail Code: 1379 Northwest College Spring 2012 Semester: Class (CRN) # 83992 Location (campus/room #): Spring Branch, Room: 314 Office: 1050 W Sam Houston Pkwy North, Suite 200 (next to the Commons) Houston, Texas 77043 PREREQUISITE: DFTG 1305, DFTG-1333 COURSE DESCRIPTION: Production of detail and assembly drawings of machines, threads, gears, cams, tolerances and limit dimensioning, surface finishes, and precision drawings. TEXTBOOK: “Technical Drawing” by Frederick E. Giesecke, [required] published by Prentice Hall, Perason Education Inc. Check with your instructor for the latest Edition MATERIALS: USB Thump Drive. COURSE OBJECTIVES: Interpretation of terms used in tolerancing; determine dimensions of two mating parts; draw spur and bevel gears; and draw set of detail and assembly drawings; define terms used in tolerancing; determine interference and clearances; specify types of threads forms; interpret thread notes; draw spur, bevel, cam profile; and draw a set of detail and assembly drawings. 1. KNOWLEDGE: a. understand the requirements of detailed assembly drawings b. understand the purposes and application of tolerances and tolerance dimensioning c. understand mechanical components and manufacturing processes 2. SKILLS: a. applying tolerance dimensions according to accepted drafting standards b. produce detailed drawing sets for complex machine parts c. calculate tolerances from Appendix data d. convert a cast part into a welded part and apply welding symbols to the part drawing e. research and acquire information from vendor catalogs f. create an assembly drawing and a BOM (Bill of Materials) g. create detailed cam and gear drawings with tolerance notations. 3. ATTITUDES/BEHAVIORS: a. must follow instructions as presented in the classroom b. must participate as a team member in a machine design process c. the student must exhibit patience. SCANS SKILLS: The Department of Labor has identified skill sets that U.S. employers want most in entry level employees. It is our commitment to prepare every student with the knowledge and skills needed to succeed in today’s dynamic environment. Toward this end the following skills will be included in this course: Manage money: uses or prepares budgets, makes forecasts, keeps detailed records to track budget performance, and makes appropriate adjustments. Manage space: acquires, stores, allocates and uses materials or space efficiently. Work on teams: works cooperatively with others and contributes to group with ideas, suggestions, and effort. Reading: Locates, understands, and interprets written information in prose and documents including manuals, graphs, and schedules to perform tasks. Sociability: demonstrates understanding, friendliness, adaptability, empathy and politeness in new and ongoing settings. Students will be presented with a problem in which they will be required to use specifications to develop a work plan. All team members will be responsible for generating ideas, making suggestions as a part of developing the work plan. The plan must include specific recommendations for acquisition, systematically storing, and allocating materials. Preparation of the work plan will require locating and interpreting written information from documents and manuals as well as demonstrating adaptability, understanding and politeness in accepting changes recommended by others in the class during their presentation. Evaluation of these skills will be based on the success of each team’s presentation of their work plan to the class. GENERAL COURSE EVALUATION PROCEDURE: The student will be evaluated and receive a final grade based upon the following criteria: Laboratory work consisting of assigned technical drawing problems. A minimum of six (6) tests: (4 quizzes, a mid-term and a final examination) Revised 6/30/2016 DFTG-2302 – Machine Drafting - Individual instructors may schedule more test if desired Class and laboratory attendance, active participation in class, professional attitude and growth in terms of technical skills development and teamwork within the laboratory environment shall be taken into consideration. 2 COURSE EVALUATION PROCEDURE: The student will be evaluated and receive a final grade based upon the following criteria: Laboratory work consisting of assigned technical drawing problems. A minimum of 2 tests: (a mid-term and a final examination): NOTE: - Individual instructors may schedule more tests if desired Class and laboratory attendance, active participation in class, professional attitude and growth in terms of technical skill development and teamwork within the laboratory environment shall be taken into consideration. GRADING PROCEDURE: A = 90 –100 B = 80 – 89 C = 70 – 79 D = 60 – 69 F = below 59 The drawing portion of the above evaluation criteria shall be based on the layout, dimensional accuracy, neatness, and timely completion. LATE ASSIGNMENT POLICY: Students are encouraged to turn assignments in on time if at all possible. This allows the instructor to grade the work, return it to the student and the student use the feedback as a learning tool. MAKE-UP TEST/PROJECT POLICY: The student must request a make-up test and it should be scheduled at the earliest possible date following the quiz (or mid-term) missed. NO make-up test is given for the final examination. EXTRA CREDIT: Extra credit work is offered only to assist students that that have a grade range of “D” or “F” at the mid-term break. This work cannot be substituted for regular assignments and can only raise the final grade to a maximum of a “C”. PROGRAM ACCESSIBILITY (ADA): The Houston Community College, Drafting and Design Technology Program are committed to making all aspects of the program accessible to individuals with disabilities. Students with disabilities, as defined by the American with Disabilities Act (ADA), are required to obtain certification of their impairment through the Northeast College ADA Certification Office, located in the Northline Mall Campus. For information call Barbara Morris at, 713-718-8148. CLASS ATTENDANCE: You are expected to attend all lecture classes and labs. You are also responsible for all materials covered in either lecture or lab. In the case of your absence, you must contact the instructor to obtain make-up assignments or arrange make-up testing, either of which can be distributed at the instructor’s discretion. Class attendance is checked daily. The instructor has the authority to drop you from the class for excessive absence. You may be dropped from the class and get an F grade if you are absent more than 12.5% of the instruction hours (lecture and lab). For example: A 12.5% of 96-hour course, meeting twice per week for 3 hours per class meeting equals 12 hours. If you are absent more than 4 class meetings, you may drop. WITHDRAWAL - It is your responsibility to withdraw from the class if you can not complete it. Failure to do so will result in an F grade. Check calendar for the official last day to withdraw. Note: Although it is your responsibility to officially withdraw from a class, please discuss with your instructor first. Consistent class attendance is very important. However, if you have to miss a class for a valid reason, you instructor may be able to help you catch up with the class. Please let your instructor know as soon as possible if you have to miss a class. Valid reason is decided on a case by case basis. Departments and programs governed by accreditation or certification standards may have different attendance policies. RELIGIOUS HOLIDAYS: If you observe a religious holiday and miss class, you must notify your instructor in writing two weeks in advance to arrange to take a test or make up an assignment. A religious holiday is "a holy day observed by a religion whose place of worship is exempt from property taxation under Section 11.20, Tax Code." SCHOLASTIC DISHONESTY: Students are responsible for conducting themselves with honor and integrity in fulfilling course requirements. College System Officials may initiate penalties and/or disciplinary proceedings against a student accused of scholastic dishonesty. "Scholastic dishonesty" includes, but is not limited to, cheating on a test, plagiarism, and collusion. "Cheating" on a test includes: Copying from another student's test paper; Using materials during a test that are not authorized by the person giving the test; Collaborating with another student during a test without authority; Knowingly using, buying, selling, stealing, transporting, or soliciting in whole or part the contents of an un-administered test; Bribing another person to obtain a test that is to be administered. "Plagiarism" means the misuse of another's work and the deliberate incorporation of that work into work you offer for credit. "Collusion" means the unauthorized collaboration with another person in preparing work offered for credit. Determination of scholastic dishonesty will be at the discretion of the instructor. Reference the following web link for additional information: http://www.hccs.com Revised 6/30/2016 DFTG-2302 – Machine Drafting 3 “Notice: Students who repeat a course three or more times may soon face significant tuition/fee increases at HCC and other Texas public colleges and universities. If you are considering course withdrawal because you are not earning passing grades, confer with your instructor/counselor as early as possible about your study habits, reading and writing homework, test-taking skills, attendance, course participation, and opportunities for tutoring or other assistance that might be available.” Course Content Machine Drafting DFTG 2302 Unit 1: Design & Working Drawings. At the end of this unit the student should be able to: 1. Understand the various steps in the design and manufacture of a product. 2. Identify the different types of engineering drawings used in each phase of the design and manufacture process. 3. Correctly fill out a standard company title block for a drawing. 4. Identify and use the various standards and reference books found in a typical drafting room. Unit 2: Dimensioning At the end of this unit the student should be able to: 1. Draw the necessary views of a part for manufacture. 2. Apply dimensions according to accepted drafting standards. Unit 3: Tolerancing At the end of this unit the student should be able to: 1. Understanding tolerancing as applied for part manufacture and assembly. 2. Define the different types of tolerances. 3. Apply tolerances to a machine drawing. Unit 4: Threads & Fasteners At the end of this unit the student should be able to: 1. Define terms relating to screw threads. 2. Apply thread notations to drawings according to ANSI standards. Unit 5: Assembly Drawings At the end of this unit the student should be able to: 1. Create an assembly drawing of a machine part. 2. Create a bill of material list. Unit 6: Gears & Cams At the end of this unit the student should be able to: 1. Define the different types of gears used. 2. Understand the basic working principle of gears. 3. Produce a gear drawing. Unit 7: Manufacturing Processes At the end of this unit the student should be able to: 1. Understand the different types of manufacturing process. 2. Define terms relating to manufacturing processes. 3. Apply welding symbols to a drawing. 4. Understand material specifications and notation Unit 8: Vendor Data Research At the end of this unit the student should be able to: 1. Identify the various composite vendor catalogs for engineering construction materials. 2. Look up information in the catalogs. Unit 9: Drafting Mathematics At the end of this unit the student should be able to: 1. Perform basic mathematic calculations typically used in machine drafting. Revised 6/30/2016 4 DFTG-2302 – Machine Drafting COURSE SCHEDULE AND ASSIGNMENTS (16-Week Semester) WEEK 1 MATERIAL COVERED Day 1 Lecture: Introduction Course Introduction. Discussion of course syllabus, materials required for course, sources of supplies, class attendance, and grading system. Purchase textbook. 13th edition - Read Chapter 12: Working drawings, page 418 Lecture: Design & Working Drawings Read Chapter Summary Read Key Words Answer review questions 1. 2. 3. 4. 5. Design process Sheet sizes Design Layout Production Drawings Title Block Layout Day 1 Lecture: - Tolerancing 2 ASSIGNMENT 1. 2. 3. Purpose Definitions used Fits between mating parts Lab : Draw details of Belt Tightener. 13th Read Chapter 10: Tolerancing, page 334-352 12th Read Chapter 12 Read Chapter Summary Read Key Words Answer review questions Lab : Work on details of Belt Tightener. Day 1 Lecture – Geometric Tolerancing 1. 13th Read Chapter 10: Geometric Tolerancing, page 353-366 12th Read Chapter 12 Geometric Tolerancing Filmstrip Read Chapter Summary Read Key Words Answer review questions Geometric tolerances to belt tightener 7/8 dia hole on top half of frame must be parallel to the 5/8 dia. on the bottom to within .008 MMC. Place the correct datum identification and feature control frame on the detail drawing to indicate this condition. 3 Lab : Work on details of Belt Tightener. Day 1 Lecture - Threads & Fasteners 4 1. 2. 3. Definitions of screw threads Thread Notation How to drawing machine threads 13th Read Chapter 11: Threads & Fasteners, page 376 12th Read Chapter 13 Read Chapter Summary Read Key Words Answer review questions Work on handout sheet on threads. Lab : Work on details of Belt Tightener. Day 1 Lecture – Assembly Drawings 5 1. 2. 3. Types of Assembly Drawings How to Drawing Assembly Drawings How to create a Bill of Materials Day 1 Lecture: Manufacturing Design and Process 6 1. 2. 3. 4. Create Belt Tightener Assembly Drawing Dimensioning Production Drawings Production Process Engineer Materials and Properties Measuring Devices 13th Read Chapter 8: Manufacturing Processes, page 262 Read Chapter Summary Read Key Words Answer review questions Lab : Work on details of Belt Tightener. Revised 6/30/2016 5 DFTG-2302 – Machine Drafting Day 1 Lecture – Reproduction & Control of Drawings. Current trends in Mechanical Technology. 1. The use of computers in drafting. 7 13th Read Chapter 13: Drawing Management, page 494 Read Chapter Summary Read Key Words Answer review questions Review for Midterm Lab : Work on Belt Tightener Assembly Drawing. 8 Day 1: Midterm Turn in Belt Tightener details and Assembly Drawings. Lecture: 1. 2. 3. 13th Read Chapter 17: Gears and Cams, page 594 Gears & Cams Types of Gears Gear Terminology How to create a Gear Drawing Read Chapter Summary Read Key Words Answer review questions Lab : Create working drawing of a spur gear from gear data sheet. Day 1 Lecture: Cams: 9 1. Cam Profile Drawing Day 1 Lecture: Welding, Welding film strip 10 1. 2. 3. Create CAM profile drawing Types of processes Welding symbols Welding Application 13th Read Chapter 22: Welding Representation, page 716 Read Chapter Summary Read Key Words Answer review questions Work handout sheets in class Lab : Create welding drawing. 11 12 Day 1 Lecture: Application of Weld Symbols Work on weld problem Day 1 Lecture – Drafting Mathematics Work on handout assignment 1. 2. Math constants Use of Trigonometry to solve machine drafting problems. Day 1 Lecture – Use of Auxiliary views 13 1. 2. Review use of auxiliary views How to calculate the weight of a part Day 1 Lecture – Vendor Data Research 14 15 16 1. 2. 3. Discuss the grade lab assignment Locator handout problem Work on locator problem Use internet to find technical Product Data Vendor Product Catalogs Engineering Specifications Catalogs Library use Open assignment week: This week to be used as a makeup for spring break during spring semester and holidays during fall semester. All outstanding assignments should be completed this week. Review for final examination All outstanding work must be turned in this week Take Final Exam (2 hrs maximum) Final Exam Revised 6/30/2016 DFTG-2302 – Machine Drafting Houston Community College System 6 Drafting & Design Technology DFTG-2302 –Machine Drafting ADDITIONAL INFO & RULES 1. TEXTBOOK: • Textbook is available at Town & Country Campus Bookstore (713) 468-5300. • Materials on specific topics prepared by the instructor might be handed out, if needed. It is student’s responsibility for making copies of hand-outs from classmates should he/she missed a class meeting. 2. MATERIALS REQUIRED • Drafting instruments (See list) 3. CLASS RULES a. All cellulars and pagers must be turned off during the class meeting. b. Sign in on the Blue Form for every class meeting (not available until the second week) c. Email or call your instructor at least 24 hours if you can not make the class. d. SCHOLASTIC DISHONESTY: Students are responsible for conducting themselves with honor and integrity in fulfilling course requirements. College System Officials may initiate penalties and/or disciplinary proceedings against a student accused of scholastic dishonesty. "Scholastic dishonesty" includes, but is not limited to, cheating on a test, plagiarism, and collusion. Please reference the following web link for additional information: http://northwest.hccs.edu 4. COURSE EVALUATION PROCEDURES: a. Assignments: Unless otherwise specified, each assignment must be completed and turned in within the following week for an up-to-full credit. b. Quizzes: In-class exams will be given during the semester. c. Final Project & Examination: Students will be given a final project and a final exam. 5. STUDENT EVALUATION: Attendance (Lecture session) Drawing assignments Midterm Exam Final Exam Main Project Total: 20% 20% 20% 20% 20% 100% 6. GRADE PROCEDURE: A = 90-100 C = 70-79 F = 59 and below. B = 80-89 D = 60-69 I = Incomplete (*) (*) Fail to submit Final project or not show up at the Final Exam 7. WITHDRAWAL It is student’s responsibility to withdraw from the class. Check calendar for the official last day to withdraw. Revised 6/30/2016