Thermal, mechanical issues continued

advertisement

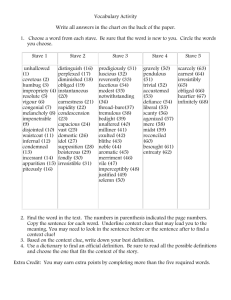

Stave Mechanical Issues Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG1 Basic Questions • Preliminary Indications – Radiation level increasing by factor of 10 • Potential silicon damage increases markedly – Substantial increase in leakage current » Suggesting potentially colder operation – Radiation length issue • Material in detector volume increased beyond original expectations – Impetus for considering fundamental change to detector mounting, detector support, and electronic circuit design » Long, individual stave structure with embedded cooling tubes • Key questions, not all inclusive, could well be: – – – – Is evaporative cooling still possible? If single-phase cooling were desirable, which coolant is rad-hard? Will detector thermal runaway require special cooling considerations? In satisfying the stringent requirements for detector cooling, thermal runaway, detector stability will a long stave structure be low mass? – What are the best construction materials to withstand the radiation environment? Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG2 First Stave Geometry Studied Electronic chip load 108W (Pixel stave 110W 80cm length) Module heating 1mW to 1W over life time 96cm Recommend option being a 2m version of this arrangement, with central support Coolant in and out Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG3 Analysis • Key initial considerations – Stave stiffness (sag and thermal stability) • Negative CTE materials – Composite box (facings) • Positive CTE materials – Cooling tubes (Aluminum or PEEK) – Silicon wafers – Cable bus – BeO hybrid – Ceramic dielectric – Stave Cooling • Length and size of cooling tubes • Thermal resistance of cable bus Meeting UCSC November 10, 2005 Step A: First order calculation of gravity sag Step B: Thermal model of cross-section resulting from Step A ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG4 Gravity Sag • Objective is to check proportions of composite structure – – – – • Sag affected by orientation—we address worst case Sag affected by end support conditions and the unsupported length---we look at simple and fixed end conditions for 1m length (pins at each end provide something in between) Sag is affected by non-structural uniform mass distributed along length---an estimate is made simple support Composite material-use a very modulus graphite fiber, quasiisotropic layer – For present ignore the negative CTE effect Meeting UCSC November 10, 2005 Fixed support ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG5 Stave Sag Item Description Al Tube Al Tube Hollow Composite Partial stave Partial stave Partial stave Partial stave Stave 4mm ID, 0.203mm wall Tube+Liquid Coolant 65.5mm by 5.52mm by 0.203mm Box + tubes (coolant) Box +tubes(coolant)+ modules Box+tubes+modules+bus Box+tubes+modules+bus+BeO Box+tubes+modules+bus+BeO+foam core Simple Support Sag (mm) 2.5 8.5 0.24 0.301 0.361 0.378 0.456 0.477 Delta (mm) 0 0.061 0.060 0.017 0.078 0.021 Composite: 24Msi modulus, ρ=1700kg/m3, 120Msi modulus fiber 60% fraction. Modules: 64mm by 280microns, double sided mounting BeO: 24mm by 64mm 380microns, double sided mounting Foam: carbon, 3% solid fraction Coolant: liquid ρ=1630kg/m3 Meeting UCSC November 10, 2005 Item Description Al Tube Al Tube Hollow Composite Partial stave Partial stave Partial stave Partial stave Stave 4mm ID, 0.203mm wall Tube+Liquid Coolant 65.5mm by 5.52mm by 0.203mm Box + tubes (coolant) Box +tubes(coolant)+ modules Box+tubes+modules+bus Box+tubes+modules+bus+BeO Box+tubes+modules+bus+BeO+foam core ATLAS Upgrade Workshop Silicon Tracker Fixed Support Sag (mm) 0.5 1.699 0.048 0.060 0.072 0.076 0.091 0.095 Delta (mm) 0 0.012 0.012 0.004 0.015 0.004 i T i womiller VG6 Sag Summary If the separation between composite facings is increased, the sag can be decreased within acceptable bounds. This option will force the consideration: how best to package the cooling tubes Stave L=1m, hc=4.6mm, w=6.4cm L=1m, hc=10mm, w=6.4cm L=1m, hc=20mm, w=6.4cm L=2m, hc=20mm, w=6.4cm L=2m, hc=40mm, w=6.4cm Normal Gravity Sag (mm) Simple Fixed Cooling tubes OD 4.6mm 0.397 0.0795 0.107 0.0214 0.032 0.0064 Cooling tubes OD 4.6mm 0.4586 0.0917 0.1441 0.0288 wL4 sag C C=5 for simple support, C=1 for fixed support 384 EI w=uniform loading, N/m L=span length E=Elastic Modulus for composite box I=Moment of Inertia of composite box I h 2 Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG7 Material Properties in Thermal Model Properties used in 3D model Item Silicon Chip Silver-filled AdhesiveA Dielectric (Ceramic) BeO Cable bus Composite Wall CGL 7018 Coolant Tube Coolant Silicon Detector Cable Bus Composite Wall CGL 7018 Coolant Tube Coolant Meeting UCSC November 10, 2005 K-W/mK Station 0 185 (X/Y/Z) 1.55 (X/Y/Z) 5 (X/Y/Z) 240 (X/Y/Z) 0.12 (X/Y/Z) 250 (X)/250 (Y)/1 (Z) 1 (X/Y/Z) 204 (X/Y/Z) Station 1 185 (X/Y/Z) 0.12 (X/Y/Z) 250 (X)/250 (Y)/1 (Z) 1 (X/Y/Z) 204 (X/Y/Z) ATLAS Upgrade Workshop Silicon Tracker Thickness-mm 0.25 0.0508 0.229 0.38 0.125 0.75 0.076 0.3048 0.28 0.125 0.75 0.076 0.3048 i T i womiller VG8 Thermal Model • Model Makeup – – – – – – – – • Array of 6 chips, two on back and one array on front, offset by the stagger in the silicon wafers Silicon wafers 3cm axial with 6.4cm width (280 microns) Electronic chip, 7mm by 10mm (250microns) BeO, 2cm by 6.4cm (380 microns) Dielectric beneath chips, 229microns, k=5W/mK Cable bus, 126microns, k=0.12W/mK Aluminum cooling tubes, 12mil wall PEEK-fiber filled k=0.9W/m*K Objectives – First order determination of gradient • Effects of various material layers • Compare PEEK versus Al coolant tubes • Coolant film gradient Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG9 Thermal Solutions (No Wafer Heating) Aluminum coolant tubes Tube surface referenced to 0ºC 0.5W per chip Side B Side A Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG10 Thermal Solutions (No Wafer Heating) • Solution---Aluminum Cooling Tubes – – Added convective cooling on interior of tube surface (3000W/m2K) • Increase in peak chip temperature of 0.98ºC. An approximate calc of this component is 0.85ºC Notice small temperature variation for center wafer, however essentially uniform • Side A electronic chip array is used to provide proper heating of the cooling tube between the two chip arrays on Side B Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG11 Thermal Solutions (No Wafer Heating) • Solution---PEEK Cooling Tubes – – With convective cooling on interior of tube surface (3000W/m2K) • Peak temperature 8.4ºC, above zero • Increase in peak chip temperature of 2.2ºC. The small temperature variation in center wafer, among areas, suggest a more refined mesh should be considered in the final analysis Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG12 Comments • Thermal Model – Model is a slice from the stave • Unfortunate but the heat load is unbalanced between Side A and Side B • Gives the appearance that the silicon wafer temperature on Side A is not uniform – The middle wafer on Side B has electronics on both sides of a wafer and here the surface temperature is nearly uniform – Deviation of the chip temperature from wafer temperature is about 4ºC for both Al and PEEK cooling tubes. – Heat flux is highest at the chip, but even here it is not very high (0.7W/cm2) • BeO serves as heat spreader – Flux between BeO and cable bus 0.23W/cm2 average • Composite facing spreads heat along the cooling tubes – Facing thickness is about the average thickness for the Pixel stave thermal management surface, but there are now two facings for distributing heat » Thru thickness conductivity is lower, 1W/mK versus 10 to 20W/mK – Heat flux at cooling tube wall reduced further over Pixel stave because of the two pass system within one stave Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG13 Wafer Heating (Next on List) • Wafer Heating – Two sources • Leakage current: peak estimated to be 1W per module from leakage current (temperature dependency) • Free convection for surrounding gas – Open for suggestions on gas temperature to be used – Need to develop more confidence in results of thermal modeling before recommending the coolant inlet temperature • Primary issues are portions chosen for stave structure and cooling tubes – Secondary issues are the material thermal properties being used » Must maintain reality check throughout analysis – What follows: • Refinement in thermal model mesh • Calculation of tendency for thermal runaway, although at the present no strong evidence this will be an issue within present geometry Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG14 Things to Watch For • Stave cross section-2m length – Need greater separation between facings for increased stiffness – Poses interesting issue in integration of cooling tube- simple circular tube geometry not likely • Wider Staves – Again integration of coolant passages – Possible wafer thermal runaway – Temperature gradients • Thermal distortion as a general issue – CTE mismatch of materials – Spatial temperature variations both lengthwise and transverse Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG15 Things to Watch For One must be mindful that stave temperature varies in Z-direction (internal pressure drop and 2-phase convection coefficient varies along stave length) Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG16 Current Emphasis • Structural model of 1m stave – • Compare to analytical solution Set up of thermal and structural coupling solution • Predict CTE effects – Axially – Transverse • Thermal gradient established by location of cooling tubes – Tube geometry for increased separation between stave faces Meeting UCSC November 10, 2005 ATLAS Upgrade Workshop Silicon Tracker i T i womiller VG17