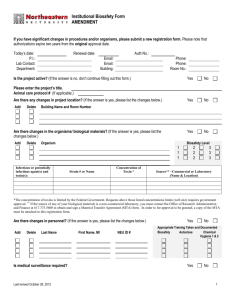

NAU Biosafety Manual

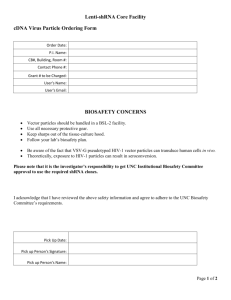

advertisement