QS 9000 Training Slides

advertisement

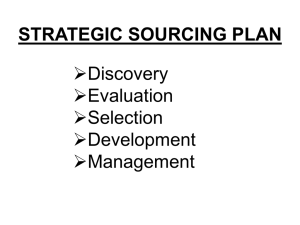

QS 9000 Training Materials Gregory A. Jenkins Total Quality Management ( OISM 470 W ) Smeal College of Business Administration Pennsylvania State University Ice Breaker Form small groups Introduction Field of study Career path What you expect to get from training Select Speaker To effectively summarize information presented about every group member Secretary To record individual responses Quality Perspective What is your definition / perception of quality? According to the oral ice breaker presentations and note taking how would you define its quality. Were your expectations met? Why? Why not? What are some of your suggestions for improvement (documentation and presentation)? Quotes “I think companies will be more selective on who they are placing their business with. If your company is performing better quality-wise and reject-wise, then I think it is going to be the company that is considered for a contract.” Terry Martin, Quality Manager, Plastic Source Inc. (El Paso, TX) "The supplier shall have systems in place to ensure management of appropriate activities during concept development through production.” QS 9000, paragraph 4.1.2.4 Organizational Interfaces QS 9000 Training Outline Introduction Purpose ISO 9000 Background Requirements Real World Examples Interactive Exercise Conclusion Suggested Readings References QS 9000 Purpose Improving relationships to improve quality “The goal of developing your suppliers is based on the need to provide high quality to the customer.” Enhance quality systems for suppliers Eliminate redundant requirements Reduce costs QS 9000 Purpose (continued) Fundamentally different from ISO 9000. Designed to help suppliers to automakers provide evidence of standardized processes for dealing with customers. Major automobile manufacturers setup teams with suppliers to help in development. What is ISO 9000? Advantages Organization for International Standards European standards for quality Standards are broad and vague to adapt to different cultures Does NOT provide framework for organizational improvement and change Companies document quality systems in manuals to facilitate trade through supplier conformance Success has created various other standards such as QS 9000 What is ISO 9000? (continued) Disadvantages Not all countries accept ISO registrars Mainly for exporting firms Barrier to trade Time consuming Costly Difficult for small firms to afford Discourages free thinking and employee empowerment Background Information What is the meaning of QS-9000? Quality System Requirements Common supplier quality standard (Big Three): Chrysler Corporation Ford Motor Company General Motors Corporation Applies to suppliers of: production materials production and service parts heat treating painting and plating other finishing services Does NOT apply to all suppliers of Big Three Background Information (continued) TE-9000 Tooling and Equipment Supplement Internal shorthand as supplement to QS 9000 Worldwide Commitment Released throughout North America, several countries of South America, Europe, Australia and Asia Compliance audits by qualified ISO 9001 registrars: Internal Customer (second-party) Third-party QS 9000 Requirements Management responsibility “defining and documenting its policies for quality along with its objectives and its level of commitment. Clear lines of authority are drawn, assigning responsibility for managing, performing and verifying all work affecting quality.” Training “should be viewed as a strategic imperative for all of a supplier’s personnel. A supplier firm must have documented procedures for assessing training needs and for training all personnel who might impact a company’s quality. Records of past training must also be kept.” QS 9000 Requirements 1. 2. 3. 4. 5. 6. 7. 8. 9. 10. 11. 12. 13. 14. 15. 16. 17. 18. 19. 20. Management responsibility Quality system Contract review Design control Document and data control Purchasing Control of customer-supplied product Product identification and traceability Process control Inspection and testing Control of inspection, measuring and test equipment Inspection and test status Control of nonconforming product Corrective and preventive action Handling, storage, packaging, preservation and delivery Control of quality records Internal quality audits Training Servicing Statistical techniques (continued) QS 9000 Requirements Management Responsibility Quality policy Organization Resources Management representative Organizational interface Business plan Analysis and use of company-level data Customer satisfaction General Information Design and development planning Required skills Organizational, technical interfaces Design input Design output Design review Design verification Design validation Design changes Quality System Requirements Design Control Requirements (continued) General Quality system procedures Quality planning Special characteristics Use of cross-functional teams Feasibility reviews The control plan Name some common requirement processes Common processes Documentation Testing Implementation Processes used to enhance supplier quality systems, eliminate redundant requirements and reduce costs. What are some supply chain priorities? Supply Chain Priorities by auto assemblers, direct suppliers and indirect suppliers order of importance. 1. 2. 3. 4. 5. 6. 7. 8. Consistency Reliability Relationship Technological capability Flexibility Price Service Finances Real World Example I “Supplier Services Inc. (SSI)’s stated goal is to work with small and medium-sized manufacturers to achieve compliance with ISO 9000, QS 9000 and other industryspecific quality system requirements. Their message to those manufacturers or their suppliers is that while it is extremely difficult to manage quality and manufacturing standards when everyone expects fewer people to do the job, SSI is available to fill that organizational void with their own brand of expertise.” Real World Example II “Few businesses survive their first 6 months, much less earn their QS 9000 and ISO 9002 certifications in the first half of the year. Nu Tech Plastics Engineering, a Tier One and Two automotive supplier, not only did both, but it also fulfilled its founder's goal of creating a business niche in taking on so-called problem jobs. Barely three years old, the company has built a $20 million a year business on solving other people's problems. Elektra all-electric molding machines and the company's process tuning shaved 12 seconds from the tool's cycle time.” Interactive Exercise Small groups (company) Design product using given materials Design production process Select Presenter Discuss reasons why your company should be the supplier of choice regarding quality, product and certifications Secretary To record quality production processes Conclusion Why should companies become QS 9000 certified? Enhance quality systems for suppliers Eliminate redundant requirements Reduce costs Suggested Readings QS-9000 In Our Company, Self-Study Course for Personnel: AQA QS-9000 Series (Jack Kanholm) QS-9000 Requirements, 119 Requirements Checklist and Compliance Guide: AQA QS9000 Series (Jack Kanholm) The QS-9000 Answer Book (Radley M. Smith) QS-9000 Quality Systems Handbook (David Hoyle) References American Society for Quality QualityBooks.co.uk Amazon.com “Quality Spending Outlook” Quality; Troy; Dec 2001; Larry Adams. “Future of APQP and PPAP in doubt” Quality; Troy; Jan 2002; Roderick A Munro. Foster, S. Thomas. Managing Quality: An Integrative Approach. Prentice-Hall, Inc. 2001 (pp. 85-90, 258-63; 430-31). “Future of APQP and PPAP in Doubt” Quality; Troy; Jan 2002; Roderick A Munro