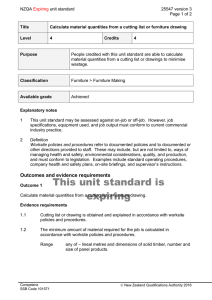

NZQA unit standard 20768 version 3

advertisement

NZQA Expiring unit standard 20768 version 3 Page 1 of 3 Title Explain adhesive use in wood product manufacturing Level 3 Credits 10 Purpose People credited with this unit standard are able to: define properties of adhesives used in wood product manufacturing; define storage and handling requirements of adhesives used in wood product manufacturing; and explain adhesive failures in wood product manufacturing. Classification Solid Wood Manufacturing > Wood Product Manufacturing Skills Available grade Achieved Entry information Recommended: Unit 4548, Laminate straight timber for wood product manufacturing; or Unit 4546, Feed and tail out fingerjointer; or demonstrate equivalent knowledge and skills. Recommended skills and knowledge Explanatory notes Definition Worksite documentation refers to instructions to staff on policy and procedures (including the application of legislation to worksite situations), which are formally documented, and are available for reference at the worksite. Examples are standard operating procedures, specifications, manuals, and manufacturer's information. This unit standard is expiring Outcomes and evidence requirements Outcome 1 Define properties of adhesives used in wood product manufacturing. Evidence requirements 1.1 Definition identifies categories of adhesives used in wood product manufacturing and aligns them with products. Range Competenz SSB Code 101571 categories may include but are not limited to – water resistant, moisture resistant, interior. New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 1.2 20768 version 3 Page 2 of 3 Definition identifies the chemical structure of key adhesives and describes how this impacts on the adhesives’ effectiveness and limitations of use. Range key adhesives may include but are not limited to – formaldehyde, polyvinyl acetate, urethane. 1.3 Definition identifies the properties required of bonds for products in wood product manufacturing and describes how these are achieved. 1.4 Definition identifies the factors that influence the effectiveness of adhesives and describes how these factors are controlled. Outcome 2 Define storage and handling requirements of adhesives used in wood product manufacturing. Evidence requirements 2.1 Definition describes the identification, classification, signage and handling requirements of adhesive chemicals used in wood product manufacturing. 2.2 Definition describes the storage and disposal requirements, for various categories of adhesive used in wood product manufacturing, and identifies how these requirements are met for specific adhesives on a specified wood product manufacturing site. Range categories may include but are not limited to – water resistant, moisture resistant, interior. 2.3 Definition includes procedures and protective equipment required for the safe handling of adhesive chemicals in wood product manufacturing. 2.4 Definition identifies emergency procedures and treatment for adhesive spillage on a wood product manufacturing site. Outcome 3 This unit standard is expiring Explain adhesive failures in wood product manufacturing. Evidence requirements 3.1 Explanation identifies six causes for adhesive failure in wood product manufacturing. 3.2 Explanation describes the physical characteristics that indicate the likely causes of adhesive failure in wood products. 3.3 Explanation describes processes for determining adhesive failure in accordance with worksite documentation. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 3.4 20768 version 3 Page 3 of 3 Explanation includes a report on samples of given products with adhesive failures where the causes of failure are determined in accordance with worksite documentation. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 18 December 2006 31 December 2015 Review 2 18 April 2013 31 December 2015 Rollover 3 16 April 2015 31 December 2018 Consent and Moderation Requirements (CMR) reference 0173 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. This unit standard is expiring Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016