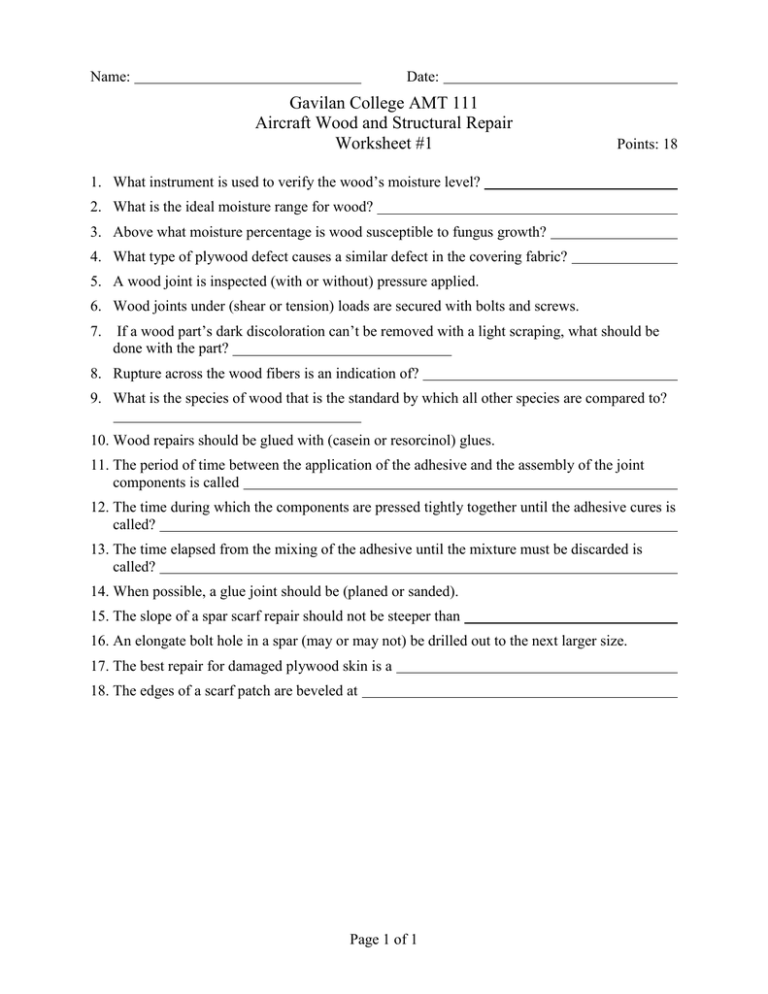

Gavilan College AMT 111 Aircraft Wood and Structural Repair Worksheet #1

advertisement

Name: Date: Gavilan College AMT 111 Aircraft Wood and Structural Repair Worksheet #1 Points: 18 1. What instrument is used to verify the wood’s moisture level? 2. What is the ideal moisture range for wood? 3. Above what moisture percentage is wood susceptible to fungus growth? 4. What type of plywood defect causes a similar defect in the covering fabric? 5. A wood joint is inspected (with or without) pressure applied. 6. Wood joints under (shear or tension) loads are secured with bolts and screws. 7. If a wood part’s dark discoloration can’t be removed with a light scraping, what should be done with the part? 8. Rupture across the wood fibers is an indication of? 9. What is the species of wood that is the standard by which all other species are compared to? 10. Wood repairs should be glued with (casein or resorcinol) glues. 11. The period of time between the application of the adhesive and the assembly of the joint components is called 12. The time during which the components are pressed tightly together until the adhesive cures is called? 13. The time elapsed from the mixing of the adhesive until the mixture must be discarded is called? 14. When possible, a glue joint should be (planed or sanded). 15. The slope of a spar scarf repair should not be steeper than 16. An elongate bolt hole in a spar (may or may not) be drilled out to the next larger size. 17. The best repair for damaged plywood skin is a 18. The edges of a scarf patch are beveled at Page 1 of 1