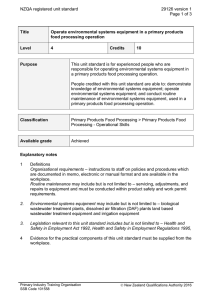

NZQA registered unit standard 17917 version 2 Page 1 of 4

advertisement

NZQA registered unit standard 17917 version 2 Page 1 of 4 Title Roll form metal building products from coated and uncoated coil Level 4 Purpose Credits 20 This unit standard is for people working in the steel manufacturing sector. People credited with this unit standard will be able to: prepare for roll forming metal building products; roll form metal building products from coated and uncoated coil; and complete roll forming of metal building products. Classification Steel Manufacturing > Steel Manufacturing - Cold Working and Forming Available grade Achieved Explanatory notes 1 Definitions Organisational practice refers to documented policies, procedures, quality standards and specifications, and instructions pertaining to folding or forming of metal roofing and cladding accessories at the work site. Safe work practices refer to any safety codes of practice, Health and Safety in Employment Act 1992, and Fire Safety and Evacuation of Buildings Regulations 2006. 2 Range Metal building products include but are not limited to – purlin; and may include but are not limited to – slimline angle, angle brace, girt, stud, channel; for each metal building product, materials may include but are not limited to – low alloy carbon and alloy steels, stainless steels, aluminium alloys, copper, brass, lead; of thicknesses 0.4mm to 3mm; evidence of two is required; equipment may include but is not limited to – roll forming and any other ancillary equipment and/or process used to complete the metal building products. Outcomes and evidence requirements Outcome 1 Prepare for roll forming metal building products. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA registered unit standard 17917 version 2 Page 2 of 4 Evidence requirements 1.1 Documentation is interpreted to determine job requirements. Range 1.2 documentation may include but is not limited to – product specifications, works order, job card, customer’s order, engineering drawings, plans. Coils are selected for rolling in accordance with organisational practice and enables the manufacture of in-specification product. Range selection includes but is not limited to – material, width, grade, gauge, surface coating. 1.3 Coils are handled and moved in accordance with organisational practice to minimise damage and comply with safety requirements. 1.4 Coils are loaded, uncoiled, and threaded on a decoiler in accordance with organisational practice. 1.5 Equipment is set up and prepared for task in accordance with organisational practice. Range set-up includes but is not limited to – settings, tolerances, lubrication, maintenance. 1.6 Potential hazards are identified and preventative action taken in accordance with safe work practices. 1.7 Setting up time meets plant utilisation requirements in accordance with organisational practice. Outcome 2 Roll form metal building products from coated and uncoated coil. Evidence requirements 2.1 Material is roll formed to specifications in accordance with organisational practice. 2.2 Roll forming and cutting processes are monitored to ensure that quality specifications are met in accordance with organisational practice. Range 2.3 monitoring includes but is not limited to – pressures and/or tooling spacing and/or lubrication. Coil ends are welded to ensure roll forming of continuous product in accordance with organisational practice. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA registered unit standard 2.4 17917 version 2 Page 3 of 4 Product is inspected and checked against product specifications and organisational quality standards, and any non-conformance is remedied in accordance with organisational practice. Outcome 3 Complete roll forming of metal building products. Evidence requirements 3.1 Finished product is prepared for delivery or storage in accordance with organisational practice. 3.2 Any leftover items, parts, and materials are disposed of in accordance with organisational practice. 3.3 Used equipment is returned in accordance with organisational practice. 3.4 Any equipment faults are reported in accordance with organisational practice. 3.5 Documentation is completed in accordance with organisational practice. documentation may include but is not limited to – labels, work cards, work orders, job cards, delivery dockets, stock cards. Range Planned review date 31 December 2012 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 19 October 2000 31 December 2012 Rollover and Revision 2 15 March 2012 N/A Consent and Moderation Requirements (CMR) reference 0013 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA registered unit standard 17917 version 2 Page 4 of 4 Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Competenz qualifications@competenz.org.nz if you wish to suggest changes to the content of this unit standard. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016