Demonstrate knowledge of net mending and mend a hole in...

advertisement

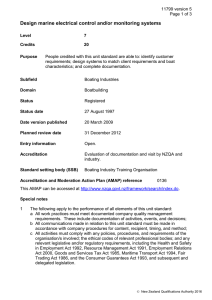

19437 version 2 Page 1 of 3 Demonstrate knowledge of net mending and mend a hole in netting Level 2 Credits 3 Purpose People credited with this unit standard are able to: identify the components of a fishing net; describe net mending tools and equipment; and mend a hole in mesh netting, which includes sideknots and endknots. Subfield Seafood Domain Seafood Vessel Operations Status Registered Status date 23 April 2007 Date version published 23 April 2007 Planned review date 31 December 2011 Entry information Open. Accreditation Evaluation of documentation by NZQA and industry. Standard setting body (SSB) Primary Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0123 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes In this unit standard, the components of the various nets include: seine – cork or float line, lead line, purse line, bunt; set – cork line, lead line, down lines; trawl – wings, square, top panels, lengthener, codend, gussets, selvage, headline, bolshline, bellys. Elements and performance criteria Element 1 Identify the components of a fishing net. Range net includes – seine, set, trawl. Performance criteria New Zealand Qualifications Authority 2016 19437 version 2 Page 2 of 3 1.1 The components of the net are identified using netmakers’ terminology. 1.2 The components of the net are identified in terms of their position on the net. Element 2 Describe net mending tools and equipment. Range needles, knife, sharpening tools. Performance criteria 2.1 The use of the tools and equipment in relation to net mending are described. 2.2 The maintenance requirements of the tools and equipment are described in terms of retaining their proper working order. 2.3 The safety measures required for the use of each of the tools and equipment are described. Element 3 Mend a hole in mesh netting, which includes sideknots and endknots. Range hole no more than six rows deep. Performance criteria 3.1 The mending orientation and techniques used are consistent with the netting, the hole and the efficient repair of the hole. 3.2 The repaired mesh size and shape is consistent with the surrounding netting. 3.3 The twine size and material used for the repair are consistent with the surrounding netting. 3.4 The knots used in the repair are consistent with the surrounding netting and the efficient repair of the hole. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. New Zealand Qualifications Authority 2016 19437 version 2 Page 3 of 3 Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Primary Industry Training Organisation sitostandards@primaryito.ac.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016