Plan and supervise road maintenance contracts

advertisement

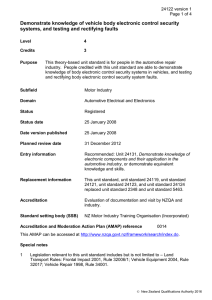

11321 version 2 Page 1 of 6 Plan and supervise road maintenance contracts Level 5 Credits 15 Purpose People credited with this unit standard are able to: identify the requirements of parties involved in the contract; identify work objectives; determine and evaluate the capabilities of available resources; apply planning tools to work activities; identify the site conditions and operational requirements; allocate tasks, instruct subcontractors and suppliers, and report to management on work performance; report to principal’s representative and claim for work done; and measure contract results. Subfield Highway Construction and Maintenance Domain Roading Maintenance Status Registered Status date 25 September 2006 Date version published 25 September 2006 Planned review date 31 December 2012 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Infrastructure ITO Accreditation and Moderation Action Plan (AMAP) reference 0101 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 The following legislation and regulations must be complied with: Health and Safety in Employment Act 1992; Traffic Regulations 1976; and Health and Safety in Employment Regulations 1995. 2 Assessment against this unit standard must take place in a workplace environment. Assessment parameters will be dependent on company and site specific equipment, procedures, and practices. Practices must reflect industry best practice and comply with legislative requirements. 3 Definitions New Zealand Qualifications Authority 2016 11321 version 2 Page 2 of 6 Company requirements include the policy, procedures, and methodologies of the company. They include legislative and regulatory requirements which may apply across the company or to a specific site. Requirements are documented in the company’s health and safety plans, traffic management plans, contract work programmes, quality assurance programmes, policies, and procedural documents. Contract specifications include plans, diagrams, and special technical conditions. They do not include special administrative conditions. As-built refers to what is actually constructed as opposed to that which was planned. Benchmark is the starting set-out position from which control marks are derived. Elements and performance criteria Element 1 Identify the requirements of parties involved in the contract. Performance criteria 1.1 Supervisor’s responsibilities for planning and organising are identified in accordance with company requirements. Range 1.2 accountability, control, limits, delegation. Requirements of government departments are identified in accordance with contract specifications. Range must include – Land Transport New Zealand, Transit NZ; and where specified – Department of Conservation; requirements include – resource consent, traffic safety, permits. 1.3 Requirements of plant hirers and material suppliers are identified in accordance with contract specifications. 1.4 Requirements of adjoining land owners are identified in accordance with contract specifications. 1.5 The client’s requirements are identified in accordance with contract specifications. Range 1.6 cost effectiveness, quality assurance, timetable, budget limits, reports, site access. Requirements of local authorities and service providers are identified in accordance with contract specifications. Range local authorities – district, regional; service providers – power, telephone, gas, water, television. New Zealand Qualifications Authority 2016 11321 version 2 Page 3 of 6 Element 2 Identify work objectives. Performance criteria 2.1 Physical work requirements are identified through a study of the plans. Range 2.2 General and special conditions of contract are identified in accordance with contract specifications. Range 2.3 location, work limits, road reserve boundaries; plans – elevation, cross-section, profile, scale, long-section, notes; requirements – route positions, levels, benchmarks, survey stations, dimensions. general – specifications, schedule of quantities, standards, possession of site, payment claims, completion date; special – specific contract requirements, maintenance period, penalties, response times, variations, disputes. Objectives and outcomes of the work are identified in accordance with contract specifications. Range objectives – general strategy, input limits, reports; outcomes – profitability, delivering within response times, job satisfaction, effect on company reputation. Element 3 Determine and evaluate the capabilities of available resources. Performance criteria 3.1 Available resources are identified in accordance with company requirements. Range 3.2 Capabilities of available workforce are determined in accordance with company requirements. Range 3.3 skills, work attitude, motivation, initiative. Capabilities of available plant and equipment are determined in accordance with company requirements. Range 3.4 workforce, plant and equipment, safety, materials, time, budget, monitoring systems, hiring options. machine outputs, downtime, maintenance. Quality and quantity of available materials and energy are determined in accordance with company requirements. New Zealand Qualifications Authority 2016 11321 version 2 Page 4 of 6 3.5 Capabilities of available resources are evaluated to determine the most efficient option in accordance with company requirements. Range responsibility, coordination, quantity, interdependence, work hours, time of year, activity breakdown, job sharing, nearby work commitments, conjoined work. Element 4 Apply planning tools to work activities. Performance criteria 4.1 Road maintenance activities are organised in accordance with company requirements and contract specifications. Range 4.2 maintenance – sealed roads, unsealed roads; activities – pavement repair, reseal, surface smoothing, bridge repair, drainage, footpath repair, snow and ice removal, slip clearance, drop-out repair, maintenance of roadside furniture and markings, repair of signs and street lighting, vegetation control, shoulder maintenance, tree pruning and removal. The appropriate planning system for the work activity is selected in accordance with company requirements. Range planning systems may include but are not limited to – haul diagram, bar chart, critical path diagram, scheduling, programming, accrual costing, machine hours. Element 5 Identify the site conditions and operational requirements. Performance criteria 5.1 Physical conditions on site are identified with the foreperson. Range 5.2 The site safety plan, traffic management plan, quality assurance plan, and operational requirements are determined on site with the foreperson. Range 5.3 ground conditions, weather conditions, benchmark, control station, work limits, pre-existing defects. office, toilets, waste dump, stockpile areas, machine parking, security, traffic management, environmental considerations, sign type, sign placement, overhead wires, underground services, obstructions, quality management. On-site hazards are identified and controlled in accordance with the Health and Safety in Employment Act 1992. New Zealand Qualifications Authority 2016 11321 version 2 Page 5 of 6 Element 6 Allocate tasks, instruct subcontractors and suppliers, and report to management on work performance. Performance criteria 6.1 The workforce has tasks allocated in accordance with company requirements. Range workforce – foreperson, leading hand, workers. 6.2 Subcontractors are instructed in accordance with company requirements. 6.3 Material suppliers are given instructions including objectives, timetable, and answers to queries, in accordance with company requirements. 6.4 Management is advised of the performance of the work team in accordance with company requirements. Range performance – problems, solutions, advice, options, suggestions, progress relative to contract specifications. Element 7 Report to principal’s representative and claim for work done. Performance criteria 7.1 Reports required by the principal are compiled in accordance with contract specifications. Range 7.2 reports may include but are not limited to – daily, weekly, monthly, performance, features, functions, safety, quality, as-built records, final inspection. Progress claims are rendered for work performed in accordance with contract specifications and company requirements. Element 8 Measure contract results. Performance criteria 8.1 Financial results for the contract are measured and compiled in accordance with company requirements. 8.2 Operational results for the contract are measured and reported in accordance with company requirements. Range productivity, resource utilisation, safety, quality, staff performance evaluation. New Zealand Qualifications Authority 2016 11321 version 2 Page 6 of 6 Please note Providers must be accredited by the Qualifications Authority, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Infrastructure ITO askus@infratrain.co.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016