Service and operate a diesel-electric railcar

advertisement

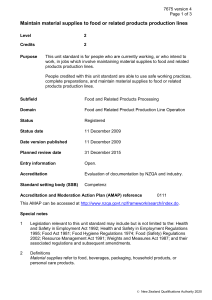

19389 version 2 Page 1 of 5 Service and operate a diesel-electric railcar Level 3 Credits 5 Purpose People credited with this unit standard are able to: ensure diesel-electric railcar is fit for purpose and ready for service; start up, drive, and shut down a diesel-electric railcar; identify faults in a diesel-electric railcar and take appropriate action; demonstrate coupling of diesel-electric railcars for multiple-unit operation; change driving end in a diesel-electric railcar; and prepare a diesel-electric railcar for towing dead. Subfield Rail Transport Domain Rail Operations Status Registered Status date 20 November 2009 Date version published 20 November 2009 Planned review date 31 December 2014 Entry information Prerequisite: Unit 19281, Perform core stationary shunting duties, or demonstrate equivalent knowledge and skills. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Competenz Accreditation and Moderation Action Plan (AMAP) reference 0013 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Assessment against this unit standard is to be carried out within the context of an organisation operating under a current, valid Rail Licence issued in accordance with the provisions of the Railways Act 2005. The organisation’s operating rules, codes, and instructions, referred to in this unit standard, are those the organisation has in place to meet the requirements of the Rail Licence. 2 Legislation relevant to this unit standard includes the Health and Safety in Employment Act 1992. New Zealand Qualifications Authority 2016 19389 version 2 Page 2 of 5 3 Candidates must hold a minimum of the class of licence required for the vehicle being driven and comply with the requirements of the Land Transport (Driver Licensing) Rule 1999. 4 Diesel-electric railcars for this unit standard may include but are not limited to Kawasaki Silver Fern; evidence is required for the servicing and operation of at least one type of dieselelectric railcar. 5 Assessment against this unit standard requires the candidate to drive the railcar to demonstrate operation of the driver controls. Driving and positioning of the railcar is restricted to yard limits, and must not include the conveyance of passengers. 6 Definitions Organisational procedures refer to documents that include: worksite rules, codes, and practices; equipment operating instructions; documented quality management systems; and health and safety requirements. Towing dead refers to a railcar that is without power acting as a conventional rail wagon. Elements and performance criteria Element 1 Ensure diesel-electric railcar is fit for purpose and ready for service. Performance criteria 1.1 Safety check is carried out in accordance with organisational procedures. Range 1.2 Railcar checks are performed in accordance with organisational procedures. Range 1.3 repair book entries, no staff working on or under, presence of warning signs, clear of adjacent equipment. fluid levels, head and auxiliary lights, running gear, brake rigging, brake shoe wear, drawgear, footplates, handrails, steps, external passenger door operation, windows, sand box level, air brake systems, air conditioning system, functioning radio, traction motor leads, inter-car access way, internal automatic-door operation, jumper cables, fresh-water levels. Breakdown and emergency equipment is checked in accordance with organisational procedures. Range may include but is not limited to – detonators, signal flags, spare coupling hooks, emergency airline plugs, spare air hoses, fire extinguisher, air hoses for emergency operation; evidence is required for at least four items of equipment. New Zealand Qualifications Authority 2016 19389 version 2 Page 3 of 5 1.4 Exceptions are handled in accordance with organisational procedures. Range may include but is not limited to – fluid leaks, light failures, excessive wear, missing equipment, internal and/or external damage to railcar, low air pressure, inoperable doors. Element 2 Start up, drive, and shut down a diesel-electric railcar. Performance criteria 2.1 Determine the status of control equipment prior to starting the railcar. Range throttle lever, park brake, air brake systems, instrumentation, switches, circuit breakers, warning devices; evidence is required for at least six types of control equipment. 2.2 Railcar is started in accordance with organisational procedures. 2.3 Railcar safety devices are checked for correct operation in accordance with organisational procedures. Range 2.4 may include but is not limited to – vigilance device, all doors closed indicator. Railcar is driven to a designated position in accordance with job requirements and organisational procedures. Range rate of acceleration, emergency stop, service stop. 2.5 Railcar is secured and stabled in accordance with organisational procedures. 2.6 Railcar is shut down in accordance with organisational procedures. Element 3 Identify faults in a diesel-electric railcar and take appropriate action. Performance criteria 3.1 Faults are identified in accordance with organisational procedures. Range may include but is not limited to – insufficient air pressure, excessive motor noise, excessive exhaust emissions, malfunctioning auxiliary equipment, failure to start or idle, railcar fails to move with increased engine revolutions; evidence is required for at least two railcar faults. New Zealand Qualifications Authority 2016 19389 version 2 Page 4 of 5 3.2 The status of warning devices is interpreted in accordance with organisational procedures. Range 3.3 may include but is not limited to – warning lights, audible alarms. Railcar faults are corrected and/or reported for further action in accordance with organisational procedures. Element 4 Demonstrate coupling of diesel-electric railcars for multiple unit operation. Range two compatible railcars. Performance criteria 4.1 Coupling of railcars is in accordance with organisational procedures. Range 4.2 Control mechanisms are set for coupled operation in accordance with operational requirements and organisational procedures. Range 4.3 mechanical coupling, air brake coupling, electrical control systems. air brakes, reverser, throttle. Procedures for securing non-operating cab control equipment are described in accordance with organisational procedures. Element 5 Change driving end in a diesel-electric railcar. Performance criteria 5.1 Railcar is secured in accordance with organisational procedures. 5.2 Control handles are set and removed from non-operating cab in accordance with organisational procedures. 5.3 Lighting is set in accordance with organisational procedures. Range 5.4 headlight, tail-light, cab lighting. Operating cab is prepared for railcar operation in accordance with organisational procedures. Range may include but is not limited to – control handles, lighting, communication equipment. New Zealand Qualifications Authority 2016 19389 version 2 Page 5 of 5 Element 6 Prepare a diesel-electric railcar for towing dead. Performance criteria 6.1 Preparations for towing dead are in accordance with organisational procedures. Range mechanical couplings, air brake equipment. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact Competenz info@competenz.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016