Assist sows to farrow under supervision in an indoor pork... unit

advertisement

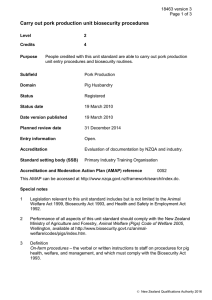

22073 version 2 Page 1 of 4 Assist sows to farrow under supervision in an indoor pork production unit Level 3 Credits 10 Purpose People credited with this unit standard are able, under supervision, to: prepare the farrowing area for a new intake of sows; move sows to the farrowing area; monitor sows during farrowing; and assist sows to farrow, for an indoor pork production unit. Subfield Pork Production Domain Pig Husbandry Status Registered Status date 19 March 2010 Date version published 19 March 2010 Planned review date 31 December 2014 Entry information Open. Replacement information This unit standard and unit standard 22074 replaced unit standard 4447. Accreditation Evaluation of documentation and visit by NZQA, industry and teaching professional in the same field from another provider. Standard setting body (SSB) Primary Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0052 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Performance of all aspects of this unit standard should comply with the New Zealand Ministry of Agriculture and Forestry, Animal Welfare (Pigs) Code of Welfare 2005, Wellington, available at http://www.biosecurity.govt.nz/animalwelfare/codes/pigs/index.htm. New Zealand Qualifications Authority 2016 22073 version 2 Page 2 of 4 2 Definitions On-farm procedures – the verbal or written instructions to staff on procedures for pig health, welfare, and management. Pork production unit – collective term for several pork production sections. For example, a farrowing section, a grower section, and a dry sow section together make up a pork production unit. Elements and performance criteria Element 1 Prepare the farrowing area for a new intake of sows in an indoor pork production unit under supervision. Performance criteria 1.1 Farrowing area is cleaned and prepared without damage to equipment and fittings in accordance with on-farm procedures. 1.2 Farrowing area is sanitised and safety procedures are observed in accordance with on-farm procedures. Range 1.3 Equipment and fittings are checked to ensure they are operational in accordance with manufacturer’s instructions and on-farm procedures. Range 1.4 disinfect, fumigate. heaters, lights, environmental control equipment, drinkers. Malfunctions are repaired and/or reported in accordance with on-farm procedures. Element 2 Move sows to the farrowing area in an indoor pork production unit under supervision. Performance criteria 2.1 Sows due to be moved to farrowing area are identified in accordance with onfarm procedures. 2.2 Farrowing area is checked for readiness to receive sows in accordance with onfarm procedures. Range 2.3 may include but is not limited to – clean and dry, creep heaters working, drinkers working, room temperature meets sow needs. Sows are treated in accordance with on-farm procedures. Range may include but is not limited to – wash, disinfect, parasite control. New Zealand Qualifications Authority 2016 22073 version 2 Page 3 of 4 2.4 Sows are moved into farrowing area with minimal stress and without injury to animals and handler(s). Element 3 Monitor sows during farrowing in an indoor pork production unit under supervision. Performance criteria 3.1 Imminent farrowing is identified by the physical and behavioural signs. 3.2 Interval between births is monitored and reported in accordance with on-farm procedures. 3.3 Sow's udder is checked for availability of milk and signs of mastitis, and problems reported and treated in accordance with on-farm procedures. 3.4 Information is recorded in accordance with on-farm procedures. Element 4 Assist sows to farrow in an indoor unit under supervision. Performance criteria 4.1 Internal examination of sows is carried out as directed. Range 4.2 Sows are treated following internal examination as directed, and records are maintained in accordance with on-farm procedures. Range 4.3 antibiotic, oxytocin. Problems during farrowing are identified and remedial action taken as directed. Range 4.4 constriction, piglets, afterbirth. signs – behavioural, physical. Piglets are assisted in accordance with on-farm procedures. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. New Zealand Qualifications Authority 2016 22073 version 2 Page 4 of 4 Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Primary Industry Training Organisation standards@primaryito.ac.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016