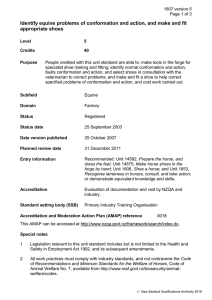

Remove and replace a shoe on a horse

1597 version 5

Page 1 of 3

Remove and replace a shoe on a horse

Level 4

Credits 6

Purpose This unit standard is for people involved with training horses where 'first aid shoeing' is used to enable the horse to continue until qualified help arrives.

People credited with this unit standard are able to: prepare a horse and remove a shoe; assess a hoof and replace a shoe on a horse; and attend to post-shoeing activities.

Subfield Equine

Domain

Status

Status date

Date version published

Harness Racing

Registered

23 April 2008

23 April 2008

Planned review date

Entry information

31 December 2013

Open

Accreditation Evaluation of documentation and visit by NZQA and industry.

Standard setting body (SSB) Primary Industry Training Organisation

Accreditation and Moderation Action Plan (AMAP) reference 0018

This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do.

Special notes

1 Legislation relevant to this unit standard includes but is not limited to the Health and

Safety in Employment Act 1992, and its subsequent amendments.

2 Stable procedures are the documented practices and polices required within a particular workplace, and do not contravene the Code of Recommendations and

Minimum Standards for the Welfare of Horses (Wellington: Ministry of Agriculture and

Forestry,1993); or available at http://www.biosecurity.govt.nz/animalwelfare/codes/horses/index.htm

.

New Zealand Qualifications Authority 2020

1597 version 5

Page 2 of 3

3 For this unit standard the practical assessment evidence must be provided in the context of a commercial business operation under normal working conditions.

4 Element 2 reflects the 'first aid' measures only used to replace the shoe to prevent further damage to the foot until a farrier arrives.

Elements and performance criteria

Element 1

Prepare a horse and remove a shoe.

Performance criteria

1.1 Correct equipment is assembled.

Range may include but is not limited to

– hoof knife, rasp, shoe puller, nail puller, clinches, hammer, nails.

1.2 Horse is held with sufficient length of rope to remain in a calm and comfortable position while standing.

1.3

Horse’s foot is picked up and held in a position comfortable for the horse and handler.

1.4 Shoe and nails are removed without causing damage to hoof and in accordance with stable procedures.

1.5

Element 2

Hoof is cleaned to remove foreign matter, and foot replaced on the ground without damage to the hoof.

Assess a hoof and replace a shoe on a horse.

Range temporary until a farrier arrives.

Performance criteria

2.1 Four hoof problems are identified in terms of probable cause and remedial action.

Range stone bruise, punctured sole, thrush, cracked heels, mud fever, sandcracks, corns, seedy toe, pricked foot.

2.2

2.3

Assessment of hoof damage determines viability of replacing shoe.

Surface of shoe in contact with hoof is level, smooth, in contact with hoof around edge, and shoe shape corresponds with shape of grounded surface of hoof.

New Zealand Qualifications Authority 2020

1597 version 5

Page 3 of 3

2.4 Shoe is nailed to hoof in accordance with stable procedures.

Range using white line as a guide, with a maximum of four nails (two on each side of foot), using nail size suitable for the shoe, with bevelled side of nail facing centre hoof.

2.5 Nails are finished in accordance with stable procedures.

Range by cutting and bending on hoof wall to ensure tight shoe fit, with protruding areas filed smooth.

2.6

Element 3

Record of actions carried out is maintained and made available to farrier in accordance with the farrier’s requirements.

Attend to post-shoeing activities.

Performance criteria

3.1 Debris from shoeing is moved to designated place in accordance with stable procedures.

3.2 Shoeing tools are cleaned and stored in a dry, accessible place in accordance with stable procedures.

3.3 Horse is returned to area as directed by the supervisor.

Please note

Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment.

Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards.

Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards.

Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The

AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements.

Comments on this unit standard

Please contact the Primary Industry Training Organisation standards@primaryito.ac.nz if you wish to suggest changes to the content of this unit standard.

New Zealand Qualifications Authority 2020