National Certificate in Footwear (Level 3) with strands in Clicking,

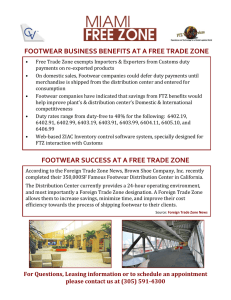

advertisement

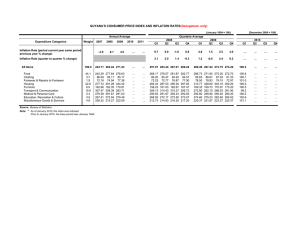

NQF Ref 0225 Version 5 Page 1 of 12 National Certificate in Footwear (Level 3) with strands in Clicking, Closing, Bottom Stock, and Making and Lasting Level 3 Credits 110 Purpose The National Certificate in Footwear (Level 3) with strands in Clicking, Closing, Bottom Stock, and Making and Lasting recognises the acquisition by the holder, of knowledge of key operations of one of the shoe-making departments, together with some practical knowledge of operations in departments apart from that of the strand chosen, and/or the acquisition of interpersonal communications and pertinent core generic unit standards that are important for those who already exercise or may soon exercise responsibility for other staff. Gaining this qualification will be evidence that the holder is a skilled, versatile operator in one of the footwear departments of Clicking, Closing, Bottom Stock, Lasting, Making, and Shoe Room and it will provide the basis for continuity in the training process towards the National Certificate in Footwear (Level 4) with strands in Pattern Cutting, Clicking, Closing, Bottom Stock, and Making and Lasting [Ref: 0226]. Special Notes It is recommended that candidates already hold the following qualification: National Certificate in Footwear (Level 2) [Ref: 0224]; or have demonstrated equivalent knowledge and skills. Credit Range Level 1 credits Level 2 credits Level 3 or above credits Minimum totals Level 2 credits Level 3 or above credits Minimum totals Competenz SSB Code 101571 Core Compulsory 8 9 25 42 Strands Clicking Closing 0-6 49-55 55 0-18 37-55 55 Core Elective 0-13 0-13 0-13 13 Bottom Stock 13-24 31-42 55 Making and Lasting 0-29 26-55 55 New Zealand Qualifications Authority 2016 NQF Ref 0225 Version 5 Page 2 of 12 Requirements for Award of Qualification The qualification will be awarded to people who are credited with a minimum total of 110 credits composed of: All core compulsory unit standards, and a minimum of 55 elective credits from the elective strand set chosen, and the balance of credits from the core elective unit standards available. Award of NQF Qualifications Credit gained for a standard may be used only once to meet the requirements of this qualification. Unit standards and achievement standards that are equivalent in outcome are mutually exclusive for the purpose of award. The table of mutually exclusive standards is provided in the Qualifications Authority Rules and Procedures publications available at www.nzqa.govt.nz/ncea/. Reviewed standards that continue to recognise the same overall outcome are registered as new versions and retain their identification number (Id). Any version of a standard with the same Id may be used to meet qualification requirements that list the Id and/or that specify the past or current classification of the standard. Detailed Qualification Requirements Compulsory All the standards listed below are required. Field Core Generic Subfield Core Generic Domain Self-Management Id Title 12349 Demonstrate time management Level 2 Credit 3 Domain Work and Study Skills Id Title 543 Start work in a new workplace Level 1 Credit 3 Field Health Subfield Occupational Health and Safety Domain Occupational Health and Safety Practice Id Title 497 Protect health and safety in the workplace Level 1 Credit 1 Field Humanities Subfield Communication Skills Domain Interpersonal Communications Id Title 1312 Give oral instructions in the workplace 11097 Listen to gain information in an interactive situation Level 3 3 Credit 3 3 Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NQF Ref 0225 Version 5 Page 3 of 12 Domain Reading Id Title 2977 Read texts for practical purposes Level 1 Credit 4 Domain Writing Id Title 3491 Write a report Level 3 Credit 4 Level 2 Credit 3 2 4 3 9 3 6 Level 3 Credit 12 Level 3 3 3 3 3 2 Credit 6 12 18 18 6 3 3 2 12 3 Field Manufacturing Subfield Footwear and Leather Trades Domain Footwear Id Title 3336 Demonstrate knowledge of footwear terms, components and groups 3337 Describe the purposes and production of lasts 3342 Inspect part finished and finished footwear for quality acceptance 3348 Demonstrate knowledge of footwear manufacture and construction Clicking Strand A minimum of 55 credits is required from the following standards. Field Manufacturing Subfield Footwear and Leather Trades Domain Leather – Bottom Stock, Making and Lasting Id Title 5025 Cut footwear bottom stock components from leather Domain Id 3359 3360 3361 3367 3368 3371 3372 3375 Leather – Cutting and Closing Title Cut non-leather materials by clicking press Cut pigmented side leathers by clicking press Cut grain fashion leathers by clicking press Cut materials by hand clicking knife Perform band splitting operations Set up cutting equipment and service cutting area prior to cutting materials Cut suede and nubuck leathers by clicking press Perform press punching operations Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NQF Ref 0225 Version 5 Page 4 of 12 Closing Strand A minimum of 55 credits is required from the following standards. Field Subfield Domain Id 3365 3368 3369 3370 3376 3379 8108 8109 8110 8111 8112 8113 8122 8124 Manufacturing Footwear and Leather Trades Leather – Cutting and Closing Title Perform folded and bagged edge treatments Perform band splitting operations Run on binding to footwear uppers Perform post trimming operations on the round Perform skiving operation Perform turnover binding operation Set up and use a single needle lockstitch sewing machine in the footwear industry Join pieces of leather or other material by zig zag seam in the footwear or associated industries Close footwear backseams Make a gathered seam for footwear using an industrial sewing machine Join two pieces of material to make a sprung seam for footwear uppers Apply decorative stitching to marks on footwear uppers Operate a computer controlled sewing machine on footwear uppers Trim footwear linings Level 3 3 3 3 3 3 2 Credit 21 6 6 12 21 15 6 2 3 2 3 3 12 3 6 2 3 6 6 3 3 Level 3 2 3 3 3 Credit 12 3 6 9 9 2 2 2 6 3 9 Bottom Stock Strand A minimum of 55 credits is required from the following standards. Field Subfield Domain Id 5025 5031 5032 5033 5039 5041 5042 5043 Manufacturing Footwear and Leather Trades Leather – Bottom Stock, Making and Lasting Title Cut footwear bottom stock components from leather Pre-mould footwear stiffeners Reduce soles and insoles Rand lay soles Perform skiving operation for bottom stock, stiffeners, and toe puffs Perform insole recessing and waist reducing operation Edge trim sole prior to attachment Cover heels Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NQF Ref 0225 Version 5 Page 5 of 12 Domain Leather – Cutting and Closing Id Title 3359 Cut non-leather materials by clicking press 3371 Set up cutting equipment and service cutting area prior to cutting materials Level 3 2 Credit 6 3 Level 2 Credit 3 Level 3 3 3 3 3 3 2 2 3 Credit 15 9 12 12 9 12 2 2 6 3 3 3 2 3 2 2 2 2 2 3 3 6 9 6 9 18 3 2 2 3 3 6 6 3 6 4 9 Making and Lasting Strand A minimum of 55 credits is required from the following standards. Field Manufacturing Subfield Footwear and Leather Trades Domain Footwear Id Title 3347 Apply adhesives to footwear components Domain Id 5027 5028 5029 5030 5034 5036 5037 5038 5040 5044 5045 5046 5047 5048 5049 5050 5051 5052 8116 8117 8118 8119 8120 Leather – Bottom Stock, Making and Lasting Title Pull and last footwear foreparts Force last uppers Attach soles by cement Rough footwear bottoms manually Back part mould uppers Attach heels by nailing Attach insoles by machine Slip last Assemble footwear components to work tickets and bulk instructions Seat last by machine Tack side last by machine Burnish, bruise, and polish uppers Perform sock insertion operations Clean, dress, and spray footwear in a shoe room Perform ancillary shoe room operations Quarter reform shoes in shoe room Make up shoe boxes Pack shoes and attach identification labels and/or tags Attach steel toe caps to industrial footwear Direct mould soles to footwear uppers Set up and close down a rubber vulcanising machine and prepare for moulding footwear soles Set up and close down a PVC moulding machine and prepare for moulding on footwear soles Set up and close down a PU moulding machine and prepare for moulding on footwear soles Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NQF Ref 0225 Version 5 Page 6 of 12 Core Elective The balance of credits to achieve the minimum total of 110 credits for this qualification selected from the following standards. Field Business Subfield Business Administration Domain Business Administration Services Id Title 334 Operate inventory administration systems to record and monitor inventory activities Field Subfield Domain Id 2780 2781 2783 Level 3 Credit 5 Level 2 2 3 Credit 9 3 3 Level 1 Credit 2 2 3 2 2 Level 1 Credit 2 Level 2 Credit 3 5 2 3 3 Level 2 Credit 4 Computing and Information Technology Computing Generic Computing Title Operate and maintain a personal computer system Manage and protect data in a personal computer system Demonstrate knowledge of the components of personal computer systems Field Core Generic Subfield Core Generic Domain Self-Management Id Title 12348 Demonstrate knowledge of anger and options for dealing with anger issues 12353 Use personal banking services and personal services common to banks and other financial institutions 12355 Demonstrate knowledge of stress and ways of dealing with it Domain Work and Study Skills Id Title 10780 Complete a work experience placement Field Humanities Subfield Communication Skills Domain Interpersonal Communications Id Title 9677 Participate in groups and/or teams to gather ideas and information 9678 Conduct formal meetings 10791 Participate in informal meetings Domain Reading Id Title 2989 Read and assess texts to gain knowledge Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NQF Ref 0225 Version 5 Page 7 of 12 Domain Writing Id Title 3483 Fill in a form 3490 Write an incident report Level 1 1 Credit 4 3 Field Subfield Domain Id 3338 3339 3340 3341 3343 Level 3 4 4 4 4 Credit 6 12 9 6 6 4 3 4 6 6 12 2 4 2 4 4 3 9 2 6 6 Level 2 3 3 3 3 3 3 2 3 3 3 3 3 2 2 3 Credit 6 12 9 15 9 12 12 3 6 9 9 12 12 2 2 9 3 6 3344 3345 3346 3347 3349 3350 3351 3352 Domain Id 5024 5025 5026 5027 5028 5029 5030 5031 5032 5033 5034 5035 5036 5037 5038 5039 5040 Manufacturing Footwear and Leather Trades Footwear Title Inspect incoming leather against purchase specification Compile footwear design and manufacturing specifications Specify non-leather materials used in footwear uppers Specify materials used in footwear soles Specify solvents and adhesives for footwear materials and operations Assess usability of leathers for costing purposes Calculate material allowances for footwear Test safety footwear to Australian and New Zealand joint standards Apply adhesives to footwear components Specify types of leather used in footwear uppers Take foot measurements and relate to various sizing scales Specify materials used in footwear heels and platforms Specify materials used in footwear insoles, backers and shanks Leather – Bottom Stock, Making and Lasting Title Perform ancillary insole operations Cut footwear bottom stock components from leather Bind and cover insoles Pull and last footwear foreparts Force last uppers Attach soles by cement Rough footwear bottoms manually Pre-mould footwear stiffeners Reduce soles and insoles Rand lay soles Back part mould uppers Last uppers by hand Attach heels by nailing Attach insoles by machine Slip last Perform skiving operation for bottom stock, stiffeners, and toe puffs Assemble footwear components to work tickets and bulk instructions Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NQF Ref Id 5041 5042 5043 5044 5045 5046 5047 5048 5049 5050 5051 5052 5053 5054 5055 5056 5057 5058 8116 8117 8118 8119 8120 Domain Id 3359 3360 3361 3362 3363 3364 3365 3366 3367 3368 3369 3370 3371 0225 Version 5 Page 8 of 12 Title Perform insole recessing and waist reducing operation Edge trim sole prior to attachment Cover heels Seat last by machine Tack side last by machine Burnish, bruise, and polish uppers Perform sock insertion operations Clean, dress, and spray footwear in a shoe room Perform ancillary shoe room operations Quarter reform shoes in shoe room Make up shoe boxes Pack shoes and attach identification labels and/or tags Cement footwear bottoms manually and attach fillers Rough round shoe bottoms Outsole stitch shoes Scour sole edges Rough footwear bottoms by auto rougher Cement footwear bottoms by auto-cementing machine and attach fillers Attach steel toe caps to industrial footwear Direct mould soles to footwear uppers Set up and close down a rubber vulcanising machine and prepare for moulding footwear soles Set up and close down a PVC moulding machine and prepare for moulding on footwear soles Set up and close down a PU moulding machine and prepare for moulding on footwear soles Level 2 2 2 3 3 3 2 3 2 2 2 2 3 2 3 2 2 2 Credit 6 3 9 6 9 6 9 18 3 2 2 3 6 6 18 6 6 6 2 3 3 3 6 6 3 6 4 9 Level 3 3 3 2 2 2 3 2 3 3 3 3 2 Credit 6 12 18 2 3 2 21 9 18 6 6 12 3 Leather – Cutting and Closing Title Cut non-leather materials by clicking press Cut pigmented side leathers by clicking press Cut grain fashion leathers by clicking press Perform stripping operations Perform stitch marking operations Perform tape reinforcing operations in footwear manufacture Perform folded and bagged edge treatments Perform specialist footwear closing operations Cut materials by hand clicking knife Perform band splitting operations Run on binding to footwear uppers Perform post trimming operations on the round Set up cutting equipment and service cutting area prior to cutting materials Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NQF Ref Id 3372 3373 3374 3375 3376 3377 3378 3379 8108 8109 8110 8111 8112 8113 8121 8122 8123 8124 Domain Id 3353 3354 3355 3356 3357 3358 8114 8115 0225 Version 5 Page 9 of 12 Title Cut suede and nubuck leathers by clicking press Perform inking operations Perform embossing, and foil stamping operations for footwear Perform press punching operations Perform skiving operation Attach linings and interlinings Attach toe puffs Perform turnover binding operation Set up and use a single needle lockstitch sewing machine in the footwear industry Join pieces of leather or other material by zig zag seam in the footwear or associated industries Close footwear backseams Make a gathered seam for footwear using an industrial sewing machine Join two pieces of material to make a sprung seam for footwear uppers Apply decorative stitching to marks on footwear uppers Operate an automatically controlled bar tack sewing machine on footwear uppers Operate a computer controlled sewing machine on footwear uppers Lay out work, receive, dispose, and check work in a closing room Trim footwear linings Leather – Design and Patternmaking Title Cut standard patterns for uppers Produce and cut footwear upper patterns Produce and cut footwear bottom stock patterns Grade footwear patterns by machine Demonstrate knowledge of last coordination Demonstrate knowledge of footwear pattern grading systems Demonstrate knowledge of a Footwear CADCAM system and digitise shapes into the system Produce and grade footwear patterns using a CADCAM system Level 3 2 2 2 3 2 2 3 2 Credit 12 4 3 3 21 3 2 15 6 2 3 2 3 3 12 3 6 2 2 6 3 3 6 2 2 3 3 Level 4 4 4 4 3 4 3 Credit 9 9 6 6 3 6 3 4 24 Transition Arrangements Version 5 Version 5 was issued following the transfer of responsibility for standards setting in the footwear and leather trades sector from the Leather Industry Training Organisation to Competenz. For detailed information see Review Summaries on the Qualifications Authority website. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NQF Ref 0225 Version 5 Page 10 of 12 This qualification contains standards that replace earlier standards. For the purposes of this qualification people who have gained credit for the expiring standards are exempt from the requirement to gain credit for the replacement standards. Credit for 500 502 503 541 545 1278 1300 1301 1302 2982 3502 Exempt from 10780 12348 12349 12353 12355 3491 9677 10791 9678 2977 11097 Previous versions of the qualification Version 4 was issued to reflect the review of the Computing unit standards. Version 3 was issued to reflect the review of the Footwear and Leather Trades unit standards and the renaming of field Business. Version 2 was issued to reflect the reviews of Core Generic, Computing, Business Administration and Communication Skills unit standards. NQF Registration Information Process Registration Revision Revision Revision Revision Version 1 2 3 4 5 Date October 1996 May 1998 February 2001 November 2002 November 2004 Last Date for Award 31 December 2005 31 December 2005 31 December 2005 31 December 2005 N/A Standard Setting Body Competenz PO Box 9005 Newmarket Auckland 1149 Telephone Fax Email Website 0800 526 1800 09 539 9899 info@competenz.org.nz http://www.competenz.org.nz/ Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NQF Ref 0225 Version 5 Page 11 of 12 Any person or organisation may contribute to the review of this qualification by sending feedback to the standard setting body at the above address. The review of this qualification is planned to take place in 2005. Other standard setting bodies whose standards are included in the qualification New Zealand Industry Training Organisation – Industrial Health and Safety Advisory Group NZQA Certification The certificate will display the logos of the Qualifications Authority and Competenz. Classification This qualification is classified according to the NQF classification system and the New Zealand Standard Classification of Education (NZSCED) system as specified below. NQF Classification Code Description 1235 Manufacturing/Footwear and Leather Trades/Footwear NZSCED Code Description 030109 Engineering and Related Technologies/Manufacturing/ Footwear Making Quality Management Systems Providers and Industry Training Organisations must be accredited by a recognised Quality Assurance Body before they can register credits from assessment against standards. Accredited providers and Industry Training Organisations assessing against standards must engage with the moderation system that applies to those standards. Accreditation requirements and the moderation system are outlined in the associated Accreditation and Moderation Action Plan (AMAP) for each standard. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NQF Ref 0225 Version 5 Page 12 of 12 Prerequisite Diagram 3371 3336 Level 2 3348 5025 3359 3345 3360 3372 3361 Level 3 3339 3340 3344 3342 3349 3351 3352 3341 Level 4 Competenz SSB Code 101571 New Zealand Qualifications Authority 2016