NZQA unit standard 21615 version 4

advertisement

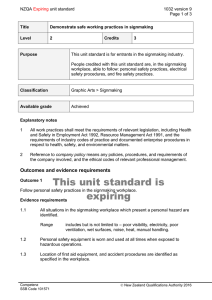

NZQA Expiring unit standard 21615 version 4 Page 1 of 6 Title Demonstrate industry knowledge for the fibreboard packaging industry Level 3 Credits 15 Purpose People credited with this unit standard are able to use terms and vocabulary applicable to the fibreboard packaging industry; demonstrate mathematical skills applicable to fibreboard packaging production; demonstrate knowledge of: the machinery and equipment used in fibreboard packaging production, the importance of maintaining workflow through production, storage and/or warehousing systems in use in the workplace, and board grammages, flutes, and paper types; identify styles of cases and fittings; demonstrate knowledge of the factors contributing to production costs; explain the importance of confidentiality; and follow written instructions and complete forms. Classification Fibreboard Packaging > Fibreboard Packaging Production Available grade Achieved Explanatory notes 1 All workplace practices must meet any applicable and recognised codes of practice, and documented workplace health, safety, and environmental procedures for personal, product, workplace health, safety, and environmental matters, and the obligations required under current law including the Health and Safety in Employment Act 1992, Hazardous Substances and New Organisms Act 1996, Resource Management Act 1991, Privacy Act 1993 and their subsequent amendments. 2 Workplace practices refer to the documented procedures for the machine and/or workplace. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 21615 version 4 Page 2 of 6 Outcomes and evidence requirements Outcome 1 Use terms and vocabulary applicable to the fibreboard packaging industry. Evidence requirements 1.1 Terms and vocabulary applicable to the fibreboard packaging industry are defined. Range 1.2 may include but is not limited to – adhesion, artwork, blank, bleed, board, box stamp, bulge, bundle, butt, calliper, carton, case, closure, coating, converting, corrugator, corrugated fibreboard, crease, creaser, cut-off, deckle, delamination, die cut, divider, divisions, double backer, double wall board, duo arch, enduro board, facings, feed, fibreboard, fill-in, flange, flaps, flexographic, flexo folder gluer (FFG), flute, flute direction, glue-flap, hand-hold, hot-melt, half slotted case style (HSC), kraft, lacing, laminator, lap, layer, liner, linearboard, make ready, manufacturer’s joint, medium, offset, overlap, pallet, paperboard, partitions, panel, perforations, pre-printed liner, printer-slotter, proof, regular slotted case (RSC), recyclable, register, rule, sample, score, sections, sheet, single face, single facer, single wallboard, slit, slitter, slot, slotter, solid fibreboard, staple, stitch, stitch-lap, stereo, style, takeoff, tape, tray, trim, twin-cushion, unlaced, vent holes, warp. Terms and vocabulary applicable to fibreboard packaging production are used in the process being undertaken. Outcome 2 Demonstrate mathematical skills applicable to fibreboard packaging production. Evidence requirements 2.1 Problems are solved using addition, subtraction, multiplication, and division. 2.2 Scales are read and calculations made to ensure job requirements are met. 2.3 Calculations used meet requirements of the processes and operations being undertaken. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 21615 version 4 Page 3 of 6 Outcome 3 Demonstrate knowledge of the machinery and equipment used in fibreboard packaging production. Range may include but is not limited to – corrugator, printer, flat bed or platen die cutter, rotary die cutter, FFG, specialty gluer, slotter, creaser. Evidence requirements 3.1 Machinery and equipment used in fibreboard packaging production are identified, and described in terms of their functions. Outcome 4 Demonstrate knowledge of the importance of maintaining workflow throughout production. Evidence requirements 4.1 Importance of flow of work from the time a job is raised through production and distribution is described. 4.2 A selected job is explained in terms of its workflow from start to finish. Outcome 5 Demonstrate knowledge of the storage and/or warehousing systems in use in the workplace. Evidence requirements 5.1 Storage and/or warehousing systems located in the workplace are described. Range 5.2 Functions and services of storage and/or warehousing systems are described. Range 5.3 storage systems may include but are not limited to – reel store, board store, stereo store, die store, ink store, finished goods store, distribution store, hazardous goods store, inward goods store; handling systems may include, but are not limited to, the use of – racks, pallet jacks, cartons, buckets, trolleys, pallet containers, conveyors, forklifts, fork-hoists. functions may include – receive, store and move stock, monitor stock, issue stock, dispose of obsolescent stock, despatch stock; services may include – stock enquiries, stock level maintenance, cataloguing, data entry, scanning. Systems used in the workplace for recording stock movement are outlined. Range Competenz SSB Code 101571 may include but is not limited to – electronic, paper, storage areas, movement procedures, documentation requirements. New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 5.4 21615 version 4 Page 4 of 6 Material handling equipment is identified in terms of the types of goods it may be used for. Range may include but is not limited to – conveyors, forklifts, fork-hoists, trolleys. Outcome 6 Demonstrate knowledge of board grammages, flutes, and paper types. Evidence requirements 6.1 Board grammages and flutes are identified from physical samples. Range 6.2 Liner paper types are identified from samples. Range 6.3 kraft, top kraft, recycled. Medium paper types are identified from samples. Range 6.4 board – heavy grammage, light grammage, twin cushion, single face, solid fibre; flutes – B, C, and E; solid fibre; twin cushion. recycled fibre (RF), semi-chemical (SC). Corrugator impression lines on a sample are used to differentiate between inside and outside liners. Outcome 7 Identify styles of cases and fittings. Evidence requirements 7.1 Case styles are identified from sample blanks and from finished product. Range 7.2 Fittings produced within the workplace are identified from samples. Range 7.3 RSC, HSC, 4 corner tray, lock bottom or crash lock case; die cut blank. fittings may include but are not limited to – laced sections, layers, partitions, special fittings; a minimum of two is required. The purposes of the fittings identified at 7.2 are described in terms of workplace practices. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 21615 version 4 Page 5 of 6 Outcome 8 Demonstrate knowledge of the factors contributing to production costs. Evidence requirements 8.1 Effects of wages and materials, and machinery costs are described in terms of overall production costs. 8.2 Effect of wastage is described in terms of profitability. Outcome 9 Explain the importance of confidentiality. Evidence requirements 9.1 Importance of maintaining confidentiality is explained in terms of work entrusted to the company. 9.2 Importance of maintaining confidentiality is explained in terms of the company’s clients. 9.3 Importance of maintaining confidentiality is explained in terms of the company’s business. Outcome 10 Follow written instructions and complete forms. Evidence requirements 10.1 Job instruction sheets and associated written instructions are followed to meet workplace practices. 10.2 Forms are completed in accordance with workplace practices. Range may include but is not limited to – time sheets, order forms, job bags, sign-off forms, quality check forms, computer feedback forms. Replacement information This unit standard and unit standard 23445 have been replaced by unit standard 27821. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 21615 version 4 Page 6 of 6 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 21 March 2005 31 December 2015 Rollover and Revision 2 12 December 2008 Review 3 20 September 2012 31 December 2019 Rollover 4 10 December 2015 31 December 2019 31 December 2015 Consent and Moderation Requirements (CMR) reference 0005 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016