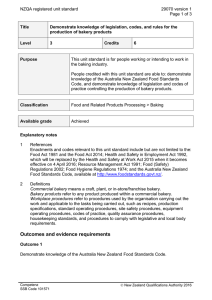

NZQA unit standard 15138 version 3

advertisement

NZQA Expiring unit standard 15138 version 3 Page 1 of 4 Title Demonstrate knowledge of bakery management systems Level 4 Credits 6 Purpose This unit standard is for people working or intending to work in a bakery. People credited with this unit standard are able to: devise time management systems for a selected bakery; develop quality management systems for a selected bakery; develop a production plan for a selected bakery; assess the methods of stock control used in a selected bakery; and develop a layout plan for a selected bakery. Classification Food and Related Products Processing > Baking Available grade Achieved Explanatory notes 1 Enactments and codes relevant to this unit standard include but are not limited to the: Food Act 1981; Health and Safety in Employment Act 1992; Food (Safety) Regulations 2002; Food Hygiene Regulations 1974; Australia New Zealand Food Standards Code available at http://www.foodstandards.govt.nz. 2 Bakery refers to a craft bakery, in-store bakery, or production plant baking facility such as a bread, biscuit, or pastry manufacturer. 3 Performance must be consistent with documented organisational policies and procedures. Outcomes and evidence requirements Outcome 1 Devise time management systems for a selected bakery. Evidence requirements 1.1 Goals for a bakery are set in accordance with the bakery’s mission. 1.2 Objectives for a bakery are set in accordance with the bakery’s goals. 1.3 Daily priorities for a bakery are set in accordance with the annual, monthly, and weekly work programme. 1.4 Situations in which time-wasting can occur are identified and minimised. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 15138 version 3 Page 2 of 4 Outcome 2 Develop quality management systems for a selected bakery. Evidence requirements 2.1 Quality management is defined as it relates to bakeries and bakery products. 2.2 Sensory evaluation tests are classified according to type and function. Range triangle, descriptive, rating, desirable product qualities, texture evaluation by bite, flavour evaluation, overall degree of liking. 2.3 Sensory evaluation tests for bakery products are described in terms of their materials and methods. 2.4 Practical uses for sensory evaluation of bakery products are outlined. 2.5 Quality management procedures for a bakery are documented and supported by a copy or written outline of organisational policy. Outcome 3 Develop a production plan for a selected bakery. Evidence requirements 3.1 Production planning is defined in relation to bakeries and bakery production schedules. 3.2 Criteria used to develop a production plan suitable for a bakery are listed and described. Range 3.3 available capacity, product range, quantities, sale dates, customer requirements, waste and stales, rework, labour, machinery, suppliers, ingredients, packaging. Production plan encompassing all of the criteria above is devised for a bakery. Outcome 4 Assess the methods of stock control used in a selected bakery. Evidence requirements 4.1 Stock control is defined and the consequences of poor stock control outlined. 4.2 Distinction between staling and spoilage is determined by identifying the causal agents. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 4.3 Types of staling and spoilage are compared in terms of the conditions which accelerate the process or encourage infection, and the effect on bakery products. Range 4.4 staling, mould, rope. Methods used to avoid staling and spoilage in a bakery are evaluated in terms of complexity, cost, and current bakery practice. Range 4.5 15138 version 3 Page 3 of 4 temperature and humidity control, cleanliness, production schedules, recipe balance, flour protein content, product moisture content, bakery construction and layout. Procedures for stock rotation in a bakery are assessed against the type of bakery, production schedules, type of ingredients, and labelling. Range labelling may include any of – stated shelf life, use-by date, bestbefore date. Outcome 5 Develop a layout plan for a selected bakery. Evidence requirements 5.1 Enactments and/or codes affecting the design of a bakery layout are identified and explained in terms of requirements that must be met. 5.2 Workflow patterns are outlined in relation to the type of bakery and product range. 5.3 Layout requirements for a bakery are determined from an analysis of the dough systems, product range, and scales of production. Range 5.4 inwards goods, ingredient storage, weigh up, wash up, mixing, proving, baking, moulding, dividing, depanning, finishing, finished product storage, retail or display, staff wash rooms, toilets, changing facilities, heating, lighting, ventilation, air conditioning, power, boilers and boiler fuel, refrigeration, compressed air systems, water systems, conveyor systems, fire exits, future expansion. Layout plan for a bakery is developed and presented as a fully labelled sketch. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 15138 version 3 Page 4 of 4 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 27 November 1998 31 December 2018 Review 2 19 May 2006 31 December 2018 Review 3 17 March 2016 31 December 2018 Consent and Moderation Requirements (CMR) reference 0111 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016