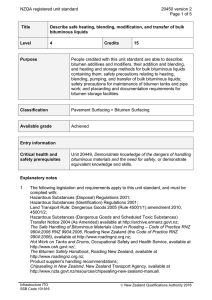

NZQA registered unit standard 28678 version 1 Page 1 of 4

advertisement

NZQA registered unit standard 28678 version 1 Page 1 of 4 Title Demonstrate knowledge of environmental protection and safety for bituminous surfacing production and application Level 4 Credits 10 Purpose People credited with this unit standard are able to demonstrate knowledge of: environmental protection and safety requirements for bituminous surfacing production and application. Classification Infrastructure Works > Generic Bituminous Surfacing Available grade Achieved Explanatory notes 1 The following legislation, codes of practice, and guidelines apply to this unit standard: Hazardous Substances (Disposal) Regulations 2001; Hazardous Substances (Identification) Regulations 2001; Land Transport Rule: Dangerous Goods 2005 (Rule 45001/1); Code of Practice for Temporary Traffic Management (CoPTTM), New Zealand Transport Agency, available at http://www.nzta.govt.nz/resources/code-temp-trafficmanagement/index.html RNZ 9904, The Safe Handling of Bituminous Materials Used in Roading – Code of Practice RNZ 9904:2006, Roading New Zealand, available for purchase at http://www.nzcontractors.co.nz/; AS 2865:2009 Confined Spaces, available at http://www.business.govt.nz; The Bitumen Safety Handbook, Roading New Zealand, available for purchase at http://www.nzcontractors.org.nz; Roading New Zealand Emergency Procedure Guide – Transport Card, Roading New Zealand, available on request at http://www.nzcontractors.org.nz; Hot Work on Tanks and Drums, Department of Labour, available at http://www.business.govt.nz/worksafe/. Local authority requirements for disposal of hazardous substances; Product supplier’s handling recommendations; Site safety plan for bituminous surfacing site. 2 Definitions Company procedures refers to all documented policies, procedures, and methodologies of the candidate’s employer at the time of training, including but not limited to those relating to health, safety, environment, quality, and operations. PPE means personal protective equipment. SDS means Safety Data Sheets as provided by the product manufacturer. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 28678 version 1 Page 2 of 4 Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of environmental protection for bituminous surfacing production and application. Evidence requirements 1.1 Materials used in the bituminous surfacing industry are identified and described in terms of their potential impacts on the environment. Range 1.2 Methods for protecting the environment from runoff are described in accordance with company procedures. Range 1.3 environment at a bituminous production plant and a surfacing site. Emergency procedures for runoff and spill incidents involving bituminous materials are explained in accordance with RNZ 9904:2006 and company procedures. Range 1.5 examples of methods – weather watch, planning, covering catchpits and sumps, programming high-risk areas for low-risk times. Methods for protecting the environment from noise and air pollution are described in accordance with RNZ 9904:2006 and company procedures. Range 1.4 materials – hot binder, emulsified binder, kerosene, diesel, chemical additives. spillage clean up, waterway protection, containment, notification. Safe disposal of bituminous surfacing products is described in accordance with local authority requirements and company procedures. Range consents, permits, approved sites. Outcome 2 Demonstrate knowledge of safety requirements for bituminous surfacing production and application. Evidence requirements 2.1 Hazards associated with hot bituminous liquids are described in accordance with The Bitumen Safety Handbook. Range Infrastructure ITO SSB Code 101813 includes but is not limited to – burns, fire, fumes, explosion, water contamination, spills, impact of cutbacks. New Zealand Qualifications Authority 2016 NZQA registered unit standard 2.2 Hazards of bituminous surfacing plant and equipment are described in accordance with The Bitumen Safety Handbook. Range 2.3 operations at – production plant, surfacing site. Safety precautions for maintaining, heating, blending, pumping, and transferring bituminous products are described in accordance with The Bitumen Safety Handbook, RNZ 9004:2006, Hot Work on Tanks and Drums ,company procedures, and SDS. Range 2.7 hazards – steam, fire, hot oil, confined space, working at height, handling chemical additives, mechanical plant, moving plant, hotwork, remote marking; controls include but are not limited to fire-fighting equipment for production plants and mobile plant, PPE. Safety precautions for protecting the public from bituminous surfacing operations are described in accordance with The Bitumen Safety Handbook, CoPTTM, and a site safety plan. Range 2.6 purpose, content, supplier’s obligation to provide, availability. Control of bituminous surfacing hazards during production and construction is described in accordance with The Bitumen Safety Handbook, RNZ 9004:2006, company procedures, and SDS. Range 2.5 includes but is not limited to – hot surfaces, hoses, hose couplings, blockages, pressure expansion, pumping pressure, steam explosion, ignition source, hydraulics, heating equipment, rotating equipment, height, electricity, air pressure, deficient maintenance. SDS for bituminous surfacings products are described in accordance with RNZ 9004:2006. Range 2.4 28678 version 1 Page 3 of 4 PPE, tanks, pipelines, pumps, valves, confined space entry. Requirements for placarding and tracking tank contents for bituminous materials are described in accordance with Regulations, and Section 7 of Rule 45001/1. Range materials – emulsion, hot bitumen, cutback bitumen, elevated temperature binders. 2.8 Emergency procedures for incidents involving bituminous products are described in accordance with company procedures and/or the Roading New Zealand Emergency Procedure Guide. 2.9 First aid procedures for bitumen burns are described in accordance with the Bitumen Burns Card and The Bitumen Safety Handbook. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 2.10 28678 version 1 Page 4 of 4 First aid procedures for inhalation, ingestion, and skin absorption of bituminous products, adhesion agents, and additives are described in accordance with SDS. evidence is required of – at least one bituminous product, diesel, kerosene, one adhesion agent. Range Planned review date 31 December 2019 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 19 February 2015 N/A Consent and Moderation Requirements (CMR) reference 0101 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMRs). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Infrastructure ITO qualifications@infrastructureito.org.nz if you wish to suggest changes to the content of this unit standard. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016