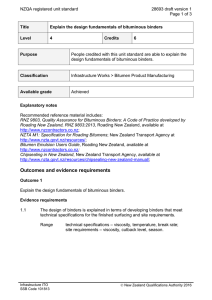

NZQA registered unit standard 28694 version 1 Page 1 of 4

advertisement

NZQA registered unit standard 28694 version 1 Page 1 of 4 Title Produce binders at a bituminous binder plant Level 4 Credits 22 Purpose People credited with this unit standard are able to, at a bituminous binder plant: prepare for production of binders; produce binders for pavement surfacing; and manage environmental protection and plant maintenance. Classification Infrastructure Works > Bitumen Product Manufacturing Available grade Achieved Explanatory notes 1 The following codes of practice, standards, and specifications apply to this unit standard and must be complied with RNZ 9803, Quality Assurance for Bituminous Binders: A Code of Practice developed by Roading New Zealand, RNZ 9803:2013, Roading New Zealand, available at http://www.roadingnz.org.nz/sites/roadingnz.org.nz/files/RNZ9803_0513_Final.pdf; Bitumen Emulsion Users Guide, Roading New Zealand, at http://www.roadingnz.org.nz/sites/roadingnz.org.nz/files/Bitumen_Emulsion_Users_G uide--Final.pdf; NZTA M1: Specification for Roading Bitumens; New Zealand Transport Agency at http://www.nzta.govt.nz/resources/; Contract quality plans. 2 Assessment against this unit standard must be based on evidence from working at a bituminous binder plant. 3 Competence in this unit standard requires compliance with a bituminous binder plant operating manual. 4 Definitions Company procedures refers to all documented policies, procedures, and methodologies of the candidate’s employer at the time of training, including but not limited to those relating to health, safety, environment, quality, and operations. Operating manuals refers to the plant operating manual and manuals written for specific components or items of plant and equipment that may be published by the manufacturer or the company. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard 28694 version 1 Page 2 of 4 Outcomes and evidence requirements Outcome 1 Prepare for production of binders at a bituminous binder plant. Range one each of – hot bitumen, cut back binder, emulsified binder, polymer modified binder. Evidence requirements 1.1 Company technical data sheets are checked for material requirements in accordance with company procedures. Range 1.2 Materials to match binder recipe are purchased in accordance with company procedures. Range 1.3 materials – bitumen grade, additives, targets, tolerances. check recipe, check types of binder, quality, and quantities of materials in stock; order additional materials. Sampling and testing plan is developed to ensure that requirements of RNZ 9803:2013 and contract quality plans will be met. Range requirements for – binder, finished product. 1.4 Scheduling of production time and load-out is determined in accordance with customer delivery requirements. 1.5 A piece of manufacturing plant is calibrated to consistently produce a uniform binder within the specified tolerances. Range may include – flow meter. Outcome 2 Produce binders for pavement surfacing at a bituminous binder plant. Range one each of – hot bitumen, cut back, emulsion, polymer modified. Evidence requirements 2.1 Bituminous binder plant is operated in accordance with operating manuals. 2.2 Production process is monitored to ensure binder conforms to specifications, and any required actions to maintain tolerances are taken and recorded in accordance with company procedures. Range Infrastructure ITO SSB Code 101813 tolerances may include but are not limited to – temperature, pressures, flow rates, production rate, pH, proportions. New Zealand Qualifications Authority 2016 NZQA registered unit standard 2.3 All operations are safely completed and workplace and equipment are cleaned in accordance with operating manuals and company procedures. Range 2.4 stirring, heating; examples of deterioration – polymer agglomeration, emulsion settlement. Materials and product sampling and testing are carried out and documented in accordance with the sampling and testing plan. Range 2.6 operations – inventory, start-up, shut-down, load-out. Binders are handled and stored to avoid product deterioration in accordance with operating manuals and technical data sheets. Range 2.5 28694 version 1 Page 3 of 4 base bitumen, emulsion, polymer, finished binder. Binder product meets target properties specified in contract quality plan. Range evidence is required of – understanding test results, conformance, non-conformance, corrective action. 2.7 All binder documentation is completed in accordance with customer requirements, specifications, contract quality plans, and company procedures. 2.8 Binder is loaded in accordance with operating manual and company procedures, and documentation is completed in accordance with legislation. Range tank space and contents must be checked prior to load-out. Outcome 3 Manage environmental protection and plant maintenance at a bituminous binder plant. Evidence requirements 3.1 Consents for the plant are accessed to confirm requirements for environmental protection in accordance with company procedures. 3.2 Environmental protection is planned and emissions are controlled in accordance with consent requirements and operating manuals. Range emissions – noise, dust, odour, fumes, steam, run-off. 3.3 Scheduled downtime and maintenance programmes are allowed for and monitored in relation to production planning. 3.4 Routine maintenance is carried out in accordance with operating manuals, and specialist maintenance is reported and documented in accordance with company procedures. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016 NZQA registered unit standard Planned review date 28694 version 1 Page 4 of 4 31 December 2019 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 19 February 2015 N/A Consent and Moderation Requirements (CMR) reference 0101 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMRs). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Infrastructure ITO qualifications@infrastructureito.org.nz if you wish to suggest changes to the content of this unit standard. Infrastructure ITO SSB Code 101813 New Zealand Qualifications Authority 2016