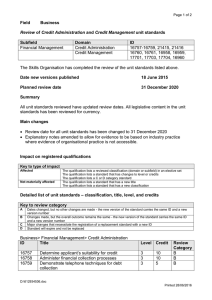

Qualification details

advertisement

Qualification details Title New Zealand Certificate in Glass Container Manufacturing (Level 4) with strands in Advanced Forming Operations, Advanced Finished Product Operations, and Advanced Batch and Furnace Operations Version 2 Qualification type Certificate Level 4 Credits 100 – 140 NZSCED 030199 Engineering and Related Technologies > Manufacturing, Engineering and Technology > Manufacturing Engineering and Technology not elsewhere classified Qualification developer Competenz Next review December 2019 Approval date January 2016 Strategic purpose statement The purpose of this qualification is to provide the glass container manufacturing sector with people who are able to manage and monitor workplace safety, quality and productivity in the glass container manufacturing sector. This qualification is stranded in order to recognise the specific skills and knowledge required to work as senior operators, waremakers and team leaders in controlling and optimising glass container manufacturing equipment and processes in the following functions: Advanced Forming Operations Advanced Finished Products Operations Advanced Batch and Furnace Operations. Graduates will be capable of self-management of learning and performance under broad guidance, and will have some responsibility for performance of others. Outcome Statement Graduate profile Qualification Reference 2445 © New Zealand Qualifications Authority 2016 Graduates of this qualification will, in accordance with organisational procedures, be able to: Critically analyse and monitor production data and performance in order to implement process improvements and manage individual and team outputs to meet production requirements Diagnose, monitor and resolve routine and critical operational issues to maintain product output and specifications. Graduates of the Advanced Forming Operations Strand will also version 2 Page 1 of 5 be able to: Set up, monitor and adjust forming machinery and equipment to optimise glass container forming production. Graduates of the Advanced Finished Product Operations Strand will also be able to: Oversee and optimise preparation of manufactured glass containers for dispatch, manage job change requirements, and carry out quality assurance and inspection processes. Graduates of the Advanced Batch and Furnace Operations Strand will also be able to: Analyse and monitor glass container raw materials and make necessary adjustments in order to optimise furnace operation and efficiency Operate a furnace to manufacture glass containers, and carry out emergency operation of plant services. Education pathway On completion of this qualification graduates may also progress to further training in staff or business management, manufacturing processes or competitive manufacturing. Employment pathway People completing this qualification will be able to work as glass container manufacturing senior operators, waremakers and team leaders. Qualification specifications Qualification award This qualification can be awarded by an organisation which has an approved programme of study or industry training programme leading to the qualification. The certificate will display the logo of the NZQF and may display the name and/or logo of the awarding body. Evidence requirements for assuring consistency All TEOs either arranging training or delivering programmes that lead to the award of the qualification are required to participate in a consistency process scheduled by NZQA. This will involve reviewing evidence associated with graduate’s achievement of outcomes, and agreeing acceptable thresholds for qualification outcome achievement and areas for improvement. To demonstrate how graduates are achieving the qualification graduate profile outcomes, TEOs are required to produce their own evidence in a high level report. Evidence will include the following: Qualification Reference 2445 © New Zealand Qualifications Authority 2016 Employer surveys to determine if graduates of the qualification meet the graduate profile outcomes version 2 Page 2 of 5 Evidence of effective processes to ensure programmes continue to meet current industry needs A range of workplace evidence demonstrating that graduates meet the graduate profile outcomes Any other relevant evidence as appropriate. Further information about the managing consistency process can be found on the NZQA website. Minimum standard of achievement and standards for grade endorsements Achievement of all outcomes. There are no grade endorsements for this qualification. Other requirements for the qualification (including regulatory body or legislative requirements) There are no mandatory prerequisites for this qualification. General conditions for the programme leading to the qualification General conditions for programme N/A Conditions relating to the Graduate profile Qualification outcomes Conditions 1 Learning and assessment should include: Critically analyse and monitor production data and performance in order to implement process improvements and manage individual and team outputs to meet production requirements 30 credits 2 Applying knowledge of shift production quality specifications, competitive manufacturing processes and plant efficiency targets to workload requirements Analysing production data and communicating information to individuals or teams Carrying out process improvements, and evaluating their ongoing effectiveness Workplace health and safety procedures, hazard identification, and occupational health and safety incident investigations Coaching staff members where required in technical skills needed to carry out job Applying knowledge of methods to control and minimise glass container manufacturing waste and rework Diagnose, monitor and resolve routine and critical operational issues to maintain product output and specifications Learning and assessment should include: Methods to diagnose routine and critical operational issues such as root cause analysis, and identifying upstream and downstream impact of these issues 10 credits Resolving routine and critical operational issues to maintain quality standards, production output and plant efficiency targets Qualification Reference 2445 © New Zealand Qualifications Authority 2016 version 2 Page 3 of 5 3 Advanced Forming Operations Strand Applying knowledge of independent section machine and settings, gob forming, forehearth and feeder operation to control and optimise forming operations Monitoring production on all lines and making adjustments to meet job specifications and quality requirements 100 credits Preparing for, and managing forming job change requirements Advanced Finished Product Operations Strand Learning and assessment should include: Oversee and optimise preparation of manufactured glass containers for dispatch, manage job change requirements, and carry out quality assurance and inspection processes 80 credits 5 Optimising packaging process based on data collected in order to meet quality requirements Preparing samples to test inspection requirements Confirming food safety requirements have been met and relevant documentation completed prior to dispatch Preparing for, and managing finished product job change requirements Carrying out quality inspections of finished products Applying knowledge of driver, verifier, auditor and operator processes, annealing and grading; capacity changes for new products Advanced Batch and Furnace Operations Strand Learning and assessment should include: Monitoring raw material batch integrity Analyse and monitor glass container raw materials and make necessary adjustments in order to optimise furnace operation and efficiency Interpreting laboratory data to ensure glass composition and batch integrity is maintained Making recommendations for batch make up in response to production and quality requirements Monitoring batch pattern 10 credits 6 Learning and assessment should include: Set up, monitor and adjust forming machinery and equipment to optimise glass container forming production 4 Monitoring process improvements to ensure ongoing compliance Operate a furnace to manufacture glass containers, and carry out emergency operation of plant services 50 credits Learning and assessment should include: Responding to furnace alarms and carrying out repairs and adjustments as identified by staff members Optimising furnace operation based on visual and data checks Applying knowledge of compressors to furnace operations Carrying out emergency operation of plant services Transition information Replacement information Qualification Reference 2445 © New Zealand Qualifications Authority 2016 This qualification replaced the National Certificate in Glass Container Manufacturing (Level 4) [Ref: 1462]. version 2 Page 4 of 5 The last date for entry into programmes leading to the replaced qualification is 31 December 2016.The last date for assessment against the replaced qualification is 31 December 2017. People currently working towards the replaced qualification must complete their requirements, or transfer to a programme of study or training leading to the replacement qualification, by 31 December 2017. It is anticipated that no existing candidates will be disadvantaged by these transition arrangements. However, anyone who feels that they have been disadvantaged may appeal to Competenz at the address below. Appeals will be considered on a case by case basis. Competenz, PO Box 9005, Newmarket, Auckland 1149. Publication information Version 2 of this qualification was published in January 2016 to: set the last date of entry into programmes leading to the replaced qualifications as 31 December 2016 extend the last date of assessment on the replaced qualification from 31 December 2016 to 31 December 2017 Update GPO statements 3 and 6. Qualification Reference 2445 © New Zealand Qualifications Authority 2016 version 2 Page 5 of 5