NZQA unit standard 5756 version 5

advertisement

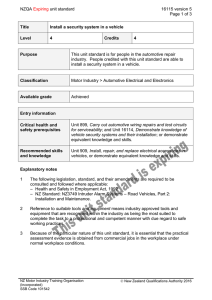

NZQA Expiring unit standard 5756 version 5 Page 1 of 4 Title Book in work, interpret a job sheet, and inspect and identify vehicle damage Level 3 Credits 3 Purpose This unit standard is for people who work in the motor industry. Those credited with this unit standard are able to: book in work; demonstrate knowledge of vehicle body damage; interpret a job sheet and inspect the damaged vehicle. Classification Motor Industry > Panelbeating Available grade Achieved Explanatory notes 1 The following legislation and regulations (and subsequent amendments) are relevant to this unit standard and must be followed where applicable: – Health and Safety in Employment Act, 1992; – Transport (Vehicle Standards) Regulations, 1990 and Guide to Vehicle Standards (MOT Guides 1 and 2), (available from Standards New Zealand, telephone 04 498 5991). 2 When the evidence requirements state 'company guidelines', it is assumed that it is to the same standard as the product and vehicle manufacturers' standards. 3 Because of the particular nature of this unit standard it is essential that assessment be carried out in a commercial workplace under normal working conditions. Outcomes and evidence requirements Outcome 1 Book in work. Evidence requirements 1.1 Customer is greeted courteously according to company guidelines. 1.2 Customer and vehicle details are obtained and recorded. Range may include but are not limited to – name, address, phone number, engine, chassis, model numbers, vehicle identification number (VIN), work required, odometer, insurance details, accident details. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 1.3 5756 version 5 Page 2 of 4 Recorded information is passed on to supervisor according to company guidelines. Outcome 2 Identify vehicle body damage. Evidence requirements 2.1 Vehicle body type is identified according to vehicle manufacturer's specifications. Range 2.2 Panels that make up the body structures are identified according to vehicle manufacturer's specifications. Range 2.3 suspension system, steering, engine, power train, rear axle, braking, radiators, air conditioning. Impact effects on vehicle safety systems compared to original manufacture's specifications are identified. Range 2.6 unibody, frame and/or truck chassis. Impact effects on mechanical parts compared to original manufacture's specifications are identified. Range 2.5 front structure, main body, rear structure. Impact effects on a vehicle compared to original manufacturer's specifications are identified. Range 2.4 unibody, separate frame type, chassis. brake systems, steering system, restraints, air bags. Vehicle identification plate and code numbers are identified to enable replacement parts to be procured as specified by vehicle manufacturer's specifications and according to company guidelines. Outcome 3 Interpret job sheet and inspect the damaged vehicle. Evidence requirements 3.1 Job sheet is interpreted according to company policy and all damage is noted. 3.2 Vehicle details are obtained to enable parts and materials to be ordered. Range engine, chassis, model numbers, vehicle identification number (VIN), lens numbers. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 3.3 5756 version 5 Page 3 of 4 Safe working practices are carried out throughout the task. Range personal safety; safety of other people; vehicle safety; workshop safety; environmental safety; tool, equipment, and machine safety. 3.4 Hidden damage is identified and noted according to the vehicle manufacturer's specifications. 3.5 Conditions and area of impact are identified and noted. Range 3.6 Misaligned and damaged mechanical parts are identified and noted according to manufacturer's specifications. Range 3.7 side, full frontal, rear end, angle, impact force. may include but are not limited to – steering, suspension, power train, rear axle and wheels, engine and components, radiator and cooling system, air conditioning components, sway bar, LPG and CNG cylinders and fittings, fuel tank and fittings, braking systems, exhaust system. Misaligned and damaged structural and body panels are identified and noted according to manufacturer's specifications. Range may include but are not limited to – bonnet, guards, doors, quarter panels, front and rear panels, bootlid, inner guard panels, firewall, wheel arches, roof, under body, pillars, sill panels, radiator panel, hinges. 3.8 Misaligned rails and cross members are identified and noted according to manufacturer's specifications. 3.9 Damaged electrical components and wiring are identified and noted to enable them to be replaced and/or repaired according to manufacturer's specifications. 3.10 Impact damage on other body panels and parts is identified and noted to enable the panels and parts to be replaced and/or repaired according to manufacturer's specifications and legislation. 3.11 Damaged parts are identified and noted to enable them to be replaced and/or repaired according to manufacturer's specifications and legislation. Range bumpers, mouldings, badges, grille, bezels, interior trim and fittings, seat belts, air bags, glass, lights. Replacement information NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 This unit standard has been replaced by unit standard 23982. New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 5756 version 5 Page 4 of 4 This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 29 January 1996 31 December 2016 Review 2 20 December 1998 31 December 2016 Revision 3 16 October 2003 31 December 2016 Review 4 26 November 2007 31 December 2016 Rollover 5 19 November 2010 31 December 2016 Accreditation and Moderation Action Plan (AMAP) reference 0014 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Consent requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. NZ Motor Industry Training Organisation (Incorporated) SSB Code 101542 New Zealand Qualifications Authority 2016