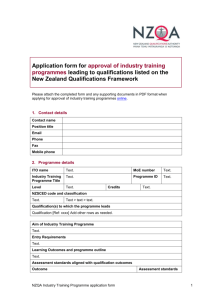

Qualification details

advertisement

Qualification details Title New Zealand Certificate in Engineering Fabrication (Trade) (Level 4) with strands in Heavy Fabrication, Light Fabrication, and Steel Construction Version 1 Qualification type Certificate Level 4 Credits 255-270 credits NZSCED 030711 Engineering and Related Technologies > Mechanical and Industrial Engineering and Technology > Boiler-making and Welding Qualification developer Competenz Next review July 2020 Approval date July 2015 Strategic purpose statement The purpose of this qualification is to provide the engineering fabrication industry with skilled tradespeople who are able to safely and independently perform fabrication tasks within their chosen discipline, to industry standards. This qualification is designed for people working in the industry and will typically be achieved in a workplace environment whilst completing a New Zealand Apprenticeship. Graduate profile Graduates of this qualification will be able to: - Outcome Statement - - - - - Qualification Reference 2719 © New Zealand Qualifications Authority 2015 Apply an understanding of the relevant Health and Safety legislation and workplace safety culture in order to work safely and meet responsibilities in a commercial engineering fabrication environment Interpret drawings and/or specifications and select and use the appropriate fabrication materials, processes, tools, and equipment for the fabrication task being undertaken Apply relevant knowledge of fabrication principles and practices, and problem solving skills, to perform engineering fabrication tasks to industry standards Apply knowledge of welding to safely weld to an appropriate industry standard in a commercial engineering fabrication environment Apply an understanding of effective and efficient processes and principles, and quality systems to the fabrication of components, and/or provision of services in a commercial engineering fabrication environment Practice effective communication within an engineering fabrication team and the wider workplace Recognise the limits of own ability and the importance of working with integrity and maintaining currency in the engineering fabrication field Page 1 of 7 Graduates of the Heavy Fabrication strand will also be able to: - Produce a range of heavy fabricated products, including trucks and trailers, earthmoving machinery, manufacturing equipment, and pressure vessels from heavy gauge plate, sections, and pipes using the appropriate tools and current relevant techniques Graduates of the Light Fabrication strand will also be able to: - Produce a range of light fabricated products such as ducting, architectural fixtures, and balustrading from light gauge sheet, sections and pipes using the appropriate tools and current relevant techniques Graduates of the Steel Construction strand will also be able to: - Education pathway Produce and install a range of structural steel elements for building and civil engineering projects, using the appropriate tools and current relevant techniques This qualification builds on the National Certificate in Mechanical Engineering (Level 2) [Ref: 1220] or the New Zealand Certificate in Mechanical Engineering (Level 3) [Ref: 2715]. Graduates of these qualifications will have credits towards this qualification. This qualification can lead to the New Zealand Certificate in Mechanical Engineering (Advanced) (Level 5) [Ref: 2716]. Graduates intending to become Certified Engineering Technicians should complete the New Zealand Diploma in Engineering Practice (with strands in Civil Engineering, Electrical Engineering and Mechanical Engineering) (Level 6) [Ref: 1714]. Employment pathway Graduates of this qualification will be able to work independently as Engineering Fabrication tradespeople in their chosen discipline, in a broad range of sectors within the fabrication or construction industries. Specific roles for each of the strands may include: - - Heavy Fabrication strand - Process Plant Fabricator, Fabricator for pressure equipment, heavy transport equipment, or machinery, etc Light Fabrication strand - Sheet Metal Worker, Process Plant Fabricator Steel Construction strand - Structural steelworker for buildings, bridges and cranes, etc. Qualification specifications Qualification award This qualification can be awarded by an organisation which has an approved programme of study or industry training programme leading to the qualification. The certificate will display the logo of the NZQF and may display the name and/or logo of the awarding body. Qualification Reference 2719 © New Zealand Qualifications Authority 2015 Page 2 of 7 Evidence requirements for assuring consistency All TEOs either arranging training or delivering programmes that lead to the award of the qualification are required to participate in a consistency process scheduled by NZQA. This will involve reviewing evidence associated with graduates’ achievement of outcomes, and agreeing acceptable thresholds for qualification outcome achievement and areas for improvement. To demonstrate how graduates are achieving the qualification graduate profile outcomes, TEOs are required to produce their own evidence in a high level report. Evidence will include the following: - Employer surveys to determine if graduates of the qualification meet the graduate profile outcomes Evidence of effective processes to ensure programmes continue to meet current industry needs A range of workplace evidence demonstrating that graduates meet the graduate profile outcomes Any other relevant evidence as appropriate Further information about the managing consistency process can be found on the NZQA website. Minimum standard of achievement and standards for grade endorsements Achievement of all outcomes is required. Other requirements for the qualification (including regulatory body or legislative requirements) It is recommended that people enrolling in a programme leading to this qualification will hold the National Certificate in Education Achievement (NCEA) Level 2 [Ref: 0973] or equivalent. There are no grade endorsements for this qualification. General conditions for the programme leading to the qualification General conditions for programme It is expected that fundamental health and safety awareness will be a focus at the start of the programme, and further embedded in all onjob and off-job learning throughout the duration of the programme. This qualification will typically be achieved in a commercial environment whilst completing a New Zealand Apprenticeship. It is expected that the learning of technical knowledge and skills will be reinforced through application in a commercial environment. Should unit standards be specified in a programme of study or industry training programme leading to this qualification, please consult the explanatory notes section of the unit standards concerned, as there may be legislative and health and safety requirements. Qualification Reference 2719 © New Zealand Qualifications Authority 2015 Page 3 of 7 Conditions relating to the Graduate profile Qualification outcomes Conditions 1 Programmes must include coverage of the following topics (as a minimum): Apply an understanding of the relevant Health and Safety legislation and workplace safety culture in order to work safely and meet responsibilities in a commercial engineering fabrication environment Credits 15 2 Interpret drawings and/or specifications and select and use the appropriate fabrication materials, processes, tools, and equipment for the task being undertaken Credits 55 - Understanding of own responsibilities in the workplace under relevant current Acts and Regulations Understanding of machine guarding principles and requirements Working safely and contributing to a safe environment Hazard identification, assessment and control, machine isolation, reporting, audit and Personal Protective Equipment (PPE) requirements Programmes must include coverage of the following topics (as a minimum): - Production and interpretation of engineering sketches - Production and interpretation of simple component drawings - Knowledge of calculations and units of measurement for engineering fabrication - Job planning – process analysis, sequence, risk assessment, job costing, material optimisation - Knowledge of the composition and characteristics of fabrication materials - Knowledge of available and appropriate processes, tools and equipment to suit material, plan, etc. Programmes may also include: 3 Apply relevant knowledge of fabrication principles and practices, and problem solving skills, to perform engineering fabrication tasks to industry standards Credits 65 - Use of Computer Aided Design CAD for modelling - Knowledge of Computer Numerical Control (CNC) concepts and applications Programmes must include coverage of the following topics (as a minimum): - Qualification Reference 2719 © New Zealand Qualifications Authority 2015 Develop fabrication patterns for simple three-dimensional objects Transition knowledge Application of calculations and measurement Mistake proofing, process analysis, and sequencing Forming, shaping, and distortion control Cutting of materials using mechanical or thermal equipment, including manual and mechanised processes Damage minimisation Selection and inspection of simple lifting appliances, slinging and securing loads, and carrying out lifting Page 4 of 7 - procedures Carrying out work efficiently and according to specifications Programmes may also include interpretation of relevant standards such as codes of practice, Australian/New Zealand standards in welding. 4 Apply knowledge of welding to safely weld to an appropriate industry standard in a commercial engineering fabrication environment Programmes must include coverage of the following topics (as a minimum): Credits 30 - - 5 Apply an understanding of effective and efficient processes and principles, and quality systems to the fabrication of components and/or provision of services in a commercial engineering fabrication environment Credits 10 6 Practice effective communication within an engineering fabrication team and the wider workplace Credits 10 Knowledge of gas metal arc welding (GMAW), manual metal arc welding (MMAW), gas tungsten arc welding (GTAW) and flux cored arc welding (FCAW) Welding steel and steel structures and other metals to a general purpose industry standard using the relevant welding process and positions (note: positions must include downhand, as a minimum) Distortion control Programmes must include coverage of the following topics (as a minimum): - Awareness of different models, e.g. lean manufacturing Identifying and eliminating wasteful processes Applying the concepts of continuous improvement Quality control Process planning Delivering in full, on time, and to specifications Programmes must include coverage of the following topics (as a minimum): - - Confirming and clarifying instructions Understanding the importance of, and completing, workplace documentation Communicating with teammates, customers, supervisors, other management (including awareness of other cultures and languages in the workplace) Communicating health and safety matters Programmes may also include the mentoring of apprentices, peers, etc. 7 Recognise the limits of own ability and the importance of working with integrity and maintaining currency in the engineering fabrication field Credits 5 Qualification Reference 2719 © New Zealand Qualifications Authority 2015 Programmes must include coverage of the following topics (as a minimum): - Working to an accepted industry standard for a tradesperson Seeking advice or guidance when required Overview and understanding of alternative manufacturing and engineering processes Page 5 of 7 Programmes may also include: - Heavy Fabrication strand Produce a range of heavy fabricated products, including trucks and trailers, earthmoving machinery, manufacturing equipment, and pressure vessels from heavy gauge plate, sections, and pipes using the appropriate tools and current relevant techniques Continual/lifelong learning and knowledge acquisition Researching new technology, processes, practices, equipment Programmes must include coverage of the following topics (as a minimum): - Specific welding processes and positions The manufacturing process, including use of the equipment required to handle heavy materials Credits 80 Light Fabrication strand Produce a range of light fabricated products such as ducting, architectural fixtures, and balustrading from light gauge sheet, sections, and pipes using the appropriate tools and current relevant techniques Programmes must include coverage of the following topics (as a minimum): - Specific welding processes and positions The manufacturing process, including use of the equipment required to handle light materials Finishing skills Credits 80 Steel Construction strand Produce and install a range of structural steel elements for building and civil engineering projects, using the appropriate tools and current relevant techniques Credits 65 Qualification Reference 2719 © New Zealand Qualifications Authority 2015 Programmes must include coverage of the following topics (as a minimum): - Specific welding processes and positions The manufacturing process, including use of the equipment required to handle structural materials Use of elevated work platforms, mobile scaffolds, rigging equipment Site installation Page 6 of 7 Transition information Replacement information This qualification replaced the: - - National Certificate in Engineering - Fabrication (Level 4) with strands in Heavy Fabrication, Light Fabrication, and Steel Construction [Ref: 0122] National Certificate in Welding (Level 4) [Ref: 1616] The last date for entry into the replaced qualifications is 31 December 2017. The last date for assessments to take place for the replaced qualifications is 31 December 2021. It is anticipated that no existing candidates will be disadvantaged by these transition arrangements. However, anyone who feels that they have been disadvantaged may appeal to Competenz at the address below. Appeals will be considered on a case by case basis. Competenz PO Box 9005 Newmarket Auckland 1149 Telephone 0800 526 1800 Email info@competenz.org.nz Website www.competenz.org.nz. Republication information Version 1 of this qualification was republished in May 2016 to extend the last date of enrolment into programmes leading to the National Certificate in Welding (Level 4) [Ref: 1616] from 31 December 2016 to 31 December 2017. Qualification Reference 2719 © New Zealand Qualifications Authority 2015 Page 7 of 7