RIGGING Interpret and apply the Health and industry activities

advertisement

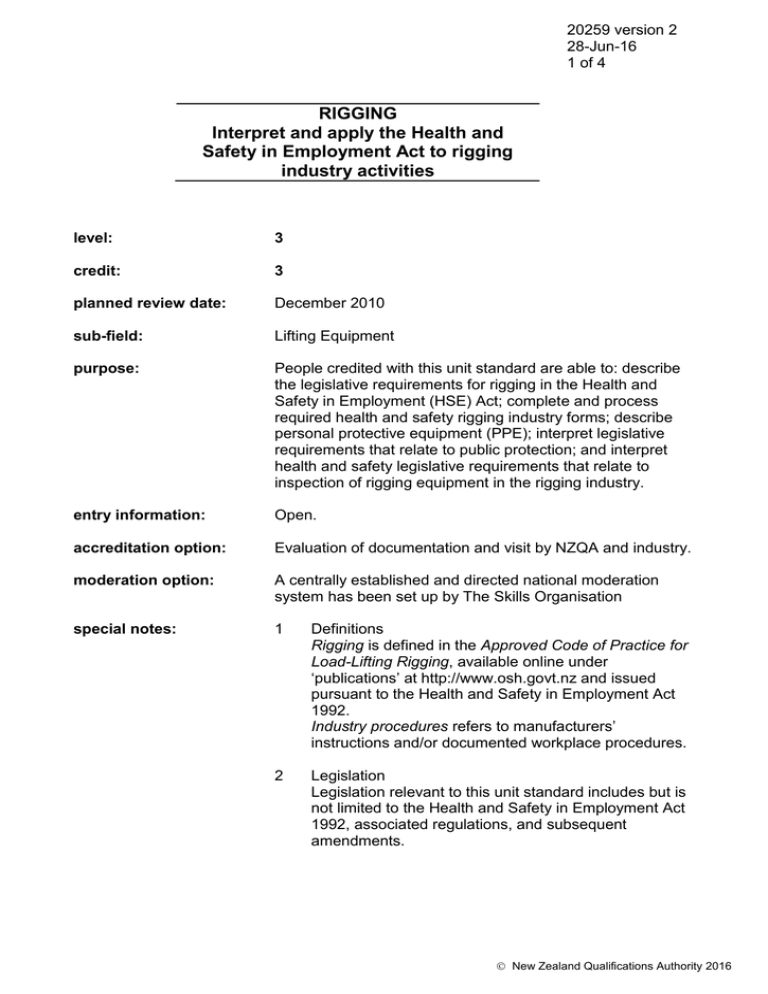

20259 version 2 28-Jun-16 1 of 4 RIGGING Interpret and apply the Health and Safety in Employment Act to rigging industry activities level: 3 credit: 3 planned review date: December 2010 sub-field: Lifting Equipment purpose: People credited with this unit standard are able to: describe the legislative requirements for rigging in the Health and Safety in Employment (HSE) Act; complete and process required health and safety rigging industry forms; describe personal protective equipment (PPE); interpret legislative requirements that relate to public protection; and interpret health and safety legislative requirements that relate to inspection of rigging equipment in the rigging industry. entry information: Open. accreditation option: Evaluation of documentation and visit by NZQA and industry. moderation option: A centrally established and directed national moderation system has been set up by The Skills Organisation special notes: 1 Definitions Rigging is defined in the Approved Code of Practice for Load-Lifting Rigging, available online under ‘publications’ at http://www.osh.govt.nz and issued pursuant to the Health and Safety in Employment Act 1992. Industry procedures refers to manufacturers’ instructions and/or documented workplace procedures. 2 Legislation Legislation relevant to this unit standard includes but is not limited to the Health and Safety in Employment Act 1992, associated regulations, and subsequent amendments. New Zealand Qualifications Authority 2016 20259 version 2 28-Jun-16 2 of 4 RIGGING Interpret and apply the Health and Safety in Employment Act to rigging industry activities Elements and Performance Criteria element 1 Describe the legislative requirements for rigging in the HSE Act. performance criteria 1.1 Description identifies responsibilities of employers and employees in the rigging industry under the Act. 1.2 Description identifies and explains hazard management procedures for rigging in terms of hazard identification sheets and proximity to power lines. 1.3 Description identifies and explains training and competency requirements for rigging. element 2 Complete and process required health and safety rigging industry forms. Range: notifications, inspections, registers. performance criteria 2.1 Rigging industry health and safety notification forms are completed and processed as required in accordance with industry procedures. 2.2 Rigging industry health and safety inspection documentation is completed and processed as required in accordance with industry procedures. 2.3 Rigging industry health and safety registers are completed and processed as required in accordance with industry procedures. element 3 Describe personal protective equipment (PPE) in the rigging industry. Range: PPE includes but is not limited to – hard-hats, footwear, clothing, eye protection, safety (static) lines, belts, harnesses. New Zealand Qualifications Authority 2016 20259 version 2 28-Jun-16 3 of 4 RIGGING Interpret and apply the Health and Safety in Employment Act to rigging industry activities performance criteria 3.1 Description identifies PPE to be carried by riggers in industry. 3.2 Description explains use of PPE in the rigging industry. 3.3 Description explains maintenance and inspection of PPE in the rigging industry. element 4 Interpret legislative requirements that relate to public protection in the rigging industry. performance criteria 4.1 The legislative requirements for lifting equipment are interpreted in terms of their relevance to health and safety in the rigging industry. 4.2 The legislative requirements for load lifting are interpreted in terms of their relevance to health and safety in the rigging industry. 4.3 The legislative requirements for safety nets are interpreted in terms of their relevance to health and safety in the rigging industry. element 5 Interpret health and safety legislative requirements that relate to inspection of rigging equipment. performance criteria 5.1 Equipment inspection requirements are interpreted in terms of their relevance to health and safety in the rigging industry. Comments on this unit standard Please contact The Skills Organisation at reviewcomments@skills.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016 20259 version 2 28-Jun-16 4 of 4 RIGGING Interpret and apply the Health and Safety in Employment Act to rigging industry activities Please Note Providers must be accredited by the Qualifications Authority or a delegated interinstitutional body before they can register credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by the Qualifications Authority before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for providers wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. This unit standard is covered by AMAP 0183 http://www.nzqa.govt.nz/site/framework/search.html. which can be accessed at New Zealand Qualifications Authority 2016