Prepare chemicals for batch production in a petrochemical workplace

advertisement

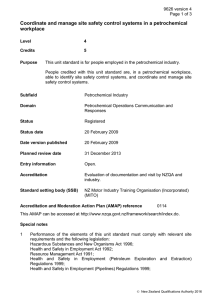

9607 version 4 Page 1 of 4 Prepare chemicals for batch production in a petrochemical workplace Level 3 Credits 3 Purpose This unit standard is for people employed in the petrochemical industry. People credited with this unit standard are, in a petrochemical workplace, able to: explain safety requirements for mixing chemicals; prepare to mix chemicals for batch production use; mix and use chemicals for batch processing operations; and complete the batch. Subfield Petrochemical Industry Domain Petrochemical Process and Product Management Status Registered Status date 20 February 2009 Date version published 20 February 2009 Planned review date 31 December 2013 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) NZ Motor Industry Training Organisation (Incorporated) (MITO) Accreditation and Moderation Action Plan (AMAP) reference 0114 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Performance of the elements of this unit standard must comply with relevant site requirements and the following legislation: Hazardous Substances and New Organisms Act 1996; Health and Safety in Employment Act 1992; Resource Management Act 1991. New Zealand Qualifications Authority 2016 9607 version 4 Page 2 of 4 2 This unit standard is intended for, but is not limited to, workplace assessment. While all performance criteria must be met it is noted that all range statements within this unit standard are indicative and dependent on enterprise and site specific equipment, procedures, and practices. Any queries can be directed to the NZ Motor Industry Training Organisation (Incorporated) (MITO). 3 It is expected that candidates for this unit standard have knowledge of safe handling of chemicals. This may be evidenced by holding credit for Unit 21467, Store and handle chemicals for energy and chemical plant. 4 Definitions The Hazchem emergency action code of numbers, letters, and diamonds give information to emergency services. Its use is required by the NZS 5433:2007 Transport of Dangerous Goods on Land. Site requirements mean the site specific documented methods for performing work activities and include health, safety, environmental, and quality management requirements. They may refer to manuals, codes of practice, or policy statements. Elements and performance criteria Element 1 Explain safety requirements for mixing chemicals in a petrochemical workplace. Performance criteria 1.1 Safety requirements are explained in terms of types of chemical identification. Range manufacturer's labels, safety data sheets, manuals, text books, Hazchem. 1.2 Risks and hazards associated with the handling and mixing of chemicals are identified in accordance with site requirements. 1.3 Personal protective equipment for handling the chemicals that are to be mixed is identified and explained in terms of site requirements. Range aprons, face shields, goggles, gloves, chemical suits, breathing apparatus. 1.4 Safety requirements are explained in terms of neutralisation procedures. 1.5 Safety requirements are explained in terms of results of mixing incompatible chemicals. Range exothermic, endothermic, oxidation, corrosion, pyrophoric, atmospheric. New Zealand Qualifications Authority 2016 9607 version 4 Page 3 of 4 Element 2 Prepare to mix chemicals for batch production use in a petrochemical workplace. Performance criteria 2.1 Procedures for the mixing of chemicals are located and used. 2.2 Documentation for the guidance and recording of the batch is assembled in the work area before the procedure commences. 2.3 The area to be used to mix chemicals is selected and cleaned to take account of factors which could affect the materials, the batch operation, and any risks or hazards associated with the procedure. 2.4 Related services are prepared for operation prior to the work beginning. Range ventilation, steam. 2.5 The equipment selected is suitable for mixing of the chemicals, confirmed as being clean, and maintained in safe and good working order. 2.6 Chemicals of the correct identity are obtained in sufficient quantities for the batch. Element 3 Mix and use chemicals for batch processing operations in a petrochemical workplace. Performance criteria 3.1 Chemicals for the batch are measured out, placed in suitable containers, and labelled legibly with product and quantity. 3.2 Checks of chemicals are obtained for verification in accordance with site requirements. 3.3 Batch processing of chemicals is demonstrated in accordance with site requirements. 3.4 Actions are taken to minimise hazards and loss of materials during batch processing operations in accordance with site requirements. 3.5 Documentation for the chemical or batch is completed at the time of manufacture in accordance with site requirements. 3.6 Records are made of all adjustments and any abnormalities during chemical use in accordance with site requirements. New Zealand Qualifications Authority 2016 9607 version 4 Page 4 of 4 Element 4 Complete the batch in a petrochemical workplace. Performance criteria 4.1 Amounts of final product and unused chemicals are quantified and recorded in accordance with site requirements. 4.2 The product is transferred to storage in containers with clear and distinct labels in accordance with site requirements. 4.3 Equipment is dismantled and stored in accordance with site requirements and manufacturer’s recommendations. Range cleaned, decontaminated, packed, labelled. 4.4 Materials are stored in containers accurately labelled to indicate content in accordance with site requirements. 4.5 Waste from the batch is stored in containers or areas designated for disposal purposes. 4.6 Decontamination and cleaning of the area completely removes all residues. 4.7 Documentation is completed and reported in accordance with site requirements. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the NZ Motor Industry Training Organisation (Incorporated) (MITO) info@mito.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016