Establish the causes and location of reported faults in a... process at a petrochemical plant

advertisement

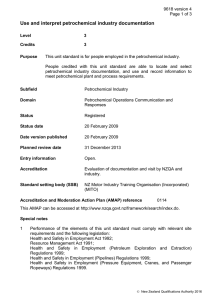

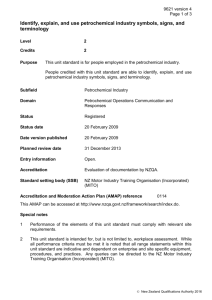

9524 version 4 Page 1 of 3 Establish the causes and location of reported faults in a petrochemical process at a petrochemical plant Level 4 Credits 5 Purpose This unit standard is for people employed in the petrochemical industry. People credited with this unit standard are, at a petrochemical plant, able to: diagnose reported faults in petrochemical process; locate the position of reported faults in a petrochemical process; and verify symptoms and establish causes of reported faults in a petrochemical process. Subfield Petrochemical Industry Domain Petrochemical Operations Communication and Responses Status Registered Status date 20 February 2009 Date version published 20 February 2009 Planned review date 31 December 2013 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) NZ Motor Industry Training Organisation (Incorporated) (MITO) Accreditation and Moderation Action Plan (AMAP) reference 0114 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Performance of the elements of this unit standard must comply with relevant site requirements and the following legislation: Health and Safety in Employment Act 1992; Resource Management Act 1991. New Zealand Qualifications Authority 2016 9524 version 4 Page 2 of 3 2 This unit standard is intended for, but is not limited to, workplace assessment. While all performance criteria must be met it is noted that all range statements within this unit standard are indicative and dependent on enterprise and site specific equipment, procedures, and practices. Any queries can be directed to the NZ Motor Industry Training Organisation (Incorporated) (MITO). 3 Evidence of three types of fault is required from – mechanical, electrical, instrument, process. 4 Definition Site requirements mean the site specific documented methods for performing work activities and include health, safety, environmental, and quality management requirements. They may refer to manuals, codes of practice, or policy statements. Elements and performance criteria Element 1 Diagnose reported faults in a petrochemical process at a petrochemical plant. Performance criteria 1.1 Data are identified, selected, and reviewed to assist in diagnosing faults in petrochemical process. Range maintenance records, analysis results, technical journals, electronic record, vendor's manuals, process data; process data – logs, trends, upstream downstream effects. 1.2 Reasons are given for selecting particular facts from the information identified. 1.3 The diagnosis explains differences between normal operating parameters and fault conditions in relation to equipment specifications. Element 2 Locate the position of reported faults in a petrochemical process at a petrochemical plant. Performance criteria 2.1 Checks and tests are completed to establish the location of faults in accordance with site requirements. 2.2 Checks and tests confirm areas where normal operating conditions are in effect to eliminate them as possible locations of reported faults. 2.3 Locations of reported faults are established and communicated to appropriate personnel. New Zealand Qualifications Authority 2016 9524 version 4 Page 3 of 3 Element 3 Verify symptoms and establish causes of reported faults in a petrochemical process at a petrochemical plant. Performance criteria 3.1 Reported symptoms of faults are verified in accordance with site requirements. 3.2 Preliminary checks and tests are completed to establish the nature of faults. Range 3.3 Consequences of faults are identified in relation to the safety and efficiency of the plant. Range 3.4 breakdown, deviation, continuous, intermittent. immediate, long term. Information concerning the symptoms and cause of faults is communicated to appropriate personnel. Range oral, written, electronic. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the NZ Motor Industry Training Organisation (Incorporated) (MITO) info@mito.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016