Remove and install line hardware on suspension towers using live... hot sticks greater than 110kV

advertisement

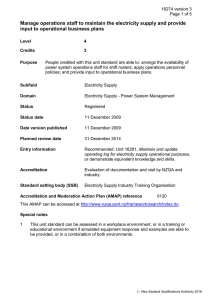

10534 version 4 Page 1 of 4 Remove and install line hardware on suspension towers using live line hot sticks greater than 110kV Level 4 Credits 6 Purpose People credited with this unit standard are able to: plan and prepare for live line hot stick work greater than 110kV on suspension towers; displace and reinstate conductors on suspension towers using live line hot sticks greater than 110kV; replace tower components on suspension towers using live line hot sticks greater than 110kV; and report work on the removal and installation of suspension tower hardware on pole structures using live line hot sticks greater than 110kV. Subfield Electricity Supply Domain Electricity Supply - Live Work Status Registered Status date 16 April 2010 Date version published 16 April 2010 Planned review date 31 December 2014 Entry information Prerequisites: Unit 10538, Inspect, test, and clean live line tools and equipment; Unit 10542, Demonstrate knowledge of live line theory and procedures; Unit 24746, Rig electrical network structures; and Unit 24747, Install and replace insulators and fittings; or demonstrate equivalent knowledge and skills. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Electricity Supply Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0120 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 This unit standard is intended for, but not restricted to, workplace assessment. The range statements across the unit standard can be applied according to industry specific equipment, procedures, and processes. New Zealand Qualifications Authority 2016 10534 version 4 Page 2 of 4 2 Safety of personnel and plant must be a priority throughout the assessment. If the safety requirements are not met the assessment must stop. 3 Performance and work practices in relation to the elements and performance criteria must comply with all current legislation, especially the Electricity Act 1992, and any regulations and codes of practice recognised under that statute; the Health and Safety in Employment Act 1992; and the Resource Management Act 1991. Electricity supply industry codes of practice and documented industry procedures include the Safety Manual – Electricity Industry (SM-EI) Wellington: Electricity Engineers’ Association. A full list of current legislation and industry codes is available from the Electricity Supply Industry Training Organisation, PO Box 1245, Waikato Mail Centre, Hamilton 3240. 4 The phrase in accordance with industry requirements is implicit in all elements and performance criteria in this unit standard. 5 Industry requirements include all asset owner requirements; manufacturers’ specifications; and enterprise requirements which cover the documented workplace policies, procedures, specifications, business, and quality management requirements relevant to the workplace in which assessment is carried out. 6 Asset owner refers to the owner of an electricity supply network that takes its point of supply from Transpower NZ and delivers electricity to industrial, commercial, and residential customers. 7 This unit standard includes but is not limited to – conductors, insulators, cross arms, fittings and other components on poles, towers, other structures. Elements and performance criteria Element 1 Plan and prepare for live line hot stick work greater than 110kV on suspension towers. Performance criteria 1.1 Work is identified. Range inspection requirements, site information, plans, procedures, approvals. 1.2 Tools and equipment are inspected and cleaned. 1.3 Working platforms are inspected and placed. 1.4 Safe working zone is established. New Zealand Qualifications Authority 2016 10534 version 4 Page 3 of 4 Element 2 Displace and reinstate conductors on suspension towers using live line hot sticks greater than 110kV. Range simplex, duplex. Performance criteria 2.1 Operating procedures are explained in a team briefing. 2.2 Conductors are displaced and reinstated on single circuit suspension towers. 2.3 Conductors are displaced and reinstated on double circuit suspension towers. Element 3 Replace tower components on suspension towers using live line hot sticks greater than 110kV. Performance criteria 3.1 Operating procedures are explained in a team briefing. 3.2 Insulators are replaced. Range 3.3 Cross arms are replaced. Range 3.4 includes but is not limited to – porcelain, synthetic, post, pin, strain, suspension. includes but is not limited to – single, double, steel. Fittings are replaced. Range includes but is not limited to – clamp, weights, shackles, saddles, armour rods. 3.5 ‘Y’ configuration and ‘V’ configuration insulator strings are replaced. 3.6 Counterweights are replaced. 3.7 Work site is reinstated. New Zealand Qualifications Authority 2016 10534 version 4 Page 4 of 4 Element 4 Report work on the removal and installation of suspension tower hardware on pole structures using live line hot sticks greater than 110kV. Range includes but is not limited to – condition of removed hardware, test results, system status. Performance criteria 4.1 Work is reported. 4.2 Existing records are updated. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Electricity Supply Industry Training Organisation info@esito.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016