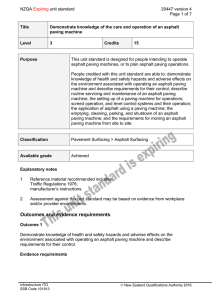

NZQA registered unit standard 13518 version 4 Page 1 of 4

NZQA registered unit standard

Title

13518 version 4

Page 1 of 4

Demonstrate sweeping, placing, compacting, and associated handwork skills for asphalt surfacing

2 Credits 15 Level

Purpose People credited with this unit standard are able to: identify, assess, control, and monitor health and safety hazards and adverse effects on the environment associated with asphalt handwork operations; prepare surfaces by hand for asphalt paving; place and finish asphalt manually; compact asphalt using hand-operated equipment; and sweep and clean up site.

Classification

Available grade

Entry information

Pavement Surfacing > Asphalt Surfacing

Achieved

Critical health and safety prerequisites

Infrastructure ITO

SSB Code 101813

Unit 20455, Demonstrate basic knowledge of safety relating to bituminous materials , or demonstrate equivalent knowledge and skills.

Explanatory notes

1 The following legislation and requirements apply to this unit standard, and must be complied with:

Health and Safety in Employment Act 1992;

Health and Safety in Employment Regulations 1995;

NZTA P9: Specification for Construction of Asphaltic Concrete Paving.

Any legislation or other requirements superseding any of the above will apply, pending the review of this unit standard.

2 Personal protective equipment must be used throughout operations in accordance with company procedures.

3 Assessment against this unit standard must be based on evidence from a workplace context.

4 Definitions

Company procedures refers to all documented policies, procedures and methodologies of the candidate’s employer at the time of training including but not limited to those relating to health, safety, environment, quality, and operations.

Job requirements take account of site conditions to meet contract specifications, and accord with procedures and work instructions written in quality manuals.

New Zealand Qualifications Authority 2020

NZQA registered unit standard 13518 version 4

Page 2 of 4

Outcomes and evidence requirements

Outcome 1

Identify, assess, control, and monitor health and safety hazards and adverse effects on the environment associated with asphalt handwork operations.

Evidence requirements

1.1 Health and safety hazards are identified, assessed, controlled, and monitored in accordance with manufacturer’s instructions, company procedures, and legislation.

Range may include but is not limited to – noise, hazardous material, obstruction, people in the vicinity, personal injury.

1.2 Adverse effects on the environment are identified, assessed, controlled, and monitored in accordance with company procedures and legislation.

Range may include but is not limited to – noise, waterways.

Outcome 2

Prepare surfaces by hand for asphalt paving.

Evidence requirements

2.1 Surfaces and services needing protection from paving operations are identified, protected, and marked in accordance with job requirements.

2.2 Surfaces not accessible by rotary broom or surfaces requiring additional treatment are cleaned as necessary and prepared by hand broom in accordance with job requirements.

Range surfaces

– newly prepared, previously surfaced, irregular, patch repair.

2.3 For minor presurfacing repairs, asphalt is placed by shovel, shaped, and compacted in accordance with job requirements.

2.4 Blinding coat is applied to primed and/or tack-coated surface in accordance with site and job requirements.

Outcome 3

Place and finish asphalt manually.

Range finish

– manually placed, paver laid.

Infrastructure ITO

SSB Code 101813

New Zealand Qualifications Authority 2020

NZQA registered unit standard 13518 version 4

Page 3 of 4

Evidence requirements

Asphalt is placed by shovel in accordance with job requirements. 3.1

3.2 Lute is used to spread asphalt to required shape in accordance with job requirements.

3.3 Lute is used to construct joints and edges and to match and/or abut asphalt to adjacent surfaces in accordance with job requirements.

Outcome 4

Compact asphalt using hand-operated equipment.

Evidence requirements

Compaction equipment is selected in accordance with job requirements. 4.1

4.2 Prestart checks are carried out on mechanical compaction equipment in accordance with manufacturer’s instructions.

4.3 Asphalt is compacted in accordance with job requirements.

Range evidence is required of compacting with – hand rammer, mechanical plate compactor, mechanical vibrating roller.

Outcome 5

Sweep and clean up site.

Evidence requirements

5.1 In areas not accessible by mechanical sweeping equipment, surplus material is swept and removed from work site in accordance with job requirements.

5.2 Temporary protection is removed from surfaces and services in accordance with job requirements.

Planned review date 31 December 2016

Status information and last date for assessment for superseded versions

Process Version Date Last Date for Assessment

Registration

Revision

Review

Review

1

2

3

4

24 March 1998

5 January 1999

27 October 2005

15 March 2012

31 December 2013

31 December 2013

31 December 2013

N/A

Infrastructure ITO

SSB Code 101813

New Zealand Qualifications Authority 2020

NZQA registered unit standard 13518 version 4

Page 4 of 4

0101 Consent and Moderation Requirements (CMR) reference

This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do.

Please note

Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment.

Industry Training Organisations must be granted consent to assess against standards by

NZQA before they can register credits from assessment against unit standards.

Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards.

Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The

CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements.

Comments on this unit standard

Please contact Infrastructure ITO askus@infratrain.co.nz if you wish to suggest changes to the content of this unit standard.

Infrastructure ITO

SSB Code 101813

New Zealand Qualifications Authority 2020