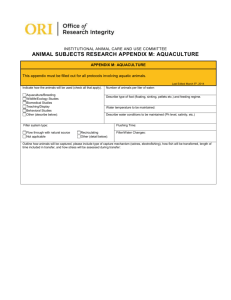

Monitor and maintain reticulated water systems for onshore aquaculture

advertisement

17252 version 3 Page 1 of 3 Monitor and maintain reticulated water systems for onshore aquaculture or holding facilities Level 3 Credits 20 Purpose People credited with this unit standard are able to: describe reticulated water systems for onshore aquaculture or holding facilities; monitor the reticulated water system in an onshore aquaculture or holding facility; and maintain the reticulated water system in an onshore aquaculture or holding facility. Subfield Seafood Domain Aquaculture Status Registered Status date 12 December 2008 Date version published 12 December 2008 Planned review date 31 December 2013 Entry information Recommended: Unit 17255, Test for water quality in an aquaculture facility. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Primary Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0123 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 Definition Company requirements refer to instructions to staff on policy and procedures which are communicated in verbal or written form. These requirements may include but are not limited to – manufacturers’ procedures, company safety procedures, legislative requirements, industry codes of practice and standards. 2 All work practices must meet documented company safety requirements. The documented company safety requirements must meet the obligations of the Health and Safety in Employment Act 1992 and subsequent amendments. New Zealand Qualifications Authority 2016 17252 version 3 Page 2 of 3 Elements and performance criteria Element 1 Describe reticulated water systems for onshore aquaculture or holding facilities. Performance criteria 1.1 The description outlines the sequence of events in the operation of the reticulated water system. Range 1.2 The description includes the function and operating principles of the equipment used in a reticulated water system. Range 1.3 may include but is not limited to – pumps, filters, protein skimmers, ultraviolet units, ozone systems, heat exchangers, blowers, biofilters; evidence is required for five. The description outlines the ways that the reticulation water system is monitored to control water quality. Range 1.4 flow through, partially recirculated, fully recirculated. all of – dissolved oxygen, temperature, pH; at least two of – carbon dioxide, ammonia, nitrate, nitrite, total dissolved gases, turbidity, salinity. The description outlines company safety procedures to be used during monitoring and maintenance of a reticulated water system. Range may include but is not limited to – footwear, clothing, hair restraints and electrical isolation procedures. Element 2 Monitor the reticulated water system in an onshore aquaculture or holding facility. Range one of – flow through, partially recirculated, fully recirculated. Performance criteria 2.1 The pumps are confirmed as being in safe working order during operation in accordance with company requirements. 2.2 The water flow is monitored to meet the needs of the stock being held. Range 2.3 may include but is not limited to – flow meters, bucket test, dissolved oxygen test. The aeration of circulating water is monitored in accordance with company requirements. New Zealand Qualifications Authority 2016 17252 version 3 Page 3 of 3 2.4 Filters are monitored in accordance with company requirements. 2.5 The water quality is monitored in accordance with company requirements. Range may include but is not limited to – oxygen, temperature, pH, carbon dioxide, ammonia, nitrate, nitrite, total dissolved gases, turbidity, salinity; evidence is required for three. Element 3 Maintain the reticulated water system in an onshore aquaculture or holding facility. Performance criteria 3.1 Equipment is maintained in accordance with company requirements. Range 3.2 may include but is not limited to – pumps, filters, protein skimmers, ultraviolet units, ozone systems, heat exchangers, blowers, biofilters; evidence is required for five. Minor repairs are carried out in accordance with company requirements. Range may include but is not limited to – replacing pump valves, cutting and replacing pipes, pigging lines, solvent jointing; evidence is required for three. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Primary Industry Training Organisation at standards@primaryito.ac.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016