Quality Manual-latest draft 270603.doc

advertisement

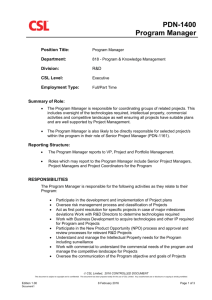

CSL Management System Policy Manual

COMPOUND SECTIONS LIMITED

MANAGEMENT SYSTEM POLICY MANUAL

Document Number: -

CSL-QPM-01

Issuer: -

Damandeep Hillyer

Approved By: -

Management Review Board Team

Revision Number: -

2

Revision Date: -

27/06/03

Organisation Abbreviation: -

CSL

Table of Contents

Introduction

Scope

Documentation Structure of QMS

Overview

Mission

Quality Policy

Policy

Objectives

Organisation Structure

Quality Management System Development

Role of Top Management

Continual Improvement

Core Processes

Procedural References

Glossary

Appendices

Organisation Chart {CSF-001a}

Personnel Index {CSF-001b}

Interaction of Core Processes {CSR-0092}

CSL Contacts List

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 1 of 16

CSL Management System Policy Manual

INTRODUCTION

This quality process manual describes CSL's quality management system, the

processes involved in the operation of our quality management system, the

interaction of these processes within the system, and our established policies as

they relate to TS16949:2002 Quality management systems - Requirements

It is important to understand how our critical (core) processes interact with each

other because a change in one process may have an impact on another process. This

quality management system is focused on process management. We have identified

our critical (core) and support processes and determined how to monitor and

measure these processes. Using data from these measurements, we make informed

decisions on correcting and preventing non-conformances as well as for making

continual improvements related to these processes.

Scope

Due to the nature of our business, this quality process manual addresses our entire

quality management system and the majority of applicable requirements of the

TS16949:2002 Quality management systems - Requirements. Those requirements

not addressed in this manual are covered in related supporting procedures. CSL is

not design responsible for the product.

Documentation Structure of the Quality Management System

The quality management system is documented in the following manner: The quality management system manual is considered a top-level (Level I)

document of CSL quality management system. It defines our quality policy and

objectives; top management's commitment to quality and it identifies our critical

processes and the resulting process owner. The quality management system

manual is revised periodically to keep it up to date with our processes as they are

continually improved. All revisions to this manual are recorded in our electronic

document control system (EDMS). Obsolete or superseded printed, controlled

copies of this document are retrieved and destroyed. Current copies of the

manual are available through our EDMS.

A cross-referencing system identifies the procedures that are linked to the

related core processes identified in this manual. These procedures are necessary

for the proper implementation of these processes.

Quality procedures, a lower level document (Level II) defines the primary

responsibilities within each of the documented processes. They execute the

policies established in this manual and link this document to the process

documents. These procedures are assigned the general prefix CSP and a

reference number. In many cases, a CSP satisfies requirements of several

elements of the International Standard.

Some processes may require the execution of specific tasks. When this is

required, on a routine basis then this activity is documented in the form of an

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 2 of 16

CSL Management System Policy Manual

instruction, a level III document used to support a level II procedure. An

instruction may take the form of a text document, a picture, a shop router

(traveller), a flowchart or other means of consistently communicating the

necessary information in order to perform the task. The process owners are

responsible for creating, co-ordinating, maintaining and improving the

instructions. The amount of detail contained in the instruction may vary

depending on the complexity of the task being performed, the training the

individual has received and/or the education and experience level of the

individual performing the task.

Another type of quality system document is a record, which states results

achieved or provides evidence of activities being performed. Generally speaking,

records need not be under revision control. The document control administrator

maintains most records while the department managers maintain records relevant

to their activities. Access to records is restricted to prevent loss and/or

damage.

The documents that define our quality system are controlled by an electronic

document system. This system is designed to deliver only the current version of

all quality system documents to those individuals who have a need for those

documents and are established as a "user" in the system. Access to view

documents is controlled on document-by-document basis and is provided as

needed. Access to edit documents is even more limited and only specifically

assigned individuals are given this level of access.

The management representative has the authority to revise quality system

documents requiring administrative changes. These changes do not need to be

routed for review but does require approval by the designated final approval

authority of the document.

OVERVIEW

Compound Sections Limited headquarters is located at: Bond Avenue

Bletchley

Milton Keynes

MK1 1JS

Compound Sections limited manufactures and manipulates metal sections and related

sub-assemblies. The company was founded in 1966

MISSION

The quality management system is to be used by all CSL employees to raise

standards, reduce waste and to make CSL a better place to work. Quality at CSL will

continue always to be a consideration in all our internal and external business

activities, with a total company effort and commitment to continuous improvement

and customer satisfaction.

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 3 of 16

CSL Management System Policy Manual

QUALITY POLICY

Policy

Compound Sections Ltd management is committed to QUALITY, ON-TIME

DELIVERY and COST-EFFECTIVENESS, as a supplier of cold rolled section,

fabricated extrusion and light assembly. The company's objectives are to:-

Objectives

1. Consistently meet or exceed our customer's expectations for product quality

and performance, by manufacturing products that meet customer specifications.

2. Monitor customer satisfaction.

3. Monitor on-time delivery of products & services to meet our customer’s

requirements.

4. Improve cost of quality & establish cost reduction programs to reduce all costs

to the lowest possible level.

5. Continuously improve our processes, and systems to enhance our performance

and in turn satisfy our customers.

6. Ensure our personnel are properly trained so they are better able to serve our

customers.

7. Practice good housekeeping so that we never compromise employee safety.

8. Comply with all customer, professional and regulatory legislation.

9. CSL shall work towards using only Selected, Approved, Preferred or Certified

suppliers.

10. Establish & maintain an appropriate level of communication with its customers,

internally & externally, to ensure that it can provide total satisfaction with

respect to products/services.

11. Identify and provide resources needed to meet objectives.

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 4 of 16

CSL Management System Policy Manual

ORGANISATION STRUCTURE

The senior executive of CSL operations is the Managing Director. CSL maintains

written organisation charts designating positions and responsibilities of company

officers, managers and employees. These charts are maintained separately from this

manual and are referenced in the organisation references in the next section. CSL

operations with an impact on quality are more fully described below. Responsibilities

within the quality management system are defined for the following: -

Managing Director

Ensures necessary resources are identified by senior managers and provided

enabling us to accomplish our mission;

Establishes the vision and direction for the organisation;

Creates policy (including quality policy);

Implements and demonstrates the organisations commitment to quality;

Ensures customer requirements are understood throughout the organisation;

Creates the business and quality objectives for CSL;

Reviews and approves continual improvement of core processes.

Works Manager

Identifies necessary resources and communicates them to the Managing

Director;

Co-ordinates production planning;

Ensures production processes are controlled;

Ensures quality policy is understood throughout the department;

Ensures customer requirements are understood.

Creates policy (including quality policy);

Implements and demonstrates the organisations commitment to quality;

Reviews and approves continual improvement of core processes.

Engineering Manager

Identifies necessary resources and communicates them to the Managing

Director;

Creates policy (including quality policy);

Implements and demonstrates the organisations commitment to quality

Responds to customer RFQ's.

Reviews unique customer requirements to determine feasibility and capability;

Reviews and approves continual improvement of core processes.

Co-ordinates with appropriate departments to review unique customer

requirements;

Ensures quality policy is understood throughout the department;

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 5 of 16

CSL Management System Policy Manual

Management Representative/Quality Manager

Communicates performance of the QMS to top management.

Ensures the quality management system is implemented and functioning

effectively;

Ensures relevant personnel are aware of customer requirements;

Ensures quality policy is understood throughout the department;

Establishes and plans internal audits of the quality management system;

Ensures core processes have measures identified to determine effectiveness of

corrective and preventive actions and process improvements;

Is the voice of the customer;

Receives, records and works to resolve customer concerns;

Monitors the status of corrective and preventive actions;

Reviews and dispositions non-conforming material;

Ensure that in-process and final product inspections are carried out;

Chairs Management Review meeting;

Production Control

Control production, packaging and shipping processes;

Implements identified corrective actions.

Establishes customer profile, related products, and new products in Order

Processing System;

Co-ordinates production planning;

Ensures quality policy is understood throughout the department;

Supervisors

Machine set-up;

Control production, packaging and shipping processes;

Understands quality policy;

Implements identified corrective actions.

Ensures customer requirements are fully understood and communicated to

appropriate personnel;

Conduct in-process product inspections;

QUALITY MANAGEMENT SYSTEM DEVELOPMENT

The approach used to develop, implement and maintain our quality management

system consists of the following steps: We determined the needs and expectations of our customers and other

interested parties. An interested party is defined as a person or group having an

interest in the performance or success of our organisation. Interested parties

include our customers, the owner and investors, our suppliers, our community, and

our employees.

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 6 of 16

CSL Management System Policy Manual

We established a quality policy and objectives for our organisation. A quality

policy is a statement from top management that provides the overall intentions

and direction of our organisation as it relates to quality and sets the framework

for our quality objectives. A quality objective is something that is sought or

aimed for that relates to the quality of our organisation and to the quality of our

products and services. Each level in our organisation has established quality

objectives that are relevant to their functions and to our quality policy.

We determined our processes and responsibilities necessary to achieve our

quality objectives. These processes have documented procedures that define

who the "process owner" is and related responsibilities within the process.

Occasionally, some of our processes require a set of detailed instructions that

define how specific activity is to be accomplished. The process owner is

responsible for ensuring these instructions are properly documented, coordinated, and maintained.

Each functional area is responsible for identifying the resources necessary to

accomplish the specific quality objectives. Top management reviews the resource

requirements for final approval. Where resources requirements are not

approved, top management documents the reason for disapproval and the impact

on the process and on the quality management system.

Each process owner is responsible for establishing methods to measure the

effectiveness and efficiency of their processes and any related sub-processes.

The results of these measurements are subject for review by top management

during the management review process.

Each process owner is responsible for using these process measurements as a

means of preventing nonconformity and eliminating their causes and for

identifying root causes for existing non-conformities and implementing

corrective actions.

Process owners are responsible for establishing and implementing our

organisational approach to continual improvement. Through our continual

improvement process, our organisation can determine non-value added steps in a

process, improve existing processes, or determine the most efficient steps to

achieve a desired outcome. Continual improvement is defined as recurring activity

to increase our ability to fulfil requirements more efficiently.

Role of Top Management

Through the leadership of top management and more importantly, through our

actions, we create an environment where employees are fully involved in our quality

management system. The role of top management as it relates to our quality

management system is defined as follows: To establish and maintain the quality policy and quality objectives of our

organisation. The actions of top management create and maintain an environment

in which we can live by our quality policy and achieve our organisation’s

objectives.

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 7 of 16

CSL Management System Policy Manual

Each department manager is responsible for understanding the quality policy,

communicating it to employees in the department and to define how the quality

policy is applicable within the department.

To ensure employees understand our customer requirements. Knowing our

customer requirements helps our employees understand their role and how they

add value to the products and services we provide to our customers.

To ensure our processes are implemented, managed and improved, which will

enable us to meet our customer requirements and our quality and financial

objectives.

To ensure the availability of necessary resources to enable us to meet our

objectives. Necessary resources are defined as people, equipment, and space.

To ensure employees are adequately trained to perform their functions and are

involved in continual improvement of those functions.

To have regularly scheduled reviews of the status of our quality management

system. These reviews include, at a minimum, the results of our internal audits,

customer feedback, process and product conformity, recommendations for

improvements, corrective and preventive actions and status of personnel training.

Continual Improvement

Continual improvement is defined as recurring activity that is used to increase our

ability to meet our customer requirements and our corporate objectives. There are

two fundamental ways to conduct continual process improvement: A. Breakthrough projects which either lead to a major revision or an existing

process leading to a significant cost savings. This is usually accomplished through

the efforts of a cross-functional team outside of routine day-to-day operations.

B. Small-step ongoing improvement activities conducted within existing processes

by people involved in those processes. These improvements are usually based on

the analysis of data provided by the specific process measurements.

The basic actions for continual improvement, whether small-step or breakthrough,

include the following seven-step approach: 1) Analysing and evaluating the existing process/situation to identify areas for

improvement, such as reviewing process data, interviewing people performing the

process and benchmarking activities.

2) Establish the objectives for the improvement. Determine if the improvement

provides an associated cost saving, eliminates a production problem, enables us to

better meet customer requirements or improves our quality management system.

3) Determine possible solutions to accomplish the identified objective.

4) Evaluate the possible solution to determine if the desired outcome is achievable.

Conduct trial tests of potential solutions and/or benchmark other organisations

with a similar process in determining the desired outcome.

5) Implement the recommended change and train employees on the change.

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 8 of 16

CSL Management System Policy Manual

6) Evaluate the implemented changes to determine if the improvement objectives

have been met. If not then return to the beginning of the continual improvement

process.

7) When an interim, implemented change is determined to be effective, the change

is formalised, documents are updated, related processes are reviewed to

determine impact, and employees are trained on the new process.

CORE PROCESSES

1. PROCESS NAME: Quality Management System.

PROCESS OWNER: Management Representative.

PROCESS DESCRIPTION: Process used to ensure CSL develops accurate plans

determining how we will meet our customer product and service requirements. This

system identifies product and process non-conformance. Using process

data/measurements we are able to determine root cause, the corrective actions to

be implemented, steps for preventive action and continual improvement.

PROCESS INPUTS: TS16949 Quality management systems - Requirements, ISO

9004 Quality management systems - Guidelines for performance improvements, top

management involvement, process measurement data.

KEY ACTIONS: Identify critical processes, establish process measurements,

collect and analyse process data to determine preventive and improvement actions,

conduct internal audits of the system, conduct management review on scheduled

basis.

PROCESS MEASUREMENT: Effectiveness of Management Review is measured by

the achievement of our Quality Objectives.

OUTPUT/RECORD: Certification to TS16949:2002, internal audit reports,

management review meeting minutes.

LINKED PROCESS: Processes that directly affect the quality of the product we

deliver to our customers. Control of Product, Manufacturing Process Management,

Suppliers & Purchasing, Inspection Equipment, Maintenance & Control, and Training

processes.

2. PROCESS NAME: Contract Review.

PROCESS OWNER: Engineering / Sales ADM.

PROCESS DESCRIPTION: This process is used to respond to customer request for

quote and capture and review all customer requirements to determine feasibility and

capability prior to acceptance of the order.

PROCESS INPUT: Customer purchase order received by verbal, fax or mail. Access

to order processing software program, co-ordination from applicable departments

when capability and feasibility is not known.

KEY ACTIONS: Ensure customer requirements are identified, identify customer

and/or product in order processing software, create order, operator instructions,

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 9 of 16

CSL Management System Policy Manual

create purchase order when new tooling is required, send operator instructions to

production.

PROCESS MEASUREMENT: Effectiveness of Contract Review is measured by

achievement of in time delivery of product to correct customer specification.

OUTPUT/RECORD: Operator instructions with customer requirements, this serves

as contract review record.

LINKED PROCESSES: Inventory Management, Suppliers & Purchasing, APQP and

Manufacturing processes.

3. PROCESS NAME: Goods In/Receiving.

PROCESS OWNER: Store-man.

PROCESS DESCRIPTION: Process of receiving and accepting of raw material,

assemblies and tooling into inventory.

PROCESS INPUT: Purchase order, bill of material, materials, packing slip.

KEY ACTIONS: Unloading of material, visual checks to determine transit damage,

confirmation with bill of lading and packing slip, visual checks of materials and

tooling to determine acceptance, record items into inventory.

PROCESS MEASUREMENT: Effectiveness of Goods In/Receiving is measured by

the amount of material rejected back to supplier after receipt by Store-man.

OUTPUT/RECORD: Packing slip, supplier corrective action for damaged material.

LINKED PROCESSES: Suppliers & Purchasing, Inventory Management, Control of

Product and Contract Review.

4. PROCESS NAME: Shipping.

PROCESS OWNER: Dispatch Supervisor.

PROCESS DESCRIPTION: Process from finished goods through packaging and

delivery of product to our customer.

PROCESS INPUT: Finished products ready for delivery to customer.

KEY ACTIONS: Determines the appropriate shipping container for product and

review operator instructions for special packaging or shipping instructions. Packages

the products to prevent damage during shipping, produce shipping label; notify

customer for customer pick-up. When required notify the customer that package

has shipped by carrier, complete and file ASN's and Advice notes.

PROCESS MEASUREMENT: Effectiveness of Shipping is measured by the

reduction in complaints from the customer relating to damaged product and delivery

performance.

OUTPUT/RECORD: Shipping record, Advice Note, ASN's, packing labels.

LINKED PROCESSES: Inspection & Testing, Suppliers & Purchasing, Contract

Review and Inventory Management.

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 10 of 16

CSL Management System Policy Manual

5. PROCESS NAME: Product Inspection.

PROCESS OWNER: Production Supervisor/ Quality Manager.

PROCESS DESCRIPTION: Identification and disposition of product/parts that do

not meet customer requirements.

PROCESS INPUT: Product inspection specification, standard inspections required

for this type of product and Control Plans/OQI's.

KEY ACTIONS: Determine customer requirements have been met, source

customers approval for substandard product, ensure faulty product is not sent to

customer, decide on disposition/rework of suspect product.

PROCESS MEASUREMENT: Effectiveness of Product Inspection is measured by

the level of customer returns, internal scrap/rework and Excess/Bonded NC's

raised.

OUTPUT/RECORD: CAR’s/PAR's/NC's, attribute/variable charts, SPC data and

monthly performance reports.

LINKED PROCESSES: Inventory Management, Control of Product, Receiving and

Customer Concerns & Satisfaction.

6. PROCESS NAME: Inventory Storage.

PROCESS OWNER: Production Control/ Store-man.

PROCESS DESCRIPTION: Storage and control of raw materials, stock, customersupplied material, tooling and packaging.

PROCESS INPUT: Purchased material, purchase order, operator instruction, packing

slip, goods received notes, returned goods notes.

KEY ACTIONS: Movement of material, assemblies, packaging and tooling from

receiving, in-process and final audit to safe secure locations.

PROCESS MEASUREMENT: Effectiveness of Inventory storage is measured by the

number of complaints generated internally/externally, relating to damaged material.

OUTPUT/RECORD: Inventory tag, operator instruction, receiving log, storage

location plans.

LINKED PROCESSES: Suppliers & Purchasing, Manufacturing Process.

7. PROCESS NAME: Internal Audit.

PROCESS OWNER: Management Representative/ Quality Manager

PROCESS DESCRIPTION: Process for assessing the processes in the organisation

to determine compliance and improvement activity.

PROCESS INPUT: Process measurement data, documents, and records.

KEY ACTIONS: Planning, checklist development, conducting interviews, observation,

and non-conformance identification, audit report, corrective action request.

PROCESS MEASUREMENT: Effectiveness of Internal Audits is measured using

data related to changes to QMS due to audit activity and process changes as a

result of audit actions.

OUTPUT/RECORD: Checklist, process non-conformance, audit report, corrective

action request.

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 11 of 16

CSL Management System Policy Manual

LINKED PROCESSES: Corrective Action, Preventive Action, Continual Improvement,

and Management Review.

8. PROCESS NAME: Management Review.

PROCESS OWNER: Senior Management.

PROCESS DESCRIPTION: Process to review the status and effectiveness of the

quality management system.

PROCESS INPUT: Process measurement data, customer feedback, internal audit

results, status of corrective and preventive actions, follow-up actions from previous

meetings, recommended improvements.

KEY ACTIONS: Review information provided, determine actions to be taken, update

meeting schedule, and create minutes of meeting.

PROCESS MEASUREMENT: Effectiveness of Management Review is measured by

level of customer satisfaction, improvement activities, achieving objectives and

maintaining TS16949

OUTPUT/RECORD: Meeting minute’s system improvements, resources required

product improvements.

LINKED PROCESSES: Continual Improvement, Corrective & Preventive Action,

Internal Audit and Training.

9. PROCESS NAME: Corrective Action.

PROCESS OWNER: Management Representative.

PROCESS DESCRIPTION: Actions taken to identify and eliminate root cause of

non-conformance.

PROCESS INPUT: Process data, customer feedback, non-conformance report,

records, documents.

KEY ACTIONS: Understand non-conformance, interview process owner and other

interested parties, determine cause of non-conformance, implement actions to

eliminate cause.

PROCESS MEASUREMENT: Effectiveness of Corrective Actions is measured by

verification via internal audits, reduction of similar incidents and customer

feedback/satisfaction.

OUTPUT/RECORD: Completion of CAR, actions to be implemented, processes

changed.

LINKED PROCESSES: Internal Audit, Preventive Action, and Management Review.

10.

PROCESS NAME: Preventive Action.

PROCESS OWNER: Process Owner/ Management Representative.

PROCESS DESCRIPTION: Process used to monitor system to determine if a

potential product/process non-conformance will occur if no action is taken.

PROCESS INPUT: Process measurement information, documents, instructions,

FMEA's, error-proofing activity and contingency planning.

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 12 of 16

CSL Management System Policy Manual

KEY ACTIONS: Monitor process measurements, process parameters, determine

potential non-conformance root cause, develop action plan to eliminate potential nonconformance, determine outcome, standardise change in process.

PROCESS MEASUREMENT: Effectiveness of Preventive Action is measured by

continual improvement i.e. reduction of similar incidents changes to QMS, FMEA's

and internal audit verification/follow up activity.

OUTPUT/RECORD: Process Change, preventive action report.

LINKED PROCESSES: Management Review, Corrective Action, and Continual

Improvement.

11. PROCESS NAME: Continual Improvement.

PROCESS OWNER: Senior Management.

PROCESS DESCRIPTION: Process used to monitor system to determine non valueadded activity. Method used to decrease internal costs.

PROCESS INPUT: Process measurement information, documents, instructions,

benchmarking activity, employee suggestions.

KEY ACTIONS: Monitor process measurements, process parameters, determine

non-value added activity, small steps of improvement, breakthrough improvement.

PROCESS MEASUREMENT: Effectiveness of Continuous Improvement is measured

by the reduction of costs, complaints, increase in customer satisfaction and meeting

quality objectives/targets.

OUTPUT/RECORD: Process change, continual improvement report, and prioritised

reduction plans, quality plans and error proofing activity.

LINKED PROCESSES: Management review, all other processes

12.

PROCESS NAME: Purchasing

PROCESS OWNER: Purchasing Assistant / Production Controller

PROCESS DESCRIPTION: Process of sourcing component materials & consumable

items to meet customer orders and manufacture product.

PROCESS INPUT: Customer order, production schedule, inventory management

system stock levels, resource identified by managers and internal requisition.

KEY ACTIONS: Establish source for material, match requisition requirements to

source, get best price/quality of service, schedule material deliveries in order to

manufacture to customer schedules.

PROCESS MEASUREMENT: Effectiveness of Purchasing is measured by the ability

of the supplier's capability, to deliver on time quality products at the right price

OUTPUT/RECORD: Purchase order sent to supplier, supplier assessment, supplier

questionnaire, approved suppliers list, delivery of material or resource item, reject

notes for non-conforming materials.

LINKED PROCESSES: Goods In, Contract Review, Supplier Performance and

Inspection & Testing.

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 13 of 16

CSL Management System Policy Manual

13.

PROCESS NAME: Customer Satisfaction

PROCESS OWNER: Senior Management / Quality Manager

PROCESS DESCRIPTION: This process is used to assess and measure the

performance of CSL by enhancing customer satisfaction.

PROCESS INPUT: Customer complaints, delivery performance reports, returned

product, customer survey sent out, customer web site links, customers own rating,

verbal comments.

KEY ACTIONS: To set criteria for customer satisfaction measurement, identify

customer requirements and expectations for quality and satisfaction. Monitor

critical customer satisfaction issues and provide feedback measurement of

performance improvement over time.

PROCESS MEASUREMENT: Effectiveness of Customer Satisfaction is measured by

the decline of complaints and higher ratings from our customers, new business from

satisfied customers or the loss of business from poor satisfaction.

OUTPUT/RECORD: Customer survey analysis, continual improvement plans, customer

visits reports.

LINKED PROCESSES: Contract Review, Corrective Action, Preventive Action,

Delivery Performance, Training, Manufacturing, Management Review and Continual

Improvement

14. PROCESS NAME: Training

PROCESS OWNER: Department Manager, Supervisors & Human Resources

PROCESS DESCRIPTION: Process used to ensure that the training needs of all

employees are identified. To demonstrate that training has been planned, provided,

evaluated and documented to determine competency of personnel performing work

affecting product quality.

PROCESS INPUT: New employee starts, change to manufacturing process or

equipment, appraisal/evaluation identifies employees training needs, operator audit

shows need for training.

KEY ACTIONS: Maintain departmental employee training records, train employee

when changes to processes are made, evaluate employee competency levels, provide

external training for statutory training needs, identify resources required to train

employees.

PROCESS MEASUREMENT: Effectiveness of Training to be measured by decrease

of concerns during random operator audits, reduction of customer returns and

internal CAR’s due to operator errors.

OUTPUT/RECORD: Training record, certificates gained, appraisal record, CAR’s,

customer returns record.

LINKED PROCESSES: Manufacturing, Management Responsibilities and Continual

Improvement.

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 14 of 16

CSL Management System Policy Manual

15. PROCESS NAME: Advanced Quality Planning

PROCESS OWNER: Project Leader / APQ Team

PROCESS DESCRIPTION: Process that identifies the expectations and processes

for product quality planning throughout the product lifecycle, to ensure customer

requirements have been met.

PROCESS INPUT: New enquiry comes in, customer requests design or process

change, change of supplier is required and as part of cost reduction activities.

KEY ACTIONS: To address all customer requirements, significant characteristics,

resolve any issues with customer/suppliers, communicate details of changes to

relevant staff, determine feasibility and costs.

PROCESS MEASUREMENT: Effectiveness can be measured by the number of new

enquiries have been dealt with and lead to production, the time taken to implement

engineering changes reduces and the customers rejection of submitted PPAP/RFQ

OUTPUT/RECORD: Team feasibility commitment, enquiry record, PPAP records,

project files, CAR’s raised, project timing plans, capability studies and meeting

minutes.

LINKED PROCESSES: Contract Review, Customer Satisfaction & Concerns,

Manufacturing.

16. PROCESS NAME: Manufacturing

PROCESS OWNER: Works, Engineering & Quality Manager’s

PROCESS DESCRIPTION: This process defines how new jobs get to production

stage and that the controls and documentation required have been provided to meet

customer requirements and reduce the risk of producing non-conforming parts.

PROCESS INPUT: Customer order, new work accepted, APQP planning outputs

identify need for changes, new tooling or changes to current practices identified.

KEY ACTIONS: Identify tooling requirements, equipment, produce and validate

samples parts, approve tooling, develop process routing, identify manufacturing

processes that need operator instructions, conduct capability studies, produce

control plans, write and approve instructions or update existing ones, conduct first

piece approvals, verify job set-up, authorise production.

PROCESS MEASUREMENT: Effectiveness can be measured by SPC charts

performance trends, reduction in non-conforming parts, continuous improvement

actions, internal CAR’s linked to manufacturing.

OUTPUT/RECORD: Control plans, OQI’s, tooling records, FMEA’s, first off samples

& records, PPAP submissions.

LINKED PROCESSES: Contract Review, Training, Management Review, Continual

Improvement, and APQP.

Release Date: - 28/06/2016

Date Printed: - 28/06/2016 20:09:00

Page 15 of 16

CSL Management System Policy Manual

PROCEDURAL REFERENCES

Advanced Quality Planning

Management Responsibilities

Internal Audits

Control of Documents

Corrective Action & Problem Solving

Customer Concerns & Satisfaction

Inspection & Testing

Inspection Equipment Control, Maintenance & Calibration

Laboratory Testing (Internal/External)

Measurement Systems Development & Qualification

Preventive Action

Quality System Effectiveness & Continuous Improvement

Statistical Methods

Contract Review

Manufacturing Process Management

Production Equipment Maintenance

Control of Product

Part Approval Process

Inventory Management

Suppliers & Purchasing

Tooling Management

Training Needs

Personnel Job Responsibilities

CSP-002

CSP-003

CSP-004

CSP-005

CSP-010

CSP-011

CSP-015

CSP-016

CSP-017

CSP-018

CSP-020

CSP-021

CSP-022

CSP-023

CSP-027

CSP-029

CSP-030

CSP-032

CSP-035

CSP-037

CSP-039

CSP-040

CSI-008-HR

GLOSSARY

EDMS Electronic Document Management System

PROCESS Set of interrelated activities which transforms inputs into outputs.

ASN Advanced Shipping Notice

QMS Quality Management System

RFQ Request For Quote

APPENDICES

Organisation Chart

Personnel Index

Interaction of Core Processes

CSL Contacts List

CSF-001a

CSF-001b

CSR-0092

N/A

Release Date: - 28/06/2016

Page 16 of 16

Date Printed: - 28/06/2016 20:09:00