12601170_Main.doc (338Kb)

advertisement

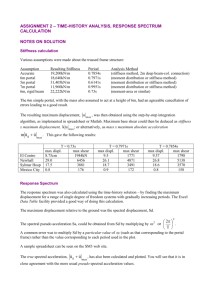

Real-Time Integral Based Structural Health Monitoring I. Singh-Levett, J.G. Chase & C.E. Hann Department of Mechanical Engineering, University of Canterbury, Christchurch, New Zealand B.L. Deam Department of Civil Engineering, University of Canterbury, Christchurch, New Zealand ABSTRACT: An algorithm has been developed to provide real-time structural health monitoring during earthquake events. For a given input ground acceleration the algorithm matches the Bouc-Wen hysteresis model to structural response data using piecewise least squares fitting. The methodology identifies pre-yield and post-yield stiffness, elastic and plastic components of displacement and final residual displacement. This approach is particularly useful for rapid assessment of structural safety by owners or civil defense authorities. The algorithm is tested with simulated response data using the El Centro and Kobe earthquake records. Using simulated data for a two degree of freedom shear building model, the algorithm captures stiffness to within 2% of the real value and permanent deflection to within 5% when significant non-linear response occurs. This is achieved with acceleration data sampled at 1KHz and displacement data sampled at 10Hz. 1 INTRODUCTION Structural Health Monitoring (SHM) is the process of comparing the current state of a structure’s condition relative to a baseline state and determining the existence, location, and degree of damage that may exist, particularly after a damaging input, such as an earthquake or other large environmental load. Many current vibration-based SHM methods, particularly for large civil structures, are based on modal parameter damage detection in both the time series and frequency domain. Changes in modal parameters, such as frequencies, mode shapes and modal damping, are a result of changes in the physical mass, damping and stiffness properties of the structure (Doebling et al, 1996). SHM can simplify typical procedures of visual or localized experimental methods, such as acoustic or ultrasonic methods, magnetic field methods, radiography, eddy-current methods or thermal field methods (Doherty, 1997), as it does not require visual inspection of the structure and its connections or components. SHM in Civil structures is useful for determining the damage state of a structure. In particular, the ability to assess damage in real-time or immediately after a catastrophic event, such as an earthquake or terrorist bomb blast, would allow Civil Defence authorities to determine which structures were safe. Current methods relying on the identification of modal parameters are more applicable to steel-frame and bridge structures where vibration response is more linear. Modal-based methods can also be insensitive to localised damage and non-robust in the presence of noise. Another drawback of current methods is the inability to be implemented in real-time, as the event occurs. For example, current wavelet and ERA (Eigensystem Realisation Algorithm) methods (Lus et al ,2004 and Caicedo et al, 2004) require the entire measured response to process and identify damage. Other identification methods with potential near real-time SHM have been employed to identify modal parameters by using the adaptive fading Kalman filter technique (Loh et al, 2000), and an Adaptive H Filter (Sato and Qi, 1998). However these methods involve significant computational complexity. The approach presented in this paper uses an integral-based linear least squares method to identify changes in structural stiffness and permanent displacement. This is achieved by matching the BoucWen Hysteresis model (Bouc, 1967) to ground acceleration and structural response data. This approach can be easily implemented in real time, is robust in the presence of noise and is shown to accurately identify localized damage by simulation. 2 METHODOLOGY tem is over determined, and the required unknowns ki , i 1..N can be found using linear least squares. 2.1 Bi-Linear Stiffness Model and Identification The motion of a structure undergoing earthquake acceleration is defined: M x Cx K (t )x M xg (1) where M is the mass matrix, C is the viscous damping matrix, K(t) is the time varying stiffness matrix, x is the displacement vector, x is the velocity vector, x is the acceleration vector and xg is the ground acceleration vector. For a single degree of freedom, equation (1) reduces to the form: mx cx k (t ) x mxg (2) where m, c, and k(t) are scalar quantities. In order to estimate a time-varying stiffness using only the structural and ground acceleration data, the displacement and velocity terms in Equation (2) are replaced by integral approximations defined:. t x xdt 0 t x t xdt t 0 0 (3) (4) 2.2 Bouc-Wen Hysteresis Model and Identification The motion of a structure undergoing earthquake acceleration with Bouc-Wen hysteresis is given by the matrix equation defined: M x Cx K e x(t ) K h z (t ) M xg (9) where Ke is the pre-yield stiffness matrix and Kh is the post-yield stiffness matrix. The vector z(t ) represents hysteretic displacement and is governed by the equation: ni zi (10) zi ri 1 0.5(1 sgn( ri zi )) , i 1..N Yi (2) of degrees where N is the number of freedom, Y is the yield displacement and n is a shaping parameter. 2.2.1 Displacement and Velocity Estimation Estimation of the displacement and velocity by integration of measured acceleration is naturally subject to drift and numerical error. This error is corrected using the 10Hz measured displacement data which is assumed to be a 100pt backward moving average from 1KHz sampled data. Thus an integration displacement error at 0.1s intervals is defined: where δ and σ take account of initial conditions and errors due to noise. ei xm (0.1i) x (0.1i) , i 1..N Substituting Equations (3) and (4) into Equation (2) a revised equation of motion is developed: where ei is the error at the time t 0.1i , xm (t ) is the 10Hz measured displacement and x (t ) is a 100pt backward moving average of the integrated displacement x(t ) defined: t t t mx c xdt k (t ) xdt mxg (5) 0 0 0 Assuming that k(t) is a piecewise constant function over N fixed time intervals Δt, k(t) is defined: k (t ) ki , (i 1)t t it , i 1..N (6) t t x(t ) xdt dt (12) 0 0 An integration velocity error is calculated by numerical differentiation: ci (ei ei 1 ) / 0.1 Equation (5) can then be reformulated: t t t k i xdt dt i t i mxg mx c xdt , 0 0 0 t i t t i t , i 1..N (7) (11) (13) The time-varying corrected velocity is then calculated by integrating acceleration and adding the velocity error: t v(t ) xdt ci , 0.1(i 1) t 0.1(i ) , i 1..N (14) where i k i , 0 i k i (8) Choosing for example 10 values of t in the interval t i t t i t will give in total, 10N linear equations in 3N unknowns ki , and i . Thus the linear sys- where 0.1N is the total time interval of interest The time-varying corrected displacement is calculated by twice integrating acceleration, adding the interpolated velocity error and adding the displacement error: t t d (t ) xdt dt ci [t 0.1(i)] ei 0 0 0.1(i 1) t 0.1(i ) , i 1..N Equation (16) can be rewritten: (15) Figures 1 and 2 show an example where the real velocity and displacement are compared with those estimated using equations (18) and (19). Acceleration data used in estimation had 10% uniformly distributed noise applied. Displacement data used had 3% normally distributed noise applied. k p (t )d (t ) Z (t ) mxg mx cv (t ) (17) where k p k e k h and Z (t ) k h ( z(t ) x(t )) The time varying term Z (t ) is then represented by a piecewise constant function over N fixed time intervals Δt, defined: Z (t ) is defined: Real Velocity Adjusted Velocity 0.06 Z (t ) Z i , (i 1)t t it , i 1..N (19) 0.04 Equation (11) can then be reformulated: 0.02 k p d (t ) Z i mxg mx cv (t ) , 0 (i 1)t t it , i 1..N (20) -0.02 -0.04 -0.06 35 35.5 36 36.5 37 37.5 38 38.5 k p (t ) k p , j , ( j 1) tkp t jtkp , j 1..M Figure 1. Comparison of Real and Estimated Velocities -0.012 Real Displacement Adjusted Displacement -0.014 (21) for some chosen interval tkp . In a similar way to section 2.1 an overdetermined system of linear equations in the unknowns z i , i 1..N and k p , j , j 1..M can be set up and solved by linear least squares. The average of the values of k p , j where the variation of is less than a given tolerance is used to approximate the constant term k p k e k h . -0.016 -0.018 -0.02 -0.022 -0.024 -0.026 -0.028 -0.03 -0.032 However simulation has shown that k p and zi can be most accurately found by allowing movement in k p . That is a time varying k p is defined: 37.6 37.8 38 38.2 38.4 38.6 38.8 Figure 2. Comparison of Real and Estimated Displacements Note how the drift error is corrected at 0.1s intervals. This method of velocity and displacement estimation makes the algorithm very robust in the presence of noise. Assuming that the bi-linear factor α (typically 0.050.1) is known for the Bouc-Wen element, k e and k h can then be found: k e k p , k h (1 )k p (22) Thus the permanent displacement parameter ( z x) i is defined: ( z x ) i Z i / k h (23) 2.2.2 SDOF 2.2.3 2DOF For a single DOF Equation (9) reduces to: mx cx k e x (t ) k h z (t ) mxg (16) where the velocity and displacement are estimated by adjusted integration using the procedure described in section 2.2.1, and the unknowns are k e , k h and z. A 2-DOF shear building model is defined: m2 x2 c 2 x 2 k e 2 ( x 2 x1 ) k h 2 ( z 2 z1 ) m2 xg (24) Real Stiffness Variation m1 x1 c1 x1 k e 2 ( x1 x 2 ) k e1 x1 k h 2 ( z1 z 2 ) k h1 z1 m1 xg (25) 50 45 40 where the subscript 1 denotes the bottom floor. Stiffness (N/m) 35 The unknowns in equation (25) are k e1 , k h1 , k e 2 , k h 2 , z1 and z2 , where z i is defined in Equation (10). 30 25 20 15 Adding Equations (22) and (23) eliminates the unknown z2 which yields: 10 5 m1 x1 m2 x2 c1 x1 c2 x 2 (k e1 k h1 ) x1 k h1 ( z1 x1 ) (m1 m2 ) xg (26) Equation (26) can be rewritten: k p1d1 Z1 (t ) (m1 m2 ) xg m1 x1 m2 x2 c1v1 c2 v2 0 0 10 20 30 40 50 60 Time (s) Figure 3. Real Stiffness Variation Fitted Stiffness Variation 60 (27) 50 40 Stiffness (N/m) Equation (27) is in the same form as Equation (17) and thus the same procedure in section 2.2.2 can be applied to find the parameters ( z1 x1 ) , ke1 and k h1 . Rearranging Equation (24) and substituting the fitted parameters ( z1 x1 ) ke1 and k h1 yields: (k e 2 k h 2 ) x2 k h 2 ( z2 x2 ) (28) m2 xg m2 x2 c2 x 2 k e 2 x1 k h 2 z1 30 20 10 \ 0 0 10 20 30 40 50 60 Time (s) Figure 4. 20% Fitted Stiffness Profile where the only unknowns now are k e 2 , k h 2 and z2 . The same procedure in section 2.2.2 can now be applied to find the parameters ( z2 x2 ) , k e 2 and k h 2 . 3.2 SDOF Model With Bouc-Wen Hysteresis 3.1 SDOF Bi-Linear Model Simulations were conducted using the Kobe earthquake record and a 1kg mass with initial stiffness of 39.577N/m, bi-linear factor of 0.1, yield point of 45mm and a hysteresis shaping parameter n=2. The algorithm was tested using a single degree of freedom bi-linear elastic system subject to the El Centro excitation with up to 10% randomly distributed noise applied to acceleration measurements. Figure 5 shows the real variation of the permanent displacement parameter z (t ) x(t ) over the course of the excitation: 3 RESULTS Real (Z-X) 0.15 The system had a mass of 1kg with a pre-yield stiffness of 39.577N/m and a bi-linear factor of 0.1. The yield displacement was 45mm. Permanent Displacement (m) Figures 3 and 4 show the real and fitted stiffness variation, demonstrating that the algorithm accurately identifies stiffness and the time and degree of yielding occurring, even in the presence of strong noise. Stiffness is fitted at 0.2s intervals. 0.1 0.05 0 -0.05 -0.1 0 5 10 15 20 25 Time (s) Figure 5. Real Variation of z (t ) x(t ) 30 35 40 45 Parameters were fitted using data subject to 5% acceleration noise and 3% displacement noise. Stiffness was fitted at 3s intervals while permanent displacement was fitted at 0.6s intervals. Figure 6 shows the variation of the fitted parameter z (t ) x (t ) with time. point of 45mm and shaping parameter n=2. The resulting structure had a fundamental natural frequency of 1Hz. Figures 7 and 8 show the real value of the permanent displacement z (t ) x (t ) for the top and bottom floors: Real (Z-X) - Top Floor 0.12 Fitted (Z-X) 0.1 Permanent Displacement (m) 0.15 Displacement (m) 0.1 0.05 0 0.08 0.06 0.04 0.02 -0.05 0 -0.1 -0.02 0 10 20 30 40 50 60 Time (s) 0 5 10 15 20 25 30 35 40 45 Time (s) Figure 6. Fitted Variation of z (t ) x (t ) Figure 7. Top Floor Permanent Displacement (Real) The algorithm reports a final residual displacement as 15mm which compares well to the real value of 14.9mm. x 10 14 12 Permanent Displacement (m) The most accuracy in stiffness kp(t) was obtained when z (t ) x (t ) was minimal. Thus only 3s intervals which had a maximum change of z (t ) x (t ) less than 1mm were used to calculate kp. As discussed in section 2.2.2 the average kp is used to approximate the linear stiffness and the results are shown in Table 1. Real (Z-X) - Bottom Floor -3 16 10 8 6 4 2 0 Table 1. Fitted Linear Stiffness __________________________ Period Stiffness ___________________ N/m __________________________ 1 39.18 5 38.17 6 38.75 7 39.04 8 38.60 9 38.83 10 36.86 11 38.74 12 37.92 __________________________ Mean 38.45 Std Dev 0.72 3.3 2DOF Model with Bouc-Wen Hysteresis The algorithm was tested using two identical Bouc-Wen elements in a shear building arrangement, subject to the El Centro record. The elements had stiffness of 102.64N/m, bi-linear factor of 0.1, yield -2 0 10 20 30 40 50 60 Time (s) Figure 8. Bottom Floor Permanent Displacement (Real) Stiffness and Displacement parameters were fitted from acceleration data with 5% noise and displacement data with 3% noise. Stiffness was fitted at 4s intervals while Displacement was fitted at 0.4s intervals. Figures 9 and 10 show the fitted permanent displacements for the top and bottom floor respectively: Fitted (Z-X) - Top Floor identifies stiffness and permanent displacement. Only the results of the fitted stiffness in time periods where there is minimal change in z(t)-x(t) are used to identify the overall linear stiffness kp. This avoids potential tradeoff that can occur between kp and z(t)x(t) during periods of significant yielding. 0.1 0.09 Permanent Displacement (m) 0.08 0.07 0.06 0.05 0.04 0.03 0.02 0.01 0 0 10 20 30 40 50 60 Time (s) Figure 9. Fitted Top Floor Permanent Displacement The two degree of freedom example given shows that the algorithm can accurately identify stiffness and permanent stiffness in a multiple degree of freedom situation. Since the algorithm effectively decouples the fitting process into separate optimizations for each floor it is easily generalized to higher degrees of freedom. Fitted (Z-X) - Bottom Floor 0.02 Once the hysteresis parameters zi are identified, the further hysteretic components of yield point Y and shaping parameter n could be found from Equation (10). 0.018 Permanent Displacement (m) 0.016 0.014 0.012 In summary this paper provides a highly efficient and accurate method for identifying linear stiffness and permanent displacement in multi-story buildings under seismic loads as well as providing further information on Bouc-Wen hysteretic components. 0.01 0.008 0.006 0.004 0.002 0 0 10 20 30 40 50 60 Time (s) 5 REFERENCES Figure 10. Fitted Bottom Floor Permanent Displacement As with the single degree of freedom case, stiffness values were only fitted where the change in bottom floor permanent displacement ( z1 x1 ) was less than a 2mm tolerance. Table 2 lists the values: Table 2. Fitted Stiffness Values For Both Floors ______________________________________________ Top Floor Bottom Floor ___________________ _____________________ Period Stiffness (N/m) Period Stiffness (N/m) ______________________________________________ 2 104.43 2 98.27 3 103.47 3 98.67 4 104.35 4 99.16 5 104.53 5 99.12 6 103.54 6 99.02 7 104.48 7 100.19 8 105.12 8 99.28 ______________________________________________ Mean 104.28 Std Dev 0.58 4 99.11 0.59 Bouc, R. 1967 “Forced Vibration of Mechanical Systems with Hysteresis” Proceedings of the 4th Conference on Non-Linear Oscillation. Prague, Czechoslovakia Caicedo, J. M., Dyke, S. J. and Johnson, E. A. (2000) “Health Monitoring Based on Component Transfer Functions” Proceedings of the 2000 International Conference on Advances in Structural Dynamics, Hong Kong, December 13-15. Doebling, S.W., Farrar, C.R., Prime, M.B., and Shevitz, D.W. (1996a) “Damage Identification and Health Monitoring of Structural and Mechanical Systems from Changes in Their Vibration Characteristics: a Literature Review” Los Alamos National Laboratory, Report LA-13070-MS. Doherty, J. E. (1987) “Non-destructive Evaluation,” Chapter 12 in Handbook on Experimental Mechanics, A. S. Kobayashi Edt., Society for Experimental Mechanics, Inc. Loh, C.-H., Lin, C.-Y., and Huang, C.-C. (2000) “Time Domain Identification of Frames under Earthquake Loadings” Journal of Engineering Mechanics, Vol.126, No.7, pp 693703. DISCUSSION & CONCLUSIONS In the Bi-Linear case the algorithm accurately identifies changes in stiffness due to yielding using only acceleration data with up to 20% normally distributed noise applied. Using the Bouc-Wen Hysteresis model for a single degree of freedom system the algorithm accurately Lus, H. and Betti, R. (2000) “Damage Identification in Linear Structural Systems” Proc. of the 14th ASCE Engineering Mechanics Conference, Austin, Texas, May 21–24. Sato, T. and Qi, K. (1998) “Adaptive H Filter: Its Application to Structural Identification” Journal of Engineering Mechanics, Vol.124, No.11, pp 1233-1240.