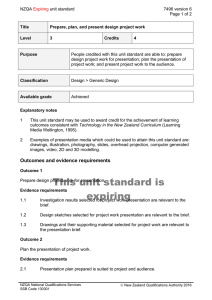

NZQA unit standard 22702 version 2

advertisement

NZQA Expiring unit standard 22702 version 2 Page 1 of 5 Title Install and commission commercial refrigeration and air conditioning Level 3 Purpose Credits 15 This unit standard is for people who work, or intend to work, in the refrigeration and air conditioning sector of the engineering industry, and is intended for use in the training of installers and technicians of refrigeration and air conditioning equipment. People credited with this unit standard are able to: demonstrate knowledge of pre-installation activities for refrigeration and air conditioning systems; install the components of refrigeration and air conditioning systems; perform pre-start commissioning procedures; perform start-up commissioning procedures; and provide information to operators and complete required documentation. Classification Mechanical Engineering > Refrigeration and Air Conditioning Available grade Achieved Critical health and safety prerequisites Open. Explanatory notes This unit standard is References expiring Building Act 2004; Version 2 of this unit standard was republished to include Replacement Information 1 Electricity Act 1992; Electricity Amendment Act 1997; Hazardous Substances and New Organisms Act 1996; Health and Safety in Employment Act 1992; Ozone Layer Protection Act 1996; Electricity Regulations 1997; AS/NZS 1677:1998, Refrigerating systems – Refrigerant classification; AS/NZS 3000:2000, Electrical installations; Code of Practice for the reduction of emissions of fluorocarbon refrigerants in refrigeration and air conditioning applications. Institute of Refrigeration, Heating and Air Conditioning Engineers of New Zealand (IRHACE New Zealand), 2001. Available from IRHACE, 28 E Lambie Drive, Manukau City, http://www.irhace.org.nz/. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard 2 22702 version 2 Page 2 of 5 Definitions Commercial refrigeration and air conditioning systems refers to items such as: refrigeration equipment as found in retail food outlets, truck and shipping-container refrigeration, horticultural cool room refrigeration, controlled atmosphere fruit stores; and air conditioning equipment as found in commercial buildings. Organisational procedures refer to documents that include: organisational rules, codes, and practices; equipment operating instructions; production specifications; documented quality management systems; and health and safety requirements. Outcomes and evidence requirements Outcome 1 Demonstrate knowledge of pre-installation activities for refrigeration and air conditioning systems. Evidence requirements 1.1 Installation drawings, schedule of materials, and instructions are described in terms of checks that should be made against site conditions. 1.2 Two examples are given of modifications that may be required to suit site conditions. 1.3 Procedures for assembling materials and verifying them against a schedule of materials are described. 1.4 Procedures for verifying ancillary service connections and reporting any discrepancies are described. Range 1.5 may include but is not limited to – water, electricity, plumbing. This unit standard is expiring Two examples are given of situations where permits and/or consents are required for installations. Outcome 2 Install the components of refrigeration and air conditioning systems. Evidence requirements 2.1 Major components are positioned and secured in accordance with drawings, designs, specifications, and instructions. Range 2.2 refrigeration components include but are not limited to – compressor, condenser, evaporator, metering device; air conditioning components include but are not limited to – compressor, outdoor fan coil, metering device, indoor fan coil. Ancillary components and installation materials are installed in accordance with drawings, designs, specifications, installation considerations, and instructions. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard Range 2.3 22702 version 2 Page 3 of 5 ancillary components may include but are not limited to – valves, controls, filters, driers; installation materials may include but are not limited to – supports and bracketing to secure pipework, piping, tubing, capping, thermal insulation; installation considerations may include but are not limited to – nitrogen purging, internal cleanliness. The work of associated tradespeople is identified and reported in accordance with organisational procedures. Outcome 3 Perform pre-start commissioning procedures. Evidence requirements 3.1 Safety devices are tested and calibrated and systems are verified as safe to be exposed to operating pressures. 3.2 Controls are tested and set to meet specified performance and safety requirements. Range 3.3 controls equipment may include but is not limited to – programmable logic control (PLC), electronic, electromechanical, pneumatic. Electrical systems are checked, and compliance with performance and safety requirements is verified. Range checks include but are not limited to – earth continuity, insulation resistance, polarity, voltage. 3.5 This unit standard is expiring Motor ratings are verified against fuse ratings and overload settings. 3.6 Motor and pump rotation directions are verified. 3.7 Fluid flows are tested and balanced as required. 3.8 Actions are taken as required to clear foreign solid matter from pipe-work and/or associated components. 3.9 System and component integrity is confirmed by the use of appropriate leak detection methods and equipment. 3.10 Compressor is checked and, if required, charged with appropriate lubricant. 3.11 System is evacuated to pull down to 500 microns or less to ensure that moisture, oxygen, and non-condensables are removed. 3.4 Visual and tactile tests are performed to ensure the mechanical integrity of all electrical terminations and connections. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard Range 22702 version 2 Page 4 of 5 evacuation tools include but are not limited to – Schraeder core removal tool, vacuum analyser, vacuum pump, short large-bore vacuum hose, solenoid valve, isolating valves. 3.12 Where triple evacuation is required, vacuums are broken with dry nitrogen. 3.13 Vacuums are broken with appropriate refrigerant after final evacuation. Outcome 4 Perform start-up commissioning procedures. Evidence requirements 4.1 System is checked and charged using appropriate method and refrigerant in accordance with system specifications. Range method may include but is not limited to – suction super-heat set and sub-cooling checked after system is running and stabilised, compressor current measured and control settings verified for operational performance, lubricant and/or refrigerant levels and flows adjusted as necessary for required performance. 4.2 Lubricant and/or refrigerant identification labels are affixed to appropriate parts of the system in accordance with legislative requirements. 4.3 System performance data is recorded as required by operational specifications and instructions. Range temperatures, pressures, super-heat, sub-cooling, current draw, fluid flows, humidity, noise, vibration. This unit standard is Provide information to operators and complete required documentation. expiring Outcome 5 Evidence requirements 5.1 Operators are familiarised with manuals and operating instructions. 5.2 Operators are instructed to operate refrigeration and air conditioning systems within design parameters, and in accordance with operational and worksite procedures. 5.3 Documentation is produced outlining labour and materials used, and any details required for a warranty in accordance with organisational procedures. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016 NZQA Expiring unit standard Replacement information 22702 version 2 Page 5 of 5 This unit standard was replaced by unit standards 28959, 28963 and 29100. This unit standard is expiring. Assessment against the standard must take place by the last date for assessment set out below. Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 20 June 2006 31 December 2019 Review 2 18 June 2015 31 December 2019 Republish 2 13 September 2015 31 December 2019 Consent and Moderation Requirements (CMR) reference 0013 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. This unit standard is expiring Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Competenz SSB Code 101571 New Zealand Qualifications Authority 2016