12649227_Morison Falling film evaporator design full paper.docx (1.808Mb)

advertisement

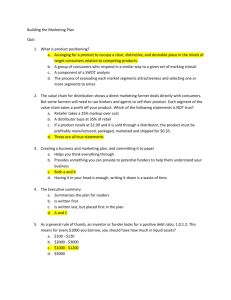

REDUCTION OF FOULING IN FALLING-FILM EVAPORATORS BY DESIGN Ken R Morison Department of Chemical and Process Engineering, University of Canterbury, Private Bag 4800, Christchurch, New Zealand ABSTRACT Falling-film evaporators are widely used for the concentration of liquid foods, especially milk prior to spray drying. Given that an evaporator is a heat exchanger, it is often assumed that fouling is similar in heat exchangers and evaporators. This paper describes a number of features of falling-film evaporators that have been studied in recent years, and hence it seeks to show that attention to design detail should lead to lower rates of fouling. Typically fouling is due to poor liquid distribution to the tubes, which leads to drying of the milk films, or causes increases in viscosity to the point where flow stops. The minimum flow rates required to ensure wetting of tubes and flow into the tubes have been established but distributor holes must be correctly sized and drilled to give equal flow to all evaporator tubes. Blockage of distributor holes during operation can be avoided by installation of filters. Vapour flows from flashing or from unequal evaporation in the multiple passes of the same effect can interfere with the liquid flow from distributor plates but this can be overcome by the installation of vapour tubes in distributor plates. When correctly designed and fabricated, it is likely that falling film evaporators can operate in excess of 20 hours without excessive fouling or bacterial growth. INTRODUCTION Falling-film evaporators are widely used for the concentration of liquid foods, especially milk prior to spray drying. Typically milk enters with about 13% solids content and is evaporated to about 50% solids. The milk flows as a film down the inside of tubes which are up to 15 m long. Multiple effects operating under vacuum enable high thermal efficiency while maintaining temperatures below about 70 °C to minimise heat damage. Studies of the fouling and cleaning of these evaporators have not been as numerous as studies of milk fouling in heat exchangers. Chen and Bala (1998) showed that surface temperatures need to be above about 70 °C for significant surface fouling of milk to occur but most parts of milk evaporators operate below this temperature. Therefore, most of the fouling is unlikely to be the same as heat transfer fouling seen in heat exchangers such as those used for pasteurisation or ultra-heat-treatment (UHT) of milk. Fouling studies have often focused on pipe surfaces and, in the context of evaporators, typical examples are the work of Rausch et al. (2013) and Karlsson et al. (2013) who studied the fouling in a single evaporator tube of a model solution of maize stillage and black liquor from pulping respectively. They were able to track the changes in heat transfer over time for different conditions. However in an industrial evaporator there can be several thousands of tubes and significant design effort is required to ensure equal and steady flow into all of the tubes in any one pass. A typical modern evaporator is shown in Figure 1. Not shown before the evaporator are the preheaters and feed pump. The evaporator as shown has four effects, the first two of which have a mechanical vapour recompression (MVR) fan supplying the required energy, and the last two are powered by steam using thermal vapour recompression (TVR). To ensure sufficient wetting of the tubes (see subsection below) there are, in Figure 1, two passes in the first effect and five in the second. The vessels are designed with partitions so that milk does not mix between passes. There can be about 1000 evaporator tubes in the first passes, reducing to 100 or fewer in the final passes. Steam Feed Fan Condenser Concentrate Figure 1. A typical evaporator configuration with MVR and TVR stages. For clarity some pumps are not shown in effect 2. At the top of each pass a distributor plate spreads the liquid so that it flows into all the tubes of the pass. At the bottom, liquid passes via a pipe and a transfer pump to the next pass. Typically the feed flow rate is controlled to be constant while the fan speed and flow rate of steam into the third effect are adjusted to achieve a consistent total solids concentration in the product. Bouman et al. (1988) was quite clear about the need for good distribution of liquid: “It is recognized that a critical component in falling-film evaporators is the distribution device. The product must be distributed uniformly at the feed inlet to assure a sufficient supply of liquid to each tube. If a distributor does not satisfy this condition adequately, individual heating tubes will not be provided with sufficient liquid and there is consequently the danger of deposit formation.” They found that up to 1.3% of the total whole milk feed solids was lost as deposit on the tube walls. To obtain suitable functional properties in the final milk powder, the milk is preheated at temperatures from 72 to 120 °C (Singh, 2007) using plate heat exchangers, shell and tube heat exchangers and/or direct steam injection. Given the high temperatures the build-up of deposit in these heat exchangers can be significant so often two preheating units in parallel are required to enable changeover and cleaning during operation. Fouling in the preheaters is beyond the scope of this paper, but the effect of preheater fouling on evaporator fouling is discussed below. This paper will summarise past work and will attempt to show that fouling in falling-film evaporators can be minimised by appropriate attention to design. TUBE WETTING The wetting rate is defined as the mass flow rate per unit circumference of the tubes (kg s–1 m–1). The minimum wetting rate is the rate required to ensure complete wetting. The selection of average wetting rates for the evaporator tubes is a key design step. They can be determined using mass balance calculations. If the wetting rate is too low, each evaporator effect can be split into two or more passes. An example is given by Morison and Hartel (2007). Minimum wetting rates The minimum wetting rates for different liquids are subject to some uncertainty. An early significant work on film wetting was that of Hartley and Murgatroyd (1964) which established the physical phenomena involved and suggested equations for determination of the flow rates required to achieve complete wetting. The minimum wetting rate is defined as the mass flow rate per unit circumference (kg s–1m–1) required to ensure complete wetting. Paramalingam et al. (2000) determined minimum wetting rates for concentrated milk on flat plates, and they also confirmed that the apparent overall heat transfer coefficient in a commercial evaporator decreases if the flow rate is lower than the required minimum. This would have been due to the reduction in heat transfer area caused by dry patch formation. Morison et al. (2006) used a short evaporator tube to determine the minimum wetting rates for fluids with a wide range of properties. Tube entrance Morison et al. (2006) showed using water and sugar solutions with viscosities up to 100 mPa.s, that the flow rate required to get complete wetting at the tube entrance was nearly always greater than the flow rate required to achieve complete wetting inside the tube (Figure 2a). They used the term “minimum distribution rate” being the equivalent of the minimum wetting rate but applied to the tube entrance. It was clear in the experimentation that sharp edges were more likely to hold up liquid and prevent full wetting. Morison and Sellier (2012) derived an expression to find the optimal shape of the tube entrance (Figure 2b), which was not much different from the currently used radiused edge. Alternative entrance designs with tube inserts have been proposed but these have not been adopted in the dairy industry because of increased difficulty in cleaning such inserts. With the results described above, the conditions required to wet an individual tube are well defined. Figure 2. a) Incomplete wetting at a tube entrance. b) the optimal profile for the tube entrance (Morison and Sellier, 2012). Distribution Systems There is little doubt about the need for even distribution of liquid into all the evaporator tubes. If the flow into any one tube is less than the average it is more likely that fouling will occur. Minton (1986) shows a number of different designs of distributors, but the need for systems to be easily cleaned using clean-in-place (CIP) systems strongly encourages manufacturers to use simple designs. Two current designs are shown in Figure 3; one being a distribution tray with holes in the base and the other with the addition of tubes to allow vapour to pass through. Vapour Liquid Vapour Liquid Figure 3. Cross-section of two possible distributor designs showing the liquid and vapour flows: a) without vapour tubes, b) with vapour tubes. Vapour flows At the top of each evaporator effect there can be vapour flows from flashing or from unequal evaporation between multiple passes in the same effect. These were observed by Broome (2005) to interfere with the liquid flow from distributor plates as shown diagrammatically in Figure 3a. Morison and Broome (2014) showed that vapour tubes are advantageous to minimise interference of the liquid flows by vapour flows. Distributor Holes Holes in the distributor can be arranged in a triangular pattern as shown in Figure 4, or in a hexagonal pattern where each evaporator tube is surrounded by six distributor holes. The second option has twice as many distributor holes with a smaller diameter. If the distributor holes are too large the steady state liquid levels in the distributor trays are low. Liquid levels less than about 20 mm are of concern as good distribution is difficult without sufficient liquid. When the liquid levels are low: changes is the flow rate into the distributor plate have a greater effect of flow from the distributor holes; the disturbance caused by momentum of liquid falling into the distributor plate is greater; the effects of buckling and bowing are greater; the downward velocity of liquid from the distributor hole to the tube sheet is lower so there is less momentum to cause good spreading into the tubes. 1.4 0.94 1.4 0.94 0.7 0.7 0.94 0.7 0.7 0.7 1.4 1.4 0.94 0.7 0.94 0.7 0.94 1.4 1.4 Figure 4. a) Bottom view of a small distributor plate. b) Top view. Small holes are distributor holes: black holes feed one tube, grey holes feed two tubes and while holes feed three tubes. Dash circles indicate the evaporator tube positions. Numbers inside dashed circles indicate the relative flow entering each evaporator tube. Broome (2005) found missing, incorrectly placed, and incompletely drilled holes in distributor plates (Figure 4a). Further, he found that some distributors do not provide all evaporating tubes with an equal flow rate of liquid. Recent practice has been to ignore the importance of “edge effects” so tubes in the outer ring of the tube bundle get overfed while those inside get relatively starved. The effect of this is more significant in calandria with fewer tubes as seen in Figure 4b. Considering the top left evaporator tube in Figure 4b, it can be seen that this is fed by three distributor holes. All the liquid from the top (black) is likely to enter the evaporator tube, but half of the liquid from the left (grey) hole and one third of the liquid from the white hole will enter the tube. Thus the top left evaporator tube received the equivalent of flow from 1.83 distributor holes. In contrast, the central tube will receive one third of the liquid from three distributor holes giving a same flow as one hole. When averaged over all the tubes, the values in Figure 4b were obtained. This effect can be avoided by reducing the diameter of some of the outer distributor holes, e.g., so the black holes in Figure 4b, give ⅓ of the flow of the white holes. Broome (2005) confirmed that tubes with lower flow rates were more inclined to foul excessively and block. He showed that milk concentrate can become so viscous that it stops flowing, and used the term “viscous fouling” to describe this. Buckling of distributor plates Distributor plates can be up to 2 m in diameter and are typically made from 5 mm stainless steel sheet. Without strong reinforcement the plates can easily buckle or bow during the temperature cycling experienced in evaporators. Changes in the horizontal level of the plates of more than 10 mm can lead to variations in flow of more than 10%. The buckling can be measured by inserting the depth probe of a vernier calliper down selected distributor holes. Momentum Liquid feed enters vertically downwards at the top of each pass, so some form of deflection plate is required to minimise the downward momentum of the liquid (Westergaard, 2004, Fig 19). Such momentum has a direct effect of the flow out of any distributor holes below the point of impact. Morison et al. (2006) commented on this and show a multi-stage predistribution system that was developed to minimum momentum effects in a laboratory apparatus. Blockage During operation it is common for some distributor holes, which are typically 6 to 8 mm in diameter, to become blocked. An extreme case is shown in Figure 5. Once blocked, the tubes they feed are more likely to foul. The production of small particles of denatured milk can be linked to cumulative effects of ineffective cleaning or to direct steam injection (Truong et al, 2002). Given the usefulness of direct steam injection for heat treatment, in-line filters are essential to prevent particles from passing downstream and either blocking distributor holes, or adhering to evaporator tube walls. Figure 5. An extreme case of distributor plate blockage Cleaning Cleaning is normally achieved using CIP systems, mostly relying on chemical cleaning with flow through pipes and tubes. Normally liquid flow rates are increased during cleaning to assist wetting. Spray-balls are positioned in open spaces where normal flow is not guaranteed to wet the surfaces. Cleaning failure occurs if: the deposits are too thick to clean in the pre-set cleaning time; cleaning liquids are not distributed equally into the evaporator tubes, for all the same reasons that milk does not get distributed well; or spray balls are not suitably positioned or have insufficient flow. Bird and Fryer (1991) showed that there is an optimal sodium hydroxide concentration for cleaning of whey protein and this has been confirmed for milk by Morison and Thorpe (2002). Jeurnink and Brinkman (1994) found that 1% NaOH was better than 2% concentration for cleaning of milk deposits from an industrial evaporator. They also found that a wetting rate during cleaning of 0.8 kg s-1m-1 was effective with 1% NaOH but a wetting rate of 0.22 kg s1 -1 m was not. Cleaning is often carried out with a reduced vacuum in the evaporator, but the conditions are sufficient to concentrate the cleaning chemicals above the optimal concentrations. Therefore, if cleaning is not effective it is likely that higher flow rates of lower concentration NaOH are required. During cleaning the chemical solution picks up significant quantities of dissolved minerals (Bouman et al. 1988) but according to Mercadé- Prieto et al. (2007) such conditions will reduce the dissolution of -lactoglobulin and is likely to reduce cleaning rates of milk deposits. Inspection The ability to inspect the internals of an evaporator during operation is very useful. It is desirable to be able to view the liquid level on the distributor plate during operation. Using inspection windows Broome (2005) was able to observe distributor plates with excessively low levels and foaming due to effects of high vapour flows. Internal inspection is also required. Bouman et al. (1988) noted: “For a complete analysis of the cleaning procedure a visual inspection before and after cleaning is very helpful to detect where the fouling occurs. Experience in dairy factories has shown that extreme fouling can be caused by faults in the construction of the distribution device or blocked holes in the distribution plate.” After cleaning, all the parts of an evaporator should be clean. A full internal inspection after cleaning is essential to determine complete cleaning. Specific areas of difficulty are the underside of the distributor plate and the bottom tube sheet. However by inspecting a plant after a long run and water rinse but before any chemical cleaning, it is possible to determine which parts are fouled the most. While most operators object to shutting an evaporator down before cleaning, the information gained could be invaluable. Tubes with greater fouling are likely to receive less than the average flow rate of liquid, and the reasons for this need to be found and the problem rectified. If any particles are found to be blocking the distributor plates, the source of these needs to be identified and, if it cannot be eliminated, filters need to be installed. Control At any stage, if the liquid flow rate becomes too low, or if evaporation is excessive, the solids content can increase with the chance of momentary drying on the tubes. The author believes that fouling is most likely to occur when any disturbance causes low flow and/or high solids. The changeover of filters has been observed to cause enough flow disturbance to accelerate fouling and lead to short run times. Once disturbances enter an evaporator it is difficult to control them, but control of the feed flow rate and energy input are easily possible with good instrumentation and controller tuning. The sources of any disturbances need to be determined and eliminated. CONCLUSIONS The industrial experience of Bouman et al. (1988), Broome (2005) and the author has shown that equal and steady liquid distribution within an evaporator is essential for low rates of fouling. The achievement of this requires appropriate calculation of wetting rates, design and fabrication of distributor plates and tube inlets, and the installation of filters and vapour risers. Once the evaporator is installed and operating, inspection of the distribution plates, and both ends of all tubes is essential to identify parts of the evaporator that getting adequate liquid flows, or are not being cleaning well. With such design and inspection, it is likely that falling film evaporators can operate in excess of 20 hours without excessive fouling or bacterial growth. REFERENCES Bird, M. R. and Fryer, P. J. (1991) An experimental study of the cleaning of surfaces fouled by whey proteins, Trans IChemE C Food and Bioproducts Processing 69: 13–21. Bouman, S., Brinkman, D.W., de Jong, P. and Waalewijn, R. (1988) Multistage evaporation in the dairy industry: energy saving, product losses and cleaning, in Preconcentration and Drying of Food Materials, ed S. Bruin, Elsevier Science, Amsterdam. Broome, S.R. (2005) Liquid Distribution and Falling Film Wetting in Dairy Evaporators, ME thesis, University of Canterbury, Christchurch, New Zealand Chen, X.D. and Bala, P. (1998) Investigation of the influences of surface and bulk temperatures upon fouling of milk components onto a stainless steel probe, Proceedings of Fouling and Cleaning in Food Processing ’98, Cambridge, UK. Hartley, D.E. and Murgatroyd, W. (1964) Criteria for the break-up of thin liquid layers flowing isothermally over solid surfaces, International Journal of Heat and Mass Transfer, 7: 1003–1015. Jeurnink, T.J.M. and Brinkman, D.W. (1994) The cleaning of heat exchangers and evaporators after processing milk and whey, Int. Dairy Journal 4: 347-368. Karlsson, E., Gourdon, M., Olausson, L. and Vamling, L. (2013) Heat transfer for falling film evaporation of black liquor up to very high Prandtl numbers, Int. Journal of Heat and Mass Transfer 65: 907–918 Mercadé -Prieto, R., Falconer, R.J., Paterson, W.R. and Wilson, D.I. (2007) Swelling and dissolution of -lactoglobulin gels in alkali, Biomacromolecules 8: 469-476. Minton, P.E. (1986) Handbook of Evaporation Technology, Noyes Publications, Park Ridge, New Jersey. Morison, K.R., and Broome, S.R. (2014) Upward vapour flows in falling film evaporators and implications for distributor design. (submitted for publication) Morison K.R. and Hartel, R.W. (2007) Evaporation and Freeze Drying, Handbook of Food Engineering, 2nd ed, Heldman, D.R., and Lund, D.B. (eds.) CRC Press, Boca Raton, 495-552. Morison, K.R. and Sellier, M. (2012) The optimal profile of weirs for minimum static holdup. International Journal of Multiphase Flow, 39: 245-248. Morison, K.R. & Thorpe, R.J. (2002) Spinning disc cleaning of skim milk and whey protein deposits, Trans IChemE C Food and Bioproducts Processing 80: 319-325 Morison, K.R., Worth, Q.A.G. and O’Dea, N.P. (2006) Minimum wetting and distribution rates in falling film evaporators, Food and Bioproducts Processing 84: 302-310. Paramalingam, S., Winchester, J. and Marsh C. (2000) On the fouling of falling film evaporators due to film breakup, Trans IChemE C Food and Bioproducts Processing, 78: 79–84. Rausch, K.D., Challa, R.K., Zhang, Y.A., Johnston, D.B., Dien, B.S., Singh, V. and Tumbleson, M.E. (2013) Fouling of evaporators in maize processing: developing a fundamental understanding. Proc of the Conf on Heat Exchanger Fouling and Cleaning, June 2013, Budapest, Hungary. Singh, H. (2007) Interactions of milk proteins during the manufacture of milk powders, Lait 87: 413-423. Truong, T, Anema, S, Kirkpatrick, K & Chen, H. (2002) The use of a heat flux sensor for inline monitoring of fouling of non-heated surfaces, Trans IChemE C Food and Bioproducts Processing 80: 260-269.