Interpret installation requirements and plan a custom power plant and

advertisement

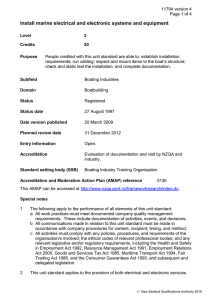

26106 version 1 Page 1 of 3 Interpret installation requirements and plan a custom power plant and power train installation on a vessel Level 5 Credits 6 Purpose People credited with this unit standard are able to interpret requirements for installation of a custom power plant and power train system on a vessel and plan a power plant and power train system installation on a vessel. Subfield Boating Industries Domain Boatbuilding Status Registered Status date 21 May 2010 Date version published 21 May 2010 Planned review date 31 December 2014 Entry information Open. Accreditation Evaluation of documentation and visit by NZQA and industry. Standard setting body (SSB) Boating Industry Training Organisation Accreditation and Moderation Action Plan (AMAP) reference 0136 This AMAP can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Special notes 1 For this unit standard competence may be demonstrated by leading and supervising an actual installation or for a simulated situation using a set of plans as a basis for planning. 2 Definitions Custom power plant and power train – power plant and drive train in a custom built vessel greater than 15m in length. Job requirements – requirements that may or may not be specified but require correct choices to achieve including: following safety and workplace procedures and meeting generally accepted trade practice standards. New Zealand Qualifications Authority 2016 26106 version 1 Page 2 of 3 3 References – Information about classification societies can be found at http://www.iacs.org.uk/. – European Union (EU) Recreational Craft Directive (94/25/EC)http://ec.europa.eu/enterprise/maritime/maritime_regulatory/directive_9 425.htm. – US Coastguard http://www.uscgboating.org. – National Standard for Commercial Vessels (Australia) http://www.nmsc.gov.au. – ISO standards http://www.iso.org. Elements and performance criteria Element 1 Interpret requirements for installation of a power plant and power train system on a vessel. Performance criteria 1.1 Location of power plant and power train and associated equipment is determined and verified in accordance with vessel plans and specifications. 1.2 Engine room construction elements that are relevant to power plant and power train mounting are identified and verified in accordance with vessel plans and specifications. 1.3 Installation criteria for power plant, power train systems and associated equipment are determined in accordance with manufacturer’s specifications and vessel plans and specifications. Range 1.4 includes but is not limited to – exhaust system, water inlet, cooling, coupling, alignment, bearings, strut support, stern tube, gland/seal installation, engine mounts, electrical system, engine speed control system, gearbox mounting, gearbox control system, shafting, prop clearances, sound insulation, ventilation system. System corrosion protection requirements are determined in accordance with component material types and layout. Element 2 Plan a power plant and power train system installation on a vessel. Performance criteria 2.1 System is sourced in accordance with vessel contract specifications. Range 2.2 custom made and vendor sourced components. Component warranty conditions are checked for compliance with job requirements. New Zealand Qualifications Authority 2016 26106 version 1 Page 3 of 3 2.3 Installation is planned in terms of order and stages of work. Range 2.4 includes but is not limited to – exhaust system, water inlet, cooling, coupling, alignment, bearings, strut support, stern tube, gland/seal installation, engine mounts, electrical system, engine speed control system, gearbox mounting, gearbox control system, shafting, prop clearances, sound insulation, ventilation system. Installation planning includes identification of input required by different trades and contributors. Range may include but is not limited to – boatbuilders, pipework installers, ticketed electrical installers, design engineers. 2.5 Installation plan includes commissioning and documentation in accordance with system specifications. 2.6 Installation is planned to avoid potential conflict with other systems. Range 2.7 may include but is not limited to – electrical, refrigeration, air conditioning, hydraulic. Installation plan includes compliance with relevant rules. Range may include but is not limited to – class society rules, maritime rules, company rules, designer specifications, resolving conflict between rules when conflict exists. Please note Providers must be accredited by NZQA, or an inter-institutional body with delegated authority for quality assurance, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be accredited by NZQA before they can register credits from assessment against unit standards. Accredited providers and Industry Training Organisations assessing against unit standards must engage with the moderation system that applies to those standards. Accreditation requirements and an outline of the moderation system that applies to this standard are outlined in the Accreditation and Moderation Action Plan (AMAP). The AMAP also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the Boating Industry Training Organisation info@bia.org.nz if you wish to suggest changes to the content of this unit standard. New Zealand Qualifications Authority 2016