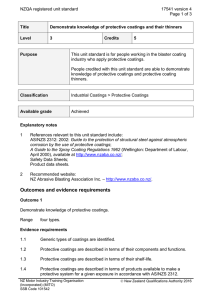

NZQA registered unit standard 17539 version 4 Page 1 of 5

advertisement

NZQA registered unit standard 17539 version 4 Page 1 of 5 Title Describe and apply wet protective coatings Level 4 Credits 25 Purpose People credited with this unit standard are able to: describe and compare wet protective coatings and methods; calculate mixing ratios and application quantities for wet protective coatings; prepare and mix multiple component wet protective coatings; apply wet protective coatings to a range of surfaces; and maintain, clean, and store wet protective coating equipment. Classification Industrial Coatings > Protective Coatings Available grade Achieved Entry information Critical health and safety prerequisites Unit 17547, Demonstrate knowledge of health and safety for blaster coating operations, or demonstrate equivalent knowledge and skills. Explanatory notes 1 Documents relevant to this unit standard include: AS/NZS 2312: 2002: Guide to the protection of structural steel against atmospheric corrosion by the use of protective coatings; Safety Data Sheets; Product data sheets and labels. 2 When applying coatings containing isocyanate, an air-fed respirator must be worn in accordance with Approved Code of Practice for the Safe Use of Isocyanates (Wellington: Occupational Safety and Health Service, Department of Labour, 1994). 3 Definitions Company procedures refer to documented methods for performing work activities and include health and safety, environmental, and quality management requirements. They may refer to manuals, codes of practice, manufacturer’s instructions, or policy statements. Job specifications may include written and oral direction for specific tasks, standard procedures documented in company quality manuals, and technical procedures for specific materials or equipment. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 17539 version 4 Page 2 of 5 Outcomes and evidence requirements Outcome 1 Describe and compare wet protective coatings and methods. Evidence requirements 1.1 Wet protective coatings are described in terms of their properties and characteristics. Range 1.2 Methods of application of wet protective coatings are identified and described in terms of coating type. Range 1.3 epoxy, urethane, two-pack acrylic, zinc and zinc silicate, alkyd, vinyl, chlorinated rubber. Wet protective coatings are compared in terms of relative costs and service life. Range 1.4 epoxy, urethane, two-pack acrylic, zinc and zinc silicate, alkyd, vinyl, chlorinated rubber. epoxy, urethane, two-pack acrylic, zinc and zinc silicate, alkyd, vinyl, chlorinated rubber. The compatibility and incompatibility of wet protective coatings with different substrates is determined and explained; and surface preparation requirements for compatible coatings are described in accordance with coating manufacturer’s instructions. Range three compatible coatings, three incompatible coatings; substrates may include – steel, stainless steel, galvanised, aluminium, concrete, metal spray. Outcome 2 Calculate mixing ratios and application quantities for wet protective coatings. Evidence requirements 2.1 Surface areas are calculated from given physical dimensions of flat and curved surfaces. 2.2 The quantity of wet protective coating required for a given job is estimated in accordance with job specifications and the product data sheet. 2.3 Quantities of product are calculated from given mixing or thinning ratios in accordance with manufacturer’s instructions. 2.4 Coating quantities are calculated from given coating application rates to achieve prescribed thickness in accordance with job specifications. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 17539 version 4 Page 3 of 5 Outcome 3 Prepare and mix multiple component wet protective coatings. Range mix for three different application methods. Evidence requirements 3.1 Personal protective clothing for mixing wet protective coatings is fitted and worn in accordance with company procedures. 3.2 Pre-treatment processes for wet protective coatings are carried out in sequence in accordance with product data sheet and job specifications. 3.3 Mixing procedures for wet protective coatings are described in accordance with instructions on product data sheet and product label. 3.4 Wet protective coating containers are opened in accordance with company procedures, Safety Data Sheet, and product data sheet. 3.5 Wet protective coatings are mixed and/or thinned in accordance with manufacturer’s instructions. 3.6 Wet protective coating is prepared for application in accordance with manufacturer’s instructions. Outcome 4 Apply wet protective coatings to a range of surfaces. Range surfaces may include but are not limited to – concrete, timber, carbon steel, zinc, galvanised surfaces, aluminium, stainless steel, plastics; a minimum of three types of surfaces are to be coated and each coating method relevant to that coating is to be demonstrated. Evidence requirements 4.1 Job specifications, including products and equipment to be used, are confirmed in accordance with company procedures. 4.2 Personal protective clothing and equipment for applying wet protective coatings are fitted and worn in accordance with manufacturer’s instructions and company procedures. 4.3 Spray equipment, air service units, hoses, spray gun, and nozzle are set up and wet protective coating is applied in accordance with job specifications and company procedures. Range methods may include but are not limited to – airless, high volume low pressure, pressure pot, conventional spray. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 17539 version 4 Page 4 of 5 4.4 Damaged or flawed wet protective coating is touched up to meet job specifications. 4.5 Drying and/or curing times for wet protective coatings are adhered to in accordance with product data sheet and conditions. times – job specified, taking account of atmospheric conditions. Range 4.6 Wet protective coating meets quality requirements for surface finish, measurement of coating thickness, and colour conformity in accordance with job specifications. Outcome 5 Maintain, clean, and store wet protective coating equipment. Evidence requirements 5.1 Wet protective coating equipment is checked for maintenance and is repaired and/or reported for repair in accordance with company procedures. 5.2 Wet protective coating equipment is cleaned, shut down, and stored in accordance with manufacturer’s instructions and company procedures. equipment includes but is not limited to – brushes, rollers, spray equipment. Range Planned review date 31 December 2019 Status information and last date for assessment for superseded versions Process Version Date Last Date for Assessment Registration 1 28 August 2000 31 December 2012 Review 2 20 November 2006 31 December 2013 Review 3 18 October 2012 31 December 2016 Review 4 16 April 2015 N/A Consent and Moderation Requirements (CMR) reference 0114 This CMR can be accessed at http://www.nzqa.govt.nz/framework/search/index.do. Please note Providers must be granted consent to assess against standards (accredited) by NZQA, before they can report credits from assessment against unit standards or deliver courses of study leading to that assessment. Industry Training Organisations must be granted consent to assess against standards by NZQA before they can register credits from assessment against unit standards. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016 NZQA registered unit standard 17539 version 4 Page 5 of 5 Providers and Industry Training Organisations, which have been granted consent and which are assessing against unit standards must engage with the moderation system that applies to those standards. Requirements for consent to assess and an outline of the moderation system that applies to this standard are outlined in the Consent and Moderation Requirements (CMR). The CMR also includes useful information about special requirements for organisations wishing to develop education and training programmes, such as minimum qualifications for tutors and assessors, and special resource requirements. Comments on this unit standard Please contact the NZ Motor Industry Training Organisation (Incorporated) (MITO) info@mito.org.nz if you wish to suggest changes to the content of this unit standard. NZ Motor Industry Training Organisation (Incorporated) (MITO) SSB Code 101542 New Zealand Qualifications Authority 2016