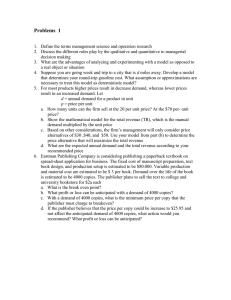

Chapter 13 - Aggregate Planning

advertisement

Chapter 13 – Aggregate Planning Operations Management by R. Dan Reid & Nada R. Sanders 2nd Edition © Wiley 2005 PowerPoint Presentation by R.B. Clough - UNH What is Aggregate Planning? Aggregate planning is intermediaterange (2 to 12 months) capacity planning useful in particular for organizations that experience seasonal or other fluctuation in demand. The goal of aggregate planning is to effectively utilize the organization’s resources to satisfy expected demand. The Role of the Aggregate Plan The Concept of Aggregation Aggregate planning is a “big picture” approach that does not focus on individual products or services. Instead, the focus is on groups of similar products of an entire product line. Examples: Total number of bikes produced Total number of customers served Responses to Demand Fluctuations Demand-based options are intended to alter (smooth) the pattern of the demand. Capacity-based options to alter capacity to better match the demand. Demand-based Options Finished goods inventories: Back orders & lost sales: Delay delivery or allow demand to go unfilled when demand exceeds capacity Shift demand to off-peak times: To meet anticipate high demand Proactive marketing: pricing, promotions Create new (complementary) demand Capacity-based Options Overtime: Short-term option Idle time: Short-term option Pay workers a premium to work longer hours Slow the production rate or send workers home early (lowers labor productivity, but doesn’t tie up capital in finished good inventories) Subcontracting: Medium-term option Hire & fire workers: Long-term option Change the size of the workforce Aggregate Plan Strategies Level plans: Use a constant workforce & produce similar quantities each time period. Use inventories & backorders to absorb demand peaks & valleys Chase plans: Minimize finished good inventories by trying to keep pace with demand fluctuations Hybrid Strategies Use a combination of options: Build-up inventory ahead of rising demand & use backorders to level extreme peaks Layoff or furlough workers during lulls Subcontract production or hire temporary workers to cover short-term peaks Reassign workers to preventive maintenance during lulls Developing Aggregate Plan Choose the basic strategy: Level, chase, or hybrid Determine the production rate: Level plan with back orders: rate = average demand over the planning horizon Level plan without back orders: rate is set to meet all demand on time Chase plan: assign regular production, amount of overtime & subcontracted work to meet demand Developing the Aggregate Plan Calculate the size of the workforce needed Calculate period-to-period inventory levels, shortages, expected hiring & firings, and overtime Calculate period-by-period costs, then sum for total costs of the plan Evaluate the plan’s impact on customer service and human resource issues Evaluating Alternative Plans Level strategy plan Chase strategy plan Aggregate Planning Example Period Demand 1 3000 Beginning Inventory Beginning Workforce Labor Standard (units/worker) 2500 18 250 Costs Regular Time Labor Cost Overtime/Subcontracting Inventory Holding Cost Backorders Hiring Layoff Cost Per Unit $9.60 $14.40 $5.00 $7.50 $500.00 $750.00 2 6000 3 2000 4 1500 5 4000 6 5500 7 8500 Aggregate Planning Template Aggregate Production Planning Costs Regular Time Labor Cost Overtime/Subcontracting Inventory Holding Cost Backorders Hiring Layoff Beginning Inventory Beginning Workforce Labor Standard (units/worker) Cost Per Unit Total Units Total Cost Total Costs Period Demand Cumulative Demand Net Cumulative Demand Production/Inventory Planning Production Cumulative Production Inventory (Excess Units) Backorders (Units Short) Capacity Planning Workers Hired Workers Layed Off Workforce Available Regular Time Capacity (units) Overtime/Subcontracting (units) Total Production Capacity (units) 1 2 3 4 5 6 7 8 Level Strategy Aggregate Production Planning Costs Regular Time Labor Cost Overtime/Subcontracting Inventory Holding Cost Backorders Hiring Layoff Cost Total Total Per Unit Units Cost $9.60 28000 $268,800 $14.40 0 $0 $5.00 25000 $125,000 $7.50 0 $0 $500.00 0 $0 $750.00 2 $1,500 Total Costs $395,300 Beginning Inventory Beginning Workforce Labor Standard (units/worker) 2500 18 250 Period Demand Cumulative Demand Net Cumulative Demand 1 3000 3000 500 2 6000 9000 6500 3 2000 11000 8500 4 1500 12500 10000 5 4000 16500 14000 6 5500 22000 19500 7 8500 30500 28000 Production/Inventory Planning Production Cumulative Production Inventory (Excess Units) Backorders (Units Short) 4000 4000 3500 0 4000 8000 1500 0 4000 12000 3500 0 4000 16000 6000 0 4000 20000 6000 0 4000 24000 4500 0 4000 28000 0 0 Capacity Planning Workers Hired Workers Layed Off Workforce Available Regular Time Capacity (units) Overtime/Subcontracting (units) Total Production Capacity (units) 0 2 16 4000 0 4000 0 0 16 4000 0 4000 0 0 16 4000 0 4000 0 0 16 4000 0 4000 0 0 16 4000 0 4000 0 0 16 4000 0 4000 0 0 16 4000 0 4000 8 Non-Financial Criteria Operations perspective: Human resources perspective: Smooth & even flow is easy to manage Nobody hired or fired, no overtime or furloughs, so employee morale should be fine Marketing perspective: All demand met, so no customer service issues Chase Strategy Aggregate Production Planning Costs Regular Time Labor Cost Overtime/Subcontracting Inventory Holding Cost Backorders Hiring Layoff Cost Total Total Per Unit Units Cost $9.60 28000 $268,800 $14.40 0 $0 $5.00 0 $0 $7.50 0 $0 $500.00 50 $25,000 $750.00 34 $25,500 Total Costs $319,300 Beginning Inventory Beginning Workforce Labor Standard (units/worker) 2500 18 250 Period Demand Cumulative Demand Net Cumulative Demand 1 3000 3000 500 2 6000 9000 6500 3 2000 11000 8500 4 1500 12500 10000 5 4000 16500 14000 6 5500 22000 19500 7 8500 30500 28000 Production/Inventory Planning Production Cumulative Production Inventory (Excess Units) Backorders (Units Short) 500 500 0 0 6000 6500 0 0 2000 8500 0 0 1500 10000 0 0 4000 14000 0 0 5500 19500 0 0 8500 28000 0 0 Capacity Planning Workers Hired Workers Layed Off Workforce Available Regular Time Capacity (units) Overtime/Subcontracting (units) Total Production Capacity (units) 0 16 2 500 0 500 22 0 24 6000 0 6000 0 16 8 2000 0 2000 0 2 6 1500 0 1500 10 0 16 4000 0 4000 6 0 22 5500 0 5500 12 0 34 8500 0 8500 8 Non-Financial Criteria Operations perspective: Human resources perspective: Can operations ramp up & back down this quickly? Much more difficult to accomplish Will employees tolerate being hired & fired so rapidly? What about training & learning curve issues? Marketing perspective: All demand is met (assuming no strikes) A Minimum Cost Plan (Hybrid Strategy) Aggregate Production Planning Cost Total Total Costs Per Unit Units Cost Regular Time Labor Cost $9.60 28000 $268,800 Overtime/Subcontracting $14.40 0 $0 Inventory Holding Cost $5.00 2750 $13,750 Backorders $7.50 0 $0 Hiring $500.00 28 $14,000 Layoff $750.00 12 $9,000 Total Costs $305,550 Beginning Inventory Beginning Workforce Labor Standard (units/worker) 2500 18 250 Period Demand Cumulative Demand Net Cumulative Demand 1 3000 3000 500 2 6000 9000 6500 3 2000 11000 8500 4 1500 12500 10000 5 4000 16500 14000 6 5500 22000 19500 7 8500 30500 28000 Production/Inventory Planning Production Cumulative Production Inventory (Excess Units) Backorders (Units Short) 3250 3250 2750 0 3250 6500 0 0 2000 8500 0 0 1500 10000 0 0 4000 14000 0 0 5500 19500 0 0 8500 28000 0 0 Capacity Planning Workers Hired Workers Layed Off Workforce Available Regular Time Capacity (units) Overtime/Subcontracting (units) Total Production Capacity (units) 0 5 13 3250 0 3250 0 0 13 3250 0 3250 0 5 8 2000 0 2000 0 2 6 1500 0 1500 10 0 16 4000 0 4000 6 0 22 5500 0 5500 12 0 34 8500 0 8500 8 Aggregate Planning Bottom Line The Aggregate plan must balance several perspectives Costs are important but so are: Customer service Operational effectiveness Workforce morale A successful AP considers each of these factors Service Planning Issues Intangible products can’t be inventoried Possible approaches: Try to proactively shift demand away from peaks Use overtime or subcontracting to handle peaks Allow lost sales Chapter 13 HW Assignment Problems 1 – 5, 10 -12.