Whiteland Village Mary Longenecker Structural Option Senior Thesis

Whiteland Village

Mary Longenecker

Structural Option

Senior Thesis

August 7, 2007

Whiteland Village

Outline

• Introduction

• Criteria for Redesign

• Lateral Redesign

– Staggered Truss

– Partially Restrained

Composite Connections

• Construction Management

Issues

• Existing Envelope

Analysis

• Conclusions

Whiteland Village

Retirement Community

Exton, Pennsylvania

1,320,000 sq. ft.

$100-150 million

Design-Build

Dates of Construction

Nov. 2006 - Nov. 2008

Architects:

Dever Architects (Residences)

HLM Design (Commons)

Structural Engineers:

Baker, Ingram & Associates

Construction Managers:

Paul Risk Associates, Inc.

HVAC:

Madsen, Inc.

Electrical:

Meadow Valley Electric

Whiteland Village

Existing Systems

• HVAC

– Central Exhaust System using Energy Wheel

– Chilled Water Cooling

– Gas Hot Water Heating

• Fire Protection

– Wet Sprinkler System

• Electrical

– 208Y/120V from (1) 5kV Transformer

– Onsite Co-generation Plant

Whiteland Village

Existing Structural System

Whiteland Village

• Lateral System

– 10” CMU Shearwalls

– 10” Thick Concrete Shearwalls

Existing Structural System

• Floor System

– 8” Untopped Hollow

Core Precast Plank

– Spanning 30 ft.

– Can be considered a rigid diaphragm

Whiteland Village

Alternate Design Considerations

• Ease of future renovations

• Maximum 1’-8” structural depth

• Constructability

• Cost

• Floor vibration

• Fire protection

Whiteland Village

Staggered Truss

• Full story trusses

– Span transverse width

– Alternate floors

• Advantageous in long and narrow buildings

Whiteland Village

Staggered Truss Alternate

Whiteland Village

Staggered Truss Alternate

Whiteland Village

Truss T1

Staggered Truss Alternate

Whiteland Village

Truss T2

Staggered Truss Alternate

• Floor System

– 8” Untopped Hollow-Core Precast Plank

• Design Base Shear = 462 k

– R = 3 for overall system

– T = Cu * Ta

Whiteland Village

Staggered Truss Alternate

Axial Force in Truss due to Gravity Loads (k)

Whiteland Village

Staggered Truss Alternate

Axial Force in Truss due to Lateral Loads (k)

Whiteland Village

Staggered Truss Alternate

Columns:

W10x100 A992

Diagonals and Verticals:

HSS 8x6x5/8 A500 GrB

Chords:

W10x77 to W10x112 A992

Truss T1

Whiteland Village

Staggered Truss Alternate

Slotted HSS to Gusset

Plate Connection

Details:

Weld Length: 20”

Width: 3/8”

Plate Thickness: 1/2”

Whiteland Village

Staggered Truss Alternate

Foundations

Truss Columns

7’x7’x1’-10” spread footing with (6) #7 bars ea. way

Gravity Columns

4’x4’x1’ spread footing with (4) #5 bars ea. way

Typical Detail of Column Footing

Whiteland Village

Partially Restrained Composite

Connections

• Type 3 connections

– Used with steel frame and composite floor

• Reinforcing in the slab used to create top portion of moment connection

• Shear resistance from seat angle at bottom of connection

Whiteland Village

Partially Restrained Composite

Connections

Whiteland Village

Typical Detail of PRCC

Partially Restrained Composite

Connection Alternate

Whiteland Village

Partially Restrained Composite

Connection Alternate

Whiteland Village

Braced Frame in NS Direction

Partially Restrained Composite

Connection Alternate

Whiteland Village

Braced Frame in EW Direction

Partially Restrained Composite

Connection Alternate

• Floor System Determination

– Using Floor Vibration Serviceability

• 1 1/2” Composite Deck with 5.5” Total

Slab Thickness

• Design Lateral Load = 431 k

– R = 3

– T = Cu * Ta

Whiteland Village

Partially Restrained Composite

Connection Alternate

Frame

NS

EW

Beam Location Connection Beam and Studs Mu (ftk) I

LB

(in^4)

Typ Bay Floor PIN-PIN

Int. Bay Floor PIN-PIN

Ext. Bay Floor PIN-PIN

W21x44 (14)

W16x40 (16)

W16x40 (16)

397

277

277

1420

886

886

• Analysis determined PRCC type connections not warranted in braced frame layout

• Structural depth greater than 1’-8” limit

• Condominium layouts would require changes to allow for bracing

Whiteland Village

Construction Management Issues

• Existing Lateral

System Cost:

$363,000

• Staggered Truss

System Cost:

$610,000

• Existing system more labor-intensive

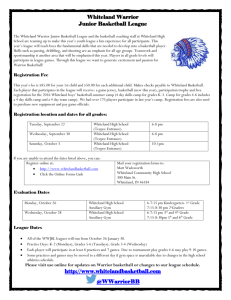

Whiteland Village

Material

CMU Walls

Conc Walls

Scaffold

Conc Ftgs

Total

Adjusted Total

Total Cost

106236

63120

60255

43285

272896

362618

Existing Lateral System Cost

Material

STL Cols

Fireproofing

HSS Bracing

STL Beams

Conc Ftgs

Total Cost

Adjusted Total

Total Cost

36786

40582

96941

279590

5356

459255

610246

Staggered Truss System Cost

Existing Envelope Analysis

Concerns:

• Drainage

• Drip edge

• Moisture Penetration

Whiteland Village

Existing Envelope Analysis

Roof wells for mechanical units

Whiteland Village

Existing Envelope Analysis

Whiteland Village

Existing Envelope Analysis

• Recommendations

– Add drainage cavity

– Extend drip edge

– Keep existing detailing for mechanical wells

– Onsite checks to ensure detailing complete

Whiteland Village

Conclusions

• Staggered truss is a feasible structural alternate

– Allows for ease of renovation

– More costly system

• Partially restrained composite connections are not feasible

• Envelope details should be reworked to prevent bulk water penetration

Whiteland Village

Acknowledgements

Thanks to the following individuals for their assistance throughout my project:

– Dr. Andres LePage

– Andreas Phelps

– The entire AE Department Faculty and Staff

– Larry Baker and the entire staff of Baker, Ingram & Associates

– John Beers of Paul Risk Associates Inc.

– Partners of Whiteland Village

Special thanks to my friends and family

Whiteland Village

Whiteland Village

Questions