Rotorcraft Fuselage Drag Study using OVERFLOW-D2 on a Linux Cluster

advertisement

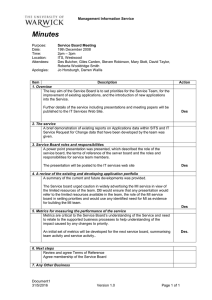

Project Number : PS 7.1 Rotorcraft Fuselage Drag Study using OVERFLOW-D2 on a Linux Cluster PI: Associate Professor EPN Duque tel : 928-523-5842 www.cet.nau.edu/~end2 Northern Arizona University Graduate Assistant/Research Engineer: Nathan Scott 2004 RCOE Program Review May 4, 2004 1 College of Engineering and Natural Sciences Mechanical Engineering Department Background/ Problem Statement: • Evaluate fuselage force and moment prediction capability of the OVERFLOW2 and OVERFLOW-D • Utilize cost effective computer systems 2 College of Engineering and Natural Sciences Mechanical Engineering Department Technical Barriers or Physical Mechanisms to Solve : • Appropriate grid generation over specific aircraft • Lift and drag forces over simplified shapes such as prolate spheroid 3 • Grid sensitivity studies required • Unsteady flow capturing on bluff bodies College of Engineering and Natural Sciences Mechanical Engineering Department Task Objectives: Using the OVERFLOW code • Evaluate drag prediction on a prolate spheroid • Evaluate drag prediction on a helicopter fuselage • Evaluate and document effects of grid resolution • Evaluate turbulence models upon predictions. • 1-eqn, 2-eqn, DES • Compare results with Penn State Methods 4 College of Engineering and Natural Sciences Mechanical Engineering Department Approaches: • OVERFLOW2 Code • Grid Generation • Near body grid refinement in boundary layer • Grid adaptation in the field for vortical flow • Turbulence models • Baldwin-Barth • Spalart-Almaras • k-w • Mentor-SST • include Detached Eddy Simulation (DES) 5 College of Engineering and Natural Sciences Mechanical Engineering Department Overview Explain S-A and SST Detached Eddy simulation Discuss DES Implementation in OVERFLOW Circular Cylinder results 6:1 Prolate Spheroid results 6 College of Engineering and Natural Sciences Mechanical Engineering Department Experimental Data Virginia Tech Stability Wind Tunnel – Wetzel, Simpson, Ahn 1.37 m 6:1 Prolate Spheroid Free stream conditions – α=20º, Re=4.2E6, Ma=0.16 Coefficient of Pressure (Cp), Skin Friction (Cf)from Wetzel Dissertation U/u*, y+ from Simpson’s Website 7 College of Engineering and Natural Sciences Mechanical Engineering Department CFD Methodology Reynolds Averaged Navier-Stokes Equations – – – – OVERFLOW-D code developed at NASA and Army Uses detailed overset grids Allows for detailed geometry definition Captures viscous effects such as unsteady flow separation OVERFLOW2 used for turbulence model study and Implementation of DES – – – – 8 Scalar penta-diagonal scheme 1st order difference in time 2nd or 4th order RHS (OVERFLOW2) 2nd and 4th order central difference dissipation terms College of Engineering and Natural Sciences Mechanical Engineering Department Detached Eddy Simulation First Formulated by Spalart as a modification to S-A model in 1997. Later generalized to any model by Strelets in 2001. First step was to modify the S-A model 9 College of Engineering and Natural Sciences Mechanical Engineering Department S-A-DES formulation Change distance to wall in S-A model dw to – Ĩ=min(dw,CDES∆) – ∆ is the maximum of the grid spacing in three dimensions- ∆=max(δX, δY, δZ) – CDES=0.65 10 College of Engineering and Natural Sciences Mechanical Engineering Department k-w-SST-DES Formulation Change k-transport source term: ρβ*kω=ρk3/2/Ĩ – Ĩ=min(lk-ω,CDES∆) – lk-ω=k1/2/(β*ω) – ∆ is the maximum of the grid spacing in three dimensions- ∆=max(δX, δY, δZ) – CDES=(1-F1) Ck-ε+F1 Ck-ω – Ck-ε=0.61, Ck-ω=0.78 • At equilibrium reduces to an algebraic mixing-length Smagorinski type model. 11 College of Engineering and Natural Sciences Mechanical Engineering Department Implementation in OVERFLOW Determine grid cell edge lengths in J,K,L directions – One sided difference at boundaries – Central difference otherwise Background Cartesian Grids - DES always enabled 12 College of Engineering and Natural Sciences Mechanical Engineering Department Circular Cylinder Test Case Re=140,000, Ma=0.2 Fully Turbulent S-A, S-A-DES, SST-DES turbulence models 7.6 million grid points – Near body 181 by 60 by 99 – Background 426 by 61 by 252 – Off Body grid resolution 0.05 the diameter – H type block grid extends 10 diameters – 2 total grids Methods – 4th central difference in space – 1st order Beam-Warming in time 13 Inviscid wall Boundary Conditions College of Engineering and Natural Sciences Mechanical Engineering Department Other DES work with Cylinder Travin, A, Shur, M, Strelets, M, Spalart, P – Re = 50,000 and 140,000 – Laminar Separation » Laminar Separation » LES in Background – Turbulent Separation » Run Fully Turbulent » Compares to higher Re 14 College of Engineering and Natural Sciences Mechanical Engineering Department Iso-surface visualization comparison Circular Cylinder Travin-DES OVERFLOW URANS (Not Unsteady Yet) 15 College of Engineering and Natural Sciences Mechanical Engineering Department OVERFLOW S-A-DES OVERFLOW k-w-SST-DES Unsteady Pressure coefficient for 1 drag cycle 1.5 Average 1 drag cycle Exp-Nunen-Re=7.6 E6 Exp-Roshko-8.6 E6 Scatter 1 drag cycle 1 0.5 Cp 0 -0.5 -1 -1.5 -2 -2.5 0 16 20 40 60 80 100 120 angle from windward side College of Engineering and Natural Sciences Mechanical Engineering Department 140 160 180 Average Pressure coefficient for 1 drag cycle 1.5 SA-DES SA-RANS DES-Travin Exp-Nunen-Re=7.6 E6 Exp-Roshko-8.6 E6 1 0.5 Cp 0 -0.5 -1 -1.5 -2 0 17 20 40 60 80 100 120 angle from windward side College of Engineering and Natural Sciences Mechanical Engineering Department 140 160 180 Conclusions from Circular Cylinder S-A DES in OVERFLOW looks promising – More fine scale resolution – Cross Flow on “2-D” cases – Comparable comparisons to Experimental Data k-w-SST DES in OVERFLOW also looks promising – SST has been shown to approximate separation better so more desirable in shear layer – More verification needs to be done 18 College of Engineering and Natural Sciences Mechanical Engineering Department 6:1 Prolate Spheroid Test Case Re=4,200,000, Ma=0.16 Trip to Turbulence at x/L=0.2 S-A, S-A-DES, SST-DES turbulence models 7 million grid points – Near body 361 by 310 by 45 – First off body Grid spacing 0.08 the length – Remaining off body grids reduce in resolution by half – Off body grids extent to 10 times the length – 61 Total grids – Grid shown to be convergent in Previous Study Methods – 4th central difference in space – 1st order Beam-Warming in time 19 College of Engineering and Natural Sciences Mechanical Engineering Department Other DES work with 6:1 Prolate Spheroid Rhee, S. H. and Hino,T. – Re = 4,200,000 Ma=0,16 – Run Steady and Unsteady – Showed under prediction of Lift 20 College of Engineering and Natural Sciences Mechanical Engineering Department Surface Skin Friction and vorticty contour comparison for 6:1 Spheroid S-A SST 21 College of Engineering and Natural Sciences Mechanical Engineering Department S-A DES SST DES Comparison Of Lift and Pitching Moment for 6:1 Spheroid All of the models fall with error for Pitching Moment All of the models under predict lift 22 College of Engineering and Natural Sciences Mechanical Engineering Department Lift Pitching Moment Experiment 0.61±0.03 0.23±0.04 SA 0.45 0.24 SST 0.48 0.23 S-A-DES 0.42 0.25 SST-DES 0.45 0.24 Rhee & Hino 0.48 0.24 Axial Surface Pressure at x/L=0.77 0 -0.05 -0.1 Exp S-A SST S-A DES SST DES Cp -0.15 -0.2 -0.25 -0.3 -0.35 0 23 20 40 60 80 100 120 140 160 180 angle from windward side College of Engineering and Natural Sciences Mechanical Engineering Department Velocity Profile at x/L=0.77 and 150º from Windward side 25 20 U/u* 15 10 S-A DES SST DES S-A SST Exp 5 0 0 10 10 1 10 2 yplus 24 College of Engineering and Natural Sciences Mechanical Engineering Department 10 3 10 4 10 5 Axial Skin Friction at x/L=0.77 10 9 8 Cf 7 6 5 4 3 2 1 0 25 Exp S-A SST S-A DES SST DES 20 40 60 80 100 120 140 160 180 angle from windward side College of Engineering and Natural Sciences Mechanical Engineering Department Streamlines on Leeside 26 College of Engineering and Natural Sciences Mechanical Engineering Department 6:1 Spheroid Conclusions 27 DES shown to work with overset grids DES did not improve integrated forces Skin friction remained the same Surface pressure showed slight improvement Velocity profiles remained the same close to surface y+<10 Velocity profiles improved farther away from surface y+>100 College of Engineering and Natural Sciences Mechanical Engineering Department Accomplishments Summer work with Roger Strawn and Mark Potsdam at Ames Presented at AIAA 43rd Aerospace Sciences Meetings. 28 College of Engineering and Natural Sciences Mechanical Engineering Department Future Work Grid Refinement Study on 6:1 Prolate spheroid and DES New research engineer, explore new LES Apply DES and LES to helicopter fuselage 29 College of Engineering and Natural Sciences Mechanical Engineering Department