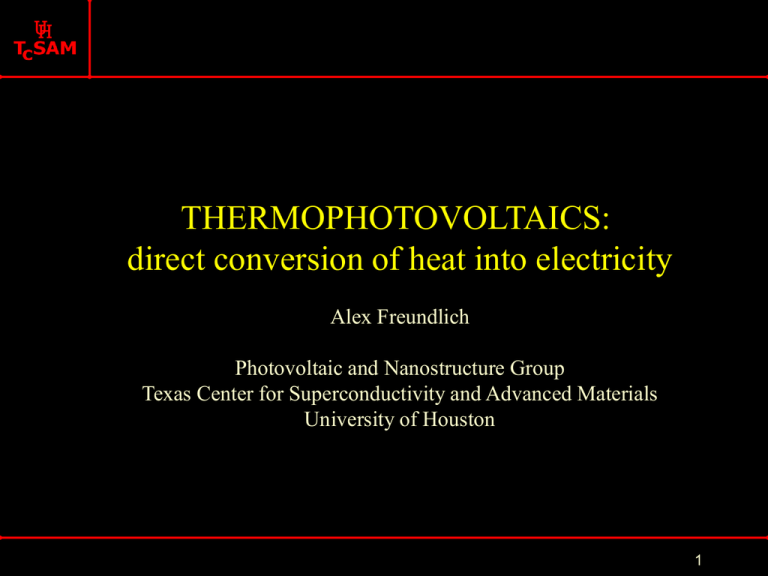

Alex Freundlich

advertisement

THERMOPHOTOVOLTAICS: direct conversion of heat into electricity Alex Freundlich Photovoltaic and Nanostructure Group Texas Center for Superconductivity and Advanced Materials University of Houston 1 Thermophotovoltaics (TPV) Photons emanating from a hot emitter are converted by a PV cell (IR sensitive solar cell) Emitter temperature :~900-1500oC 2 Solar PV /TPV Solar PV emitter (sun)-PV cell distance 150 millions km Sun= black body at 5800 K, output power 0.01-0.03 W/cm2 TPV : emitter - PVcell distance few cm TPV emitters1200<T<1800 K, 1<PTPV<30 W/cm2 3 As for solar PV •higher bandgap favor high operating voltage/low current •Lower bandgap favor high current output but a low voltage operating voltage Ideal bandgap for TPV cell is a function of the emitter spectrum 4 Efficiency/0utput power density Assuming loss of transparency loss photons Efficiency vs bandgap Output power vs bandgap 5 Converter Materials Suitable band gap (~0.4-0.6eV) Existing converter materials: InGaAs/InP InGaAsSb/GaSb InAs 6 Applications/ advantages 7 TPV for military applications Advantages : •Low IR and acoustic signature (favors stealth operation) •High specific power (increased troop mobility) •TPV device degrade graciously (mitigates catastrophic failures) Applications: •Diesel/propane fuel operated TPV (0.5-1.5 KW compact portable power generation units ) •Electric power for naval applications 8 TPV for automotive applications “Viking 29 “concept car developed by Univ. of Washington and JX Crystals •High power density •Silent (no moving parts) 9 Co-generation of electricity residential/industrial waste heat recovery •Example use of TPV for self supported /self regulated heating system (pilot system test in Switzerland) 10 Co-generation for remote and leisure markets JX Crystals, Inc. the fuel is already burned for heat and the electricity to charge batteries is "free". 11 TPV for Deep space exploration Radioisotope TPV • PuO2 GPHS heat source • Solid selective emitter • MIM PV array • Target h of 20% Advantages: •No moving parts •Degradation if any gradual •compact •Three time more efficient than existing TE technology 12 Recycling unused IR back to the emitter Theoretical efficiency is increased to about 40-50% for 0.5-0.6 eV TPV 13 Front spectral control (Filters) Filter Conductive substrate) After H.Sai et al, 2003 14 Converter Materials for Rear Spectral Control Suitable band gap (~0.4-0.6eV) Lattice- matched to existing semiinsulating substrates GaAs or InP Existing converter materials: InGaAs, InGaAsSb/GaSb Problems: Lattice relaxation, degradation InAs 15 Defect filtering in 0.5-0.6 eV InGaAs on InP Cross-Sectional TEM of Full 0.52 eV Structure Misfit dislocation networks confined to InAsyP1-y graded region Low density of threading dislocations (<1x107 cm-2) into active layers Data courtesy of. R.WehrerBechtel/Betis (2004) 16 Rear surface spectral control Low-Bandgap MIM Photovoltaic Devices Data courtesy of Dr. D. Wilt Glenn Research Center at Lewis Field Drawing of monolithic interconnected module (MIM) showing interconnect and two cells Photo of 1cm2 15 cell MIM Reflectance of MIM structure providing spectral control features as well as energy conversion functionality 17 Heat to electric conversion efficiency > 20% Lattice-mismatched 0.6 eV, epitaxially grown InGaAs diodes form the power-producing element. A power conversion efficiency of 20.6&percent; and a power density of 0.90 W/cm2 with a silicon carbide radiator operating at 1058°C is achieved for a 4 cm2 TPV cell operating at 26.7°C. Sergei et al, AIP, 2003 18 Novel Converter Approaches Other Solution: tandems, strained QW new III-V-N materials 19 InGaAs Tandem TPV Devices Inverted (epi-down) Structure Epitaxial surface Metal on epitaxial surface InP Substrate Transparent LCL n/p “High” Eg Cell Isolation Trench Tunnel Junction Buffer Structure 60 mm V=Sumof(Vi) Micrograph processed n/p “Low” Eg Cell Contact / BSR tandem TPV device D. Wilt et al, Proc. TPV 6 conf 2004, ibid M. Wanlass et al 20 Pseudomorphically strained (defect free) MQW TPV cells on InP Conventional p/n Proposed Multi Quantum Well 1.0 InP (100) InGaAs cell 1.00E+021 -2 ) E EgInP E Conventional 0.75 eV InGaAs TPV MQW (A) capture 47% Ga InGaAs cell thermal escape 10% Ga in well - 0.5 EgInP absorption EgQW EFP 1500 K 5.00E+020 EFN recombination Flux (photon/s cm In0.53Ga0.47As Normailized Spectral Response TPV cell In0.53Ga0.47As 1000 K (B) InP (100) 0.00E+000 1.5 2.0 2.5 3.0 Wavelength ( micron) A. Freundlich, US patent Nov 2001 Increased IR sensitivity 21 New IR nanostructured semiconductor lattice matched to InP Absorption threshold (eV) Superlattice of alternate layers of GaAsN and InAs (N), lattice matched to InP. 0.75 Absorption threshold for |3/2,3/2> band to electron bands |3/2,1/2> band to electron bands 0.70 0.65 0.60 0.55 0.50 0.45 0.40 0 T=300K 1 2 3 4 Nitrogen (%) 5 6 A. Freundlich et al, Phys Stat Solidii 2004 L. Bhusal et al, Nanotechnology, 2004 22 Concluding remarks •TPV is still in its infancy •Capable of providing efficient (>20% demonstrated) heat to electricity conversion and high power density •Excellent candidate for waste heat recovery and cogeneration •Enabling technology for space and military applications 23 Absorption threshold 10 10 10 T=300K 0 Transmission probability Transmission probability 0.528eV |3/2,3/2 VB -50 -100 100xGaAs0.95N0.05/InAs SL Thickness of GaAsN/InAs layer=15 /23 Å -0.5 -0.4 -0.3 -0.2 Energy (eV) 10 10 -0.1 0.0 T=300K 0 -50 -100 10 0.00 0.08 0.16 0.24 Energy (eV) 0.32 0.40 L. Bhusal, et.al PRB, 2002, submitted 24 Absorption threshold 0 10 Transmission probability Transmission probability 0.463eV* 1 1100 |3/2,1/2 VB -50 10 -100 10 -0.6 -0.5 T=300K -0.4 -0.3 -0.2 Energy (eV) * ~300meV -0.1 -50 10 100xGaAs0.95N0.05/InAs SL; Thickness of GaAsN/InAs -100 10 0.0 0.00 layer=15/23 Å 0.08 0.16 0.24 Energy (eV) T=300K 0.32 0.40 smaller than the InGaAs lattice matched to InP L. Bhusal, et.al., PRB, 2004, submitted 25