Personal Protective Equipment (PPE) - appropriate use of, SWP

advertisement

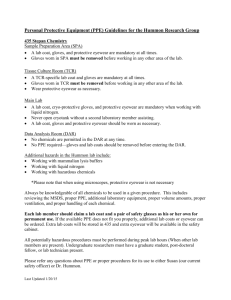

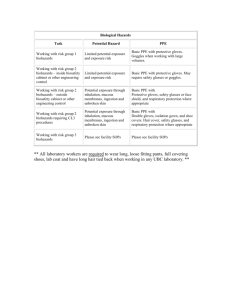

SAFE WORK PROCEDURE Activity/Task: Personal Protective Equipment (PPE) - appropriate use of SWP No: Trim No: Version No: Date Signed Off: Approved: Yes / No RISK IDENTIFICATION AND CONTROLS: Please include all steps involved in the performance of the task NOTE: All PPE required must be listed and the minimum PPE for each chemical must be listed as per the relevant SDS. PROCEDURE STEPS 1. Scope: This SWP outlines the appropriate use of personal protective equipment (PPE), including the sequence of donning and removal, used in the CSU Faculty of Science facilities, Albury-Wodonga Campus. 2. Objectives: To ensure staff and students are suitably protected from possible injury when handling hazardous chemicals or potentially infectious materials. 3. References: Protective Eyewear: AS/NZS 1336 Recommended practices for occupational eye protection Safe Work Procedure Version 1: Sept 2012 Page 1 4. Disposable Gloves: AS/NZS 2161 Occupational protective gloves Footwear: AS/NZS 2210 Occupational protective footwear NSW Health Infection Control Policy Section 2 FSc Personal Protective Equipment Procedure CSU Biosafety Manual Section 5 SWP - Management of Laboratory Gowns in PC1 and PC2 facilities SWP – Personal Protective Equipment Requirements for the FSc Facilities - Footwear Timing: At all times when staff and students are working within the Faculty of Science facilities 5. Responsibilities: Academic and Research Staff: To ensure they have read and understand the requirements set out in this SWP. To determine, in consultation with technical staff, the level of risk associated with practical classes and research and thus the level of PPE required for themselves and their students. To inform their students of the necessity of wearing the appropriate PPE and to enforce the correct wearing of PPE when required. Technical Staff: To ensure they have read and understand the requirements set out in this SWP. To assist academic staff in determining the level of risk associated with specific tasks and thus the level of PPE required. Safe Work Procedure Version 1: Sept 2012 Page 2 To ensure the availability of appropriate PPE. To follow specific Faculty guidelines regarding the laundering of any protective clothing where required Undergraduate Students: 6. To follow instruction from lecturers/demonstrators/tutors/technical staff regarding the wearing and use of PPE In the event of: (emergency or other) Emergency: - Follow facility guidelines for emergency procedures Accidents/Incidents: - Follow facility guidelines for accident/incident management and reporting 7. Location: All Faculty of Science facilities, Albury-Wodonga Campus 8. Training Requirements: Staff and research students should have an appropriate level of knowledge regarding the tasks they are undertaking in order to determine any associated risk and thus the level of PPE required. 9. Plant and Equipment Details: NA 10. PPE Requirements - Appropriate PPE for the task undertaken may be chosen from the following. Protective Eyewear: Low Impact that provide protection from low energy flying fragments and small particles - eg Basic safety glasses Medium Impact that provide protection from medium energy flying particles: - eg Wide vision safety glasses, High Impact that provide protection from high energy flying particles: -eg Face shields, wide vision safety glasses, eye shields and goggles Safe Work Procedure Version 1: Sept 2012 Page 3 Protective Clothing: Cloth gown/laboratory coat that is reusable and will require laundering Disposable gown that is reusable, rear fastening and non-absorbent Disposable Gloves: Single use latex, vinyl or nitrile gloves that may be sterile or non-sterile. In accordance with the policy of minimizing exposure to latex, the majority of gloves available are nitrile. Protective Footwear: Closed in non-permeable footwear is recommended. Joggers/canvas shoes may be acceptable depending on the task and facility being used. Note: See below for the recommended sequence of donning and removing PPE Sequence of Donning PPE: Gown/coat Mask Gloves Protective eyewear Sequence of Removing PPE: Gloves Protective eyewear Gown Mask Wash hands Safe Work Procedure Version 1: Sept 2012 Page 4 11. Engineering Details, Certificates, Work Cover Approvals: NA 12. Maintenance Requirements: NA Safe Work Procedure Version 1: Sept 2012 Page 5 12. Task/Activity Steps: PPE Requirements FSc Laboratories Albury-Wodonga Campus 12.1 Building 666 Teaching Laboratory 2 room 226 – Physiology Laboratory: The tasks carried out in this laboratory include handling of the following: Risk group 1 microorganisms Non-hazardous chemicals Hazardous chemicals at volumes < 50mL Sharp dissecting instruments Potentially infectious materials eg blood and urine (students will only work with their own sample) PPE requirements: Disposable gown - In first session, students are given a gown and resealable bag each. The students hold on to these gowns unless they are contaminated, damaged or begin to smell which are replaced with a new one. In second session, due to the low number of practical classes, students and hazards, students share disposable gowns and these are changed by technical staff every second week. Gowns are disposed of into biohazard bags in the laboratory. low impact safety eyewear – to be cleaned using an alcohol swab/wipe prior to each use disposable gloves – to be disposed of in biohazard bin Closed-in, non-permeable, non-slip footwear. Sports shoes, runners and canvas shoes have been deemed suitable for these spaces Note: Biohazard bins are double bagged and sealed then placed in Sterihealth bins which are collected either fortnightly (first session) or monthly (second session). 12.2 Building 666 Rooms 229 and 234 – PC2 laboratories: The tasks carried out in these laboratories include handling of the following: hazardous materials potentially infectious substances Note: Engineering controls ie fume cupboard and biological safety cabinet, are available to minimize the risks associated with handling these materials. PPE requirements: disposable gown - disposed of into biohazard bags in the laboratory low impact safety eyewear – to be cleaned using an alcohol swab/wipe prior to each use disposable gloves – to be disposed of in biohazard bin Note: Biohazard bins are double bagged and sealed then placed in Sterihealth bins which are collected either fortnightly (first session) or monthly (second session). Safe Work Procedure Version 1: Sept 2012 Page 6 Closed-in, non-permeable, non-slip footwear. Note: Additional PPE is available for specialised hazards e.g. face shield, thermal protective gloves. 12.3 Building 666 Room 224 – Orthotics Manufacturing Laboratory: The tasks carried out in these laboratories include use of/handling of the following: grinders (creating dust and noise) heat guns glue Convection oven. PPE requirements: laboratory coat medium impact safety eyewear hearing protection disposable gloves (when appropriate) P2 respiratory mask (when appropriate) Closed-in, non-permeable footwear Note: disposable gloves/masks may be placed in general waste 12.4 Specialist Teaching Spaces: The tasks carried out in these teaching spaces may include the following: potentially infectious substances use of sharps PPE requirements: disposable gloves ( when appropriate ) closed-in, non-slip, non-permeable footwear when sharps in use Note: disposable gloves may be placed in general waste unless visibly soiled with blood. If soiled they must be placed in biohazard bins. 12.5 Building 666 - Anatomy Wet Labs: The tasks carried out in the wet labs may include the following: observation/preparation of anatomical teaching material handling of hazardous chemicals Safe Work Procedure Version 1: Sept 2012 Page 7 handling of sharps handling of potentially infectious substances PPE requirements: Protective eyewear is provided in the laboratories, must be worn at all times and left in the laboratory after use. As there are no hazardous chemicals handled by students, the wearing of prescription glasses is permitted in place of safety glasses. Staff handling hazardous chemicals outside the fume cabinet must wear protective eyewear. Eyewear must be cleaned using an alcohol wipe prior to each use. Non-absorbent disposable gowns are provided, must be worn at all times and left in the laboratory after use. These are replaced weekly and disposed of in the biological waste. Nitrile disposable gloves are provided, must be worn at all times and disposed of in the biohazard bins. Closed-in non-permeable foot wear is recommended for students. However, as there are no corrosive chemicals being handled by students, closed-in permeable foot wear is permitted. Closed-in, non-permeable and non-slip footwear is required to be worn by all staff. 12.6 Building 666 Rooms 235, 237 and Teaching Laboratory 1, room 239: The tasks carried out in this laboratory include handling of the following: Specimens stored in Ethanol at volumes <500mL Non-hazardous chemicals Hazardous chemicals Sharp dissecting instruments Note: Engineering controls ie fume cupboard are available to minimize the risks associated with handling these materials PPE requirements: disposable gown/non-disposable laboratory coat low impact safety eyewear – to be cleaned using an alcohol swab/wipe prior to each use disposable gloves Closed-in, non-permeable, non-slip footwear. Runners and canvas shoes have been deemed suitable for these spaces Note: Due to the non-infectious nature of the work carried out in these spaces, disposable gowns and gloves are disposed of in general waste. Laboratory coats may be washed in the facilities laundry. 12.7 Building 666 Room 254 Safe Work Procedure Version 1: Sept 2012 Page 8 The tasks carried out in this laboratory include: Processing non-infectious samples Use of the muffle furnace PPE Requirements: Non-disposable laboratory smock that is worn and stored in this room only (not to be worn inside any other facility space) Low impact safety eyewear Disposable gloves/heat proof gloves Closed-in, non-slip footwear. Runners have been deemed suitable for this space Note: Due to the non-infectious nature of the work carried out in this space, laboratory smocks may be washed in the facilities laundry. 12.8 School of Environmental Sciences Offsite Field Trips and Research: The tasks carried out may include the following: Fauna, flora and aquatic surveys Adventure recreation activities. Specialist personal protective equipment required for particular adventure activities to be outlined in the field trip risk assessment e.g personal flotation device, helmets, harness. Visit cultural sites PPE requirements: Sturdy, closed-in footwear Wide brimmed hat Long sleeved shirt and pants wet and or cold weather apparel (where required) – i.e. rain/snow jacket, water proof pants etc sunscreen Safe Work Procedure Version 1: Sept 2012 Page 9 Safe Work Procedure Version 1: Sept 2012 Page 10 SAFE WORK PROCEDURE: Assessment dates Initial assessment date: Current assessment date:29/8/2013 Reassessment due date: Assessors: Name: Signature: Date: Amanda Eddy 29/8/2013 Caroline de Koning 5/09/2013 Recommendation: (Technical Officer/Supervisor/Manager) Follow up required: Yes / No Name: Date: Signature: Cherryl Kolbe 5/09/2013 Approval: (Facility Manager, Head of School, Manager University Laboratories) Name: Safe Work Procedure Version 1: Sept 2012 Signature: Date: Page 11 Risk Assessment Matrix: Evaluate the level of risk associated with the hazard identified. SEVERITY LIKELIHOOD How severely could it hurt someone How likely is it to be that bad? or How ill could it make someone? !!!! Kill or cause permanent disability or ill health ++ + - -- Very likely Could happen at any time Likely Could happen sometime Unlikely Could happen, but very rarely Very unlikely Could happen, but probably never will 1 1 2 3 !!! Long term illness or serious injury 1 2 3 4 !! Medical attention and several days off work 2 3 4 5 ! First aid needed 3 4 5 6 Safe Work Procedure Version 1: Sept 2012 Page 12 Safe Work Procedure Version 1: Sept 2012 Page 13 I have read and understand this Safe Work Procedure: Name: Safe Work Procedure Version 1: Sept 2012 Position/Role: Signature: Date: Page 14