Boundary Layer Measurements Nomenclature

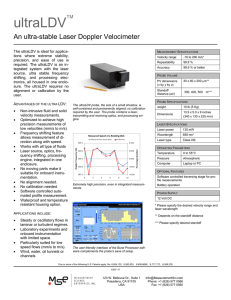

advertisement

Boundary Layer Measurements Prepared by Professor J. M. Cimbala, Penn State University Latest revision: 11 January 2012 Nomenclature Symbols d df f F n Rex u distance between laser beams, just prior to the focusing lens (d = 38.0 mm for our fiber optic probe) fringe spacing in the focal volume of the LV focal length of the LV focusing lens (f = 160.2 mm for the Dantec fiber optic probe) Doppler frequency length of the flat plate (from leading edge to the furthest possible measurement location, which is around 15 inches) index of refraction (n = 1.332 for air to water) Reynolds number based on length x: Rex = Vx/ (other Reynolds numbers defined similarly) streamwise component of velocity at some location inside the boundary layer (in x-direction) u* friction velocity (for turbulent boundary layer), u* w U x y z magnitude of mean freestream velocity (outside of the boundary layer) coordinate in the plane of the flat plate (in flow direction) coordinate normal to the flat plate (in direction through the boundary layer) coordinate in the plane of the flat plate (in direction normal to the flow direction) boundary layer thickness; by convention, is defined as the 99% thickness wavelength of laser light beam ( = 632.8 nm for a helium-neon laser) coefficient of viscosity ( = 1.00 10-3 (Ns)/m2 for water at 20oC) coefficient of kinematic viscosity (for water, = 1.00 10-6 m2/s at room temperature) dual laser beam half angle (for our lens, = 6.764o) density of the fluid (for water, = 998 kg/m3 at room temperature) L Educational Objectives 1. 2. 3. Develop familiarity with operation of a small closed-loop water channel. Become acquainted with the basic concepts and operation of Laser Velocimetry (LV). Measure both laminar and turbulent boundary layer profiles on a flat plate, and compare. Equipment 1. 2. 3. 4. 5. 6. closed-loop water channel, built by Engineering Laboratory Design, Inc. Toshiba frequency controller (to control the pump speed, and hence the freestream velocity in the water channel) Dantec FlowLite fiber optic laser velocimeter (LV) system, with BSA software and manual traversing system personal computer flat plate boundary layer apparatus, inserted into the water channel from the top model submarine apparatus, also inserted into the water channel from the top Background A. Laser Velocimetry The flow measurement technique used in this experiment goes by several names in the literature: laser Doppler anemometry (LDA), laser Doppler velocimetry (LDV), or simply laser velocimetry (LV). The technique utilizes a laser to measure velocity at a point in a flow field. The greatest advantage of laser velocimetry is that it is non-intrusive, unlike measurements with a hot-wire or Pitot-static probe, which can sometimes (by their physical presence) alter the very flow they are trying to measure. Other advantages are: there is no temperature or density dependency, and no calibration is required. The disadvantages include high cost, the necessity of unobstructed optical access to the measurement point, difficulties in alignment, and oftentimes the need to seed the flow with small particles. This later point is critical, for it is by the motion of particles passing through the laser beam that laser velocimetry works. In a typical LV setup, a laser beam is split (by a beam splitter and mirror) into two parallel beams of equal intensity. The beams are then focused (by a lens) to a point in the flow, as sketched in Figure 1. Cable Receiving optics To electronic processor Scattered light Mirror Focal volume d He-Ne laser u Flow Beam splitter f Focusing lens Figure 1. Schematic diagram of a single-component LV system. The focal volume is the region in space where the two beams intersect. Due to the wave-like nature of light, an interference fringe pattern (bright-dark-bright-dark light intensity) forms in this region, as sketched in Figure 2, which is a close-up of the focal volume. Focal volume with fringe pattern df u Fluid particles that pass through the focal volume Figure 2. Close-up view of the focal volume of an LV system. The fringe pattern in the focal volume is formed by the intersection of two identical laser beams. From trigonometry, the fringe spacing df (the distance from a bright region to its closest neighboring bright region) is given (typically in nanometers, nm) by df 2 sin (1) where is the wavelength of the laser light (for our helium-neon laser, =632.8 nm), and is the half-angle between the two beams. If a small particle in the flow passes through the focal volume (Fig. 2), it passes through this fringe pattern of alternating bright-dark-bright-dark light intensity. The faster the particle travels, the faster it passes through the bright-darkbright-dark fringe pattern. The receiving optics and electronics enable us to measure the frequency of the light scattered from the particle. If F represents the frequency of the bright-dark-bright-dark scattered light (also called the Doppler frequency, and typically given in MHz), the particle velocity is simply u = df F (2) Since df is a constant independent of fluid temperature, density, etc., we have in Eq. (2) a linear relationship between velocity u and measured Doppler frequency F. If there are sufficiently many particles in the flow, and the particles are small enough to be carried along with the flow without disturbing the flow, we have a non-intrusive technique for measuring flow velocity. In air flows, the air must be seeded with tiny dust or smoke particles or with micro-drops of water in order to provide enough particles for a good LV signal. In water flows, however, ordinary city tap water contains enough particulate matter so that seeding is usually unnecessary. Alignment of the laser optics has traditionally been the most frustrating aspect of obtaining quality LV signals. However, with the advent of fiber optics in the 1980’s, alignment problems have been eliminated. In a fiber optic LV system, the laser, beam splitter, mirror, and part of the receiving optics are permanently aligned inside the electronics box. A portable probe head contains the focusing lens and the rest of the receiving optics. Fiber optic cables carry both the transmitting and receiving optical signals from the probe head to the electronics. Thus, only the LV probe head itself needs to be traversed. Since the fiber optic cables are flexible, the LV probe head is simply mounted on a two-axis traverse, where it can be translated or even rotated without affecting alignment of the laser beams. B. Boundary Layer on a Flat Plate Chapter 7 of Reference 1 gives a brief introduction to boundary layers. As one approaches a wall from a freestream flow, the velocity decreases from U to zero very rapidly in a thin viscous layer called a boundary layer. (The velocity right at the wall must be zero, of course, to satisfy the no-slip condition.) Boundary layers can either be laminar or turbulent, depending on the Reynolds number. For a boundary layer along a flat plate, Reynolds number is based on the freestream velocity U , and the distance x from the leading edge of the plate, i.e. Rex = Ux/ or Ux/. Boundary layer thickness is defined as the location where the velocity in the boundary layer reaches 99% of the freestream velocity. increases with downstream distance x. Equations for boundary layer thickness as a function of x are well established for both laminar and turbulent boundary layers on a smooth flat plate, as given in Reference 1: Laminar flat plate boundary layer: Turbulent flat plate boundary layer: x x 5. 0 Re x1 2 (3) 0.16 Re x1 7 (4) On a smooth flat plate with a very clean freestream, transition from a laminar to a turbulent boundary layer occurs between Reynolds numbers of about 1 105 and 3 106. In cases where a turbulent boundary layer is desired, but the Reynolds number is not quite high enough to achieve a naturally turbulent boundary layer, roughness or other disturbances on the plate (trip wires, vortex generators, etc.) can be used to cause early transition to turbulence. In this lab, you will use the laser velocimeter to measure both laminar and turbulent boundary layer velocity profiles on a flat plate. There is an optical affect which is important to understand when the LV system is used in water (as in this lab). As the laser beam travels from air into water, there is refraction of the beam, along with a corresponding change in its wavelength. For air to water, the index of refraction n is 1.332. Although both beam angle and wavelength change as the beam passes from air into water, it turns out that the fringe spacing df (from Eq. 1) is not affected. Moreover, the frequency of the laser light is not affected by refraction; Eq. (2) is therefore still valid for determining the flow velocity. However, if the LV probe head (which is located in the air outside the water channel) is moved to the right in Figure 1, normal to the water channel side wall, the distance actually traveled by the focal volume in water is equal to 1.332 times the distance traversed by the probe head in air. One must be careful to correct for this optical effect. For example, if one moves the fiber optic LV probe a distance of 1.00 mm (in the air outside of the water channel) further towards the water channel, the focal volume inside the water channel will actually move 1.332 mm. Fortunately, in this lab experiment, the probe is traversed only in directions parallel to the water channel side wall. Thus, this correction factor is not required. Please make a mental note of it, however, if you ever perform more complex LV measurements in water. References 1. Çengel, Y. A. and Cimbala, J. M., Fluid Mechanics – Fundamentals and Applications, McGraw-Hill, NY, 2006. 2. White, F. M., Fluid Mechanics, Ed. 5, McGraw-Hill, NY, 2003. 3. Dantec’s instruction manuals for LV system and software.