TMPS27

advertisement

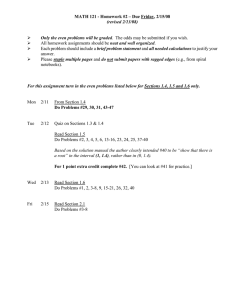

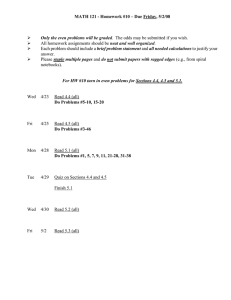

Production Systems TMPS27 Mats Björkman Manufacturing Engineering /(Industriell produktion) mats.bjorkman@liu.se 013- 28 11 36, 0709 – 52 11 36 Overview of the course planning • The aim is to increase the understanding of production. Not just transferring information and explicit knowledge. • Link technology – organisation – personell – ”philosophy” – etc • Train the students to identify, analyze and synthetize the different aspects of a production assignment/task • This requires that the students participate actively during the lectures and seminars 2 Goal After the course the student should: • Have insight how manufacturing equipment, handling equipment and control technology are utilized for the design and operation of flexible manufacturing systems. Also, taking into account the interaction between man and machine. • Be able to use concepts and models for analysis of production systems with consideration to product development and production strategy. • Be able to “design” production systems for various industrial needs. • In the context of a “small” project engineering team discuss and argue for the selected solutions for production. 3 Course content For example: • The main types of production systems in the form of multi-purpose workshops, product workshops and general production workshops • Automated lines, functional design, NC shops and FMS • New production system concepts in the form of mass-customization, individualized production, functional FMS • Methods to achieve flexibility • The "Japanese production philosophies" applied to the machines in the production system. • Methods, equipment, and systems for production of products/components in the “new coming” materials: Composite/carbon fibre 4 The project assignment: • By working in a project the students will be trained to identify and analyze problems based on given conditions in an actual industrial context. • The project groups will be working with different types of problems/tasks. • These will be discussed during seminars that will provide a wider and deeper understanding of the whole • The project team will present the project results in a concise, adequately and clearly orally and in a report. • The intention is that project teams will consist of students with different background, coming from different master programs, etc. • One goal of the course is to train the students to work in multidisciplinary teams. Ideally also in multi-nationality teams • The intention is that you should also utilize knowledge from previous courses in the project work. 5 Week Day 13 14 16 17 18 19 20 Date Time Room Mon 150323 8-10 A37 Tue 150324 13-17 Wed 150325 10-12 S41 Production Systems Development Mats Björkman P44 Flexibility as a concept Mats Björkman Fri 150327 8-10 Tue 150331 13-17 Wen 150401 10-12 A33 Lean Production, theory and experiences from industry Jelena Kurilova Mon, 150413 8-10 A33 Chapter 2: Manufacturing Operations Mats Björkman Study visit Chapter 2 Manufacturing Operations and 13 Manufacturing System Design Mats Björkman, etc Study visit Tue 150414 13-17 Wed 150415 10-12 A33 Fri 150417 8-10 A33 Mon 150420 8-10 A33 Tue 150421 13-17 P44 Wen 150422 10-12 A33 Mon 150427 8-10 A33 Tue 150428 13-15 A34 Wen 150429 10-12 A33 Tue 150505 13-17 A36 Wed 150506 Study visit 10-12 A33 Fri 150508 8-10 A33 Tue 150512 13-15 P44 Wed 150513 10-12 A33 Study visit Composite Manufacturing, part 1: Introduction to composites Composite Manufacturing, part 2: Manufacturing processes and systems Initial Project Seminar. Presentation of the RPA and short description of the impressions from the study visits. Short presentation of the specific companies’ problems. Chapter 13 Manufacturing Systems Design and 14 SingleStation Manufacturing Cells Chapter 14 Single-Station Manufacturing Cells and 15 Manual Assembly Line Defined Chapter 16 Automated Production Lines and 17 Automated Assembly - Defined Model Based Definition as a tool for efficient manufacturing - Saab Aeronautics Mid-term Project Seminar, Description and discussion concerning each individual project Application of multi agents in production Mats Björkman Andreas Björnsson Andreas Björnsson Mats Björkman Mats Björkman Mats Björkman Mats Björkman Anna Malm Mats Björkman Luis Ribeiro Combining flexibility and efficiency in assembly Chapter 18 Cellular Manufacturing Composite Manufacturing, Saab Mass Customization, Chapter 19 Flexible Manufacturing Systems Björn Diffner Mats Björkman Jan Erik Lindbäck Mats Björkman 21 Fri 150522 8-10 A33 22 Mon, 150525 8-10 A33 Backup time, used if needed Mats Björkman 13-17 R43 Project Seminar, Final presentation of projects Mats Björkman Tue 150526 6 Study visit Subject Lecturer General introduction to the course, course objectives and structure, who are the lecturers. Project presentation. The Rapid Plant Assessment method. Chapter 1 of Automation Mats Björkman Production Systems and Computer-Integrated Manufacturing. Introduction Mats Björkman, etc Study visits