Magnetic Levitation Experiment worksheet (.doc version)

advertisement

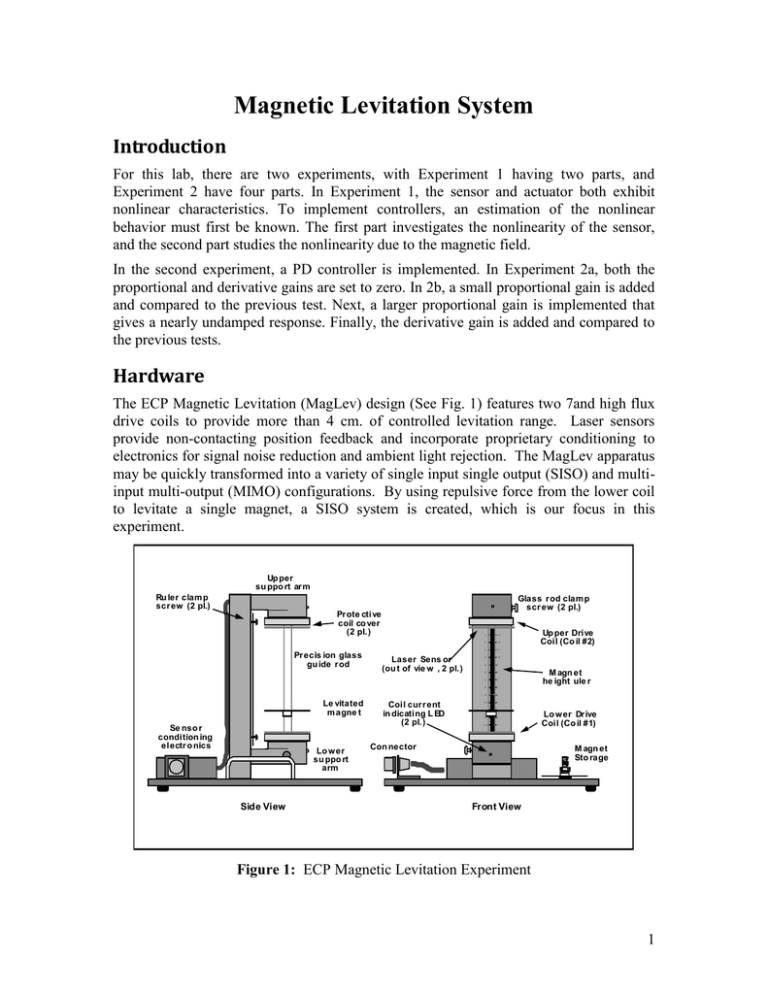

Magnetic Levitation System Introduction For this lab, there are two experiments, with Experiment 1 having two parts, and Experiment 2 have four parts. In Experiment 1, the sensor and actuator both exhibit nonlinear characteristics. To implement controllers, an estimation of the nonlinear behavior must first be known. The first part investigates the nonlinearity of the sensor, and the second part studies the nonlinearity due to the magnetic field. In the second experiment, a PD controller is implemented. In Experiment 2a, both the proportional and derivative gains are set to zero. In 2b, a small proportional gain is added and compared to the previous test. Next, a larger proportional gain is implemented that gives a nearly undamped response. Finally, the derivative gain is added and compared to the previous tests. Hardware The ECP Magnetic Levitation (MagLev) design (See Fig. 1) features two 7and high flux drive coils to provide more than 4 cm. of controlled levitation range. Laser sensors provide non-contacting position feedback and incorporate proprietary conditioning to electronics for signal noise reduction and ambient light rejection. The MagLev apparatus may be quickly transformed into a variety of single input single output (SISO) and multiinput multi-output (MIMO) configurations. By using repulsive force from the lower coil to levitate a single magnet, a SISO system is created, which is our focus in this experiment. Up per su ppo rt ar m Ru ler clam p scr ew (2 pl.) Glass r od clam p scr ew (2 pl.) Pr ote ctive coil co ver (2 pl.) Pr ecis ion glass gu ide r od Le vitated m agne t Se nso r condition ing electr o nics Lo wer su ppo rt arm Side View Laser Sens or (ou t of vie w , 2 pl.) Coil cur r ent in dicating L ED (2 pl.) 0 1 4 1 1 3 2 1 2 3 1 1 4 1 0 5 9 6 8 7 7 8 6 9 5 1 0 4 1 1 3 1 2 2 1 3 1 1 4 0 Con nector Up per Drive Coil (Co il #2) M agn et he ight ule r Lo wer Dr ive Coil (Co il #1) M agn et Sto rage Front View Figure 1: ECP Magnetic Levitation Experiment 1 Safety Read the safety information found in Appendix B on the course webpage Specific to this experiment: select Abort Control immediately after measuring magnet height to minimize heat buildup in the coil and servo amplifiers. Hardware/Software Equipment Check Prior to starting the lab, complete the following steps to ensure that the equipment is working. Step 1: With power switched off to the Control Box, enter the ECP program by double clicking on its icon. Turn on power to the control box. The laser sensors should illuminate the magnet in a thin red line on both the upper and lower magnet surfaces. Step 2: Gently raise the magnet by hand (touch the edges only with clean hands and do not obstruct the laser beam). Observe a change in the Sensors counts. The Control Loop Status should indicate "OPEN" and the Drive 1 Status, Drive 2 Status, and Servo Time Limit should all indicate "OK". 2 Experiment 1: System Identification Note: Calibration measurements should be taken off the top surface for sensor 1 and from the bottom surface for sensor 2. This may require that the ruler (on the test rig) be adjusted such that the height at the zero position is measured as zero on the ruler. Experiment 1a: Sensor Characteristic In the first part of the experiment, a polynomial fit of position versus the sensor needs to be created. In later parts of the lab, this relationship will be used to find the position accurately by observing the sensor counts and transforming it via your polynomial. Procedure 1. Read through Experiment 1 thoroughly before starting. Setup the mechanism with one magnet only resting on the lower drive coil. Make certain to have clean hands when touching the magnet - avoid touching the white surface if possible. Power to the Control Box should be off. Construct tables similar to of Table 1-1 and Table 1-2, found below to record data. 2. Set up the ECP software sensors. Select Abort Control to make sure that no real-time controller is active. Turn on power to the Control Box. Observe the laser light beam on the upper and lower magnet surfaces. Move the magnet manually up and down to verify that the sensor counts displayed on the Background Screen are changing. 3. Adjust the ruler. Sight along the top of the magnet and adjust the ruler height so that the 0 cm. position precisely matches the plane of the top of the magnet. 4. Record the raw sensor output at the 0 cm. position as read from the Sensor 1 display on the Background Screen. Refer to the notes below regarding moving the magnet to the desired calibration positions and reading the sensor counts. Manually move the magnet to the 0.50 cm position and read and record the raw sensor output. Continue moving and recording the sensor data according for the magnet positions in Table 1-1. 5. Notes on taking sensor calibration data: 1) Hold the magnet only by the edges and do not block the laser light. 2) Apply light finger pressure radially inward so that the magnet bushing is snug against one side of the glass rod. This will assure that the magnet is not cocked relative to the rod and is approximately horizontal. It should also assure that the magnet does not move during the measurement. Any movement can lead to inaccurate results. Further enhancement in the accuracy of results of this and the next section may be obtained by taping a 3 ruler (cm./mm. graduations) alongside of the upper and lower sensor/coil support arms with the ruled edge very close to the magnet travel zone. In this way the magnet height may be more reliably read. 3) When the magnet is at the close end of travel relative to the sensor (at the bottom for sensor #1, at the top for sensor #2) rotate it and find the clocking position where the sensor output is approximately the average of the highest and lowest values. There may be as much as ±1000 counts difference between the highest and lowest values (if there is more than this, clean the white surface). This amounts to an equivalent position measurement error of less than 1 mm and becomes much less for positions further away from the coil. Try to maintain this approximate clocking for the remainder of the magnet positions when taking sensor data in Step 4 (e.g. keep the magnet polarity “N” label pointed in the same direction). There will be some noise in the sensor reading; so “visually average” the values displayed. The student need only read the sensor to three significant digits for the purposes here. Use the following table for calibration data: Table 1-1 Sensor Calibration/Linearization Data Magnet Position for Sensor #1 (cm) Y1 raw (Sensor 1, Counts) 0.00 0.50 1.00 2.00 3.00 4.00 5.00 6.00 Plot the data points of sensor counts vs. magnet position in MATLAB. From the plot, determine a reasonably simple polynomial function y = f(x) that accurately fit the data points. Add this polynomial to your plot. (A first or second order polynomial will be sufficient) The lab report must include a plot of sensor counts vs. magnet position with the polynomial fit shown over the data. Also include the fitted polynomial equation including the coefficients found from MATLAB. The final report is expected to include: 4 Using Figure 1 above, label the following: Sensor Actuator Describe the following in terms of the physical meaning of each: Actuator Output System Output Reference Input One (1) MATLAB Plot along with titles, labels and the fitted polynomial equation printed on the plot - Plot of Magnet position (x axis) and Sensor 1 (y axis) One (1) Excel table of the original data - Table 1-1 of Magnet Position and Sensor 1 data For all the questions highlighted, the questions should be copied and pasted into the student’s lab report and explicitly answered immediately thereafter. Experiment 1b: Actuator Characteristic Similar to 1a, the actuator (in this case, the electromagnet) also exhibits non-linear behavior. A polynomial fit of the control effort compared to position needs to be created. The mechanism should be in the same configuration as in the last section. Assure that the north pole of the magnet is facing upward. The ruler should again be adjusted to measure off the upper surface of the magnet when it is resting in its lowermost position. Follow the procedure in Experiment 1b below to gather the data needed to complete the table, also shown below. Use a simple user-defined control algorithm of the type: begin control_effort1 = 5000 end Procedure 1. Input the code. Write a simple real-time algorithm to activate actuator coil #1 (i.e. put control effort values on the DAC) with a constant control effort of 5000 counts.1 Review the algorithm with the instructor or laboratory supervisor before proceeding to the next step. 1 These counts are converted to a voltage via a digital-to-analog converter (DAC), then to a current via the servo amplifier, to a magnetic field via the coil, and finally to a force by repulsion of the magnet’s magnetic field. The scaling of all of these transformations affects the system gain and will be examined in 5 2. Enter Setup Control Algorithm via the Setup menu. Select Edit Algorithm. This opens up the control algorithm editor. Type required codes in the editor window. Then click File on the menu bar and choose Save changes and quit. A dialogue window will pop up, asking you to enter file name to save these codes. Once you name the file, click Save and the file will be stored on the designated directory. In addition, both the dialogue window and editor window will disappear and you will return to the Setup Control Algorithm window. Then click Implement Algorithm, codes you just entered will be implemented. If you wish to use other codes stored on computer, you can choose Load from disk… to select the program file you want load. If the above steps do not work, please refer to Reference in the end of this manual. 3. Record the height of the magnet corresponding to 5000 counts in a table similar to Table 1-2. Spin the magnet (again touching only its edge) to reduce the effects of friction so that the true equilibrium height is observed. 4. Follow the step 2j) to reduce the control effort to 4000 counts and implement. Notice the magnet height becomes lower. Record the magnet height. 5. Repeat step 4 to find the control effort value at which the magnet is lifted only a very slight amount above the support pads (i.e. the 0+ position). Again, spin the magnet to reduce the effects of friction. 6. Repeat step 4 for the remaining control effort values of Table 1-2. Select Abort Control immediately after measuring magnet height to minimize heat build-up in the coil and servo amplifiers during exposure to the higher control effort values (those greater than 10,000 counts) Do not exceed 22,000 counts of control effort. Table 1-2. Actuator Calibration / Linearization Data more detail in the sections that follow. See also Chapter 4 for a description of the control hardware and software functionality. 6 Magnet Position (cm) u1raw (Uncompensated Control Effort, counts) 0.00 4000 5000 6000 8000 10000 12000 14000 18000 22000 The final report is expected to include: One (1) MATLAB Plot along with titles, labels and the polynomial fit on the plot - Plot of Magnet position (y axis) and Control Effort (x axis) One (1) Excel table of the original data - Table 1-2, Magnet Position and Control Effort Briefly describe the trend of the nonlinear behavior of the magnet position as the control effort increases. In the text of the report, briefly describe possible reasons why the system is nonlinear (what are the physical dynamics causing the nonlinearity?) For all the questions highlighted, the questions should be copied and pasted into the student’s lab report and explicitly answered immediately thereafter. Experiment 2: PD Control of the system to an equilibrium point This section will explore the control of a nonlinear system using a simple linear proportional and derivative (PD) controller: C(s) = kp+kds where kp is the proportional control gain and kd the derivative control gain. The student will use and modify the control program given below to conduct the experiment. Again, the boxed code shown earlier is a starting point that can be loaded in and modify according to various steps of the experiment. 7 Note that the student needs to determine a value for the variable, y1rawo, in the program. ;******************DECLARE VARIABLES******************* #define y1cal q2 #define y1rawo q3 #define kp q4 #define kd q5 #define kdd q6 #define Ts q7 #define y1str q8 #define pos_last q15 #define u1str q16 #define u1o q17 #define u1 q18 ;************************INITIALIZE*********************** Ts = 0.000884 ;must also set Ts in dialog box. control_effort1 = 0 control_effort2 = 0 ;Specify Parameters u1o = 5000 ;gravity feedforward (u_bar in linearization analysis) y1rawo = ##### ;sensor#1 value at static equilibrium corresponding to u10 value above (y_bar in linearization analysis). You need to fill this in before implementing control. ;Figure out a value of the sensor counts above using ;the magnet position in Table 6.1-2 along with y = f(x) obtained from Table 6.1-1 data. kp = 0 ;proportional control gain kd = 0 ;derivative control gain kdd = kd/Ts ;*************BEGIN REAL-TIME ALGORITHM************** begin y1str = y1rawo- sensor1_pos ;position error u1str = -kp*(y1str) -kdd*(y1str-pos_last) ;CONTROL LAW pos_last = y1str u1 = u1str + u1o ;add gravity offset control_effort1 = u1 q10 = -y1str ;reverse polarity for plotting q11 = -cmd_pos ;reverse polarity for plotting end Experiment 2a: kp = kd = 0 In this first experiment, there are no gains used to control the system and thus the control effort is set to zero. 8 Procedure: 1. Set kp and kd to zero and control effort u1o to 5,000 in the program. Run the program to observe the disk to reach its equilibrium position. Press the disk down to the bottom (or raise it up) and then let go a couple of time to feel and observe how the system responds. Fill the observed equilibrium position in at the spot provided in the algorithm code above. 2. Rotate the magnetic disk slightly to free it up from possible static friction that may prevent it from reaching its equilibrium. Then take the following readings from the PC and include it in the report: a. Use the data acquisition of the PC system to record and plot two seconds of the motion of the disk with the disk pressed down against the bottom plate to begin with: b. To set the data acquisition, go to Data and then Setup Data Acquisition. Select Sensor 1 Position. Click okay. Then, go to Command, Trajectory 1. Select Step, and input a step of 0 counts, dwell time of 2000 ms, and 1 rep. Click Okay twice. c. Use MATLAB to create the plots and to accurately determine the settling time and frequency response. Hint; use the Data cursor tool in the plot window in MATLAB The final report is expected to include: One (1) MATLAB Plot along with titles and labels. Be sure to include Data Cursor points if determining the frequency. - Plot of the disk response Calculations or clearly indicate for the following quantities. Be sure to include units for ALL values: - Disk equilibrium position from the top of the plate - Disk equilibrium Sensor 1 Counts - Disk equilibrium Control effort 1 voltage - Time to settle into equilibrium - Frequency of the response Experiment 2b: Undamped free vibration (limit cycle) For 2b, the gain is increased to create a nearly undamped system. Procedure: By trial and error with the program, determine the maximum value of kp to make the system vibrates up and down like an undamped free vibration when the disk is pressed down (or lifted up) and let go. You should observe that, for any perturbation, the system will vibrate up and down at the same amplitude indefinitely. A system that exhibits this type of behavior is said to be displaying a limit cycle. A larger kp than this would make the system unstable, which causes the disk rapidly striking the bottom plate (light hits are 9 OK). In this setting, since there in inevitably a damping coefficient from the friction between the disk and the glass tube a perfectly undamped system is unachievable. The students should instead look for a kp value that causes the disk to steadily oscillate for at least 8 seconds. Try kp starting from 0.5. Do NOT let the disk hit the bottom hard. Use the data acquisition of the PC system to record two seconds of the free vibration with the disk pressed down against the bottom plate to begin with. k p k sy s 1+k 1' n = m = k dk sy s 1 2m n Where ksys1 = 100 N/m, k1’= 0.053, and m = 120 g as given by ECP. Use MATLAB to create the plots and to accurately determine the frequency of the response. Hint, use the Data cursor tool in the plot window in MATLAB. In the lab report, you will need to derive the equations above for the natural frequency and damping ratio above. To start, you have a nonlinear system represented by the following: Fw Figure . Block Diagram of SISO System Showing Nonlinear Elements The force out of the actuator is nonlinear, hence the dotted line showing that y enters the equation, but does not multiply through the equation. The force equation for the magnetic field nonlinearity is given by: u1 test Fw = a y 1 +b 4 By linearizing the above equation in terms of perturbations in u and y, show that the above diagram simplifies to the diagram below. You need to show the linearization 10 process from an FBD of the puck all the way to the final, linear differential equation. Here you are supposed to use a and b to express ksys1 and k׳1. Figure. Reduction of System to Linearized Form In the case of a PD control law, assume that the system becomes: u*1 (s) r(s) kp ksys – – PD Controlle r 1 ms2 + k'1 y*1 raw(s) Li neari ze d Pla nt kds a) Low er Sensor/Actuator Locationsimplifies to: Using block diagram algebra, show that the above * y 1 raw(s) k p k s ys1 /m y*2 raw(s) r(s) u*2(s) = 1 ' r(s) kp sys s + k k s2 + k k k/m 2+k /m – – d s ys1 PD p s ms ys1 - k1'2 Li neari ze d Controlle And from this, show that rthe damping ratio equations Pla ntand natural frequency equations ׳ above are correct. Here you kds are supposed to use kp, ksys1, kd and k 1 to express ωn and ζ. Calculate the frequency ofb)the response based on the equation above and using your plot Uppe r Sensor/Actuator Loca tion from Matlab. Compare the two results. The final report is expected to include: One (1) MATLAB Plot along with titles and labels. Be sure to include Data Cursor points if determining the frequency. - Plot of the “undamped” response Calculations or clearly indicate for the following quantities. Be sure to include units for ALL values: - Experimental value of kp used - Experimental value of the frequency - Calculated value of the frequency 11 Experiment 2c: Creating an unstable system In this experiment we will experimentally determine a kp that induces an unstable response. Remember: a system that, for any small perturbation, gains amplitude with each subsequent oscillation is exhibiting unstable behavior. Procedure: By trial and error with the program, determine the minimum value of kp to make the system vibrate out of control for any small perturbation. Set up your data acquisition so that you are using a step response with a step size of 0 counts, dwell of 2000 milliseconds and 1 rep. For each value of kp start by pressing execute under command; make sure normal data sampling is selected and only execute trajectory one. Move the disk approximately 500 counts from its equilibrium position press run and then release the disk and observe its response. Use the data acquisition of the PC system to record two seconds of the free vibration with the disk pressed down against the bottom plate to begin with. Use MATLAB to create the plot. Determine the frequency of the system for the first half of data sampling and compare it to the frequency of the latter half. Knowing that this system is unstable in conjunction with your knowledge of the s-plane, where would you say the eigenvalues of this system fall on the s-plane? The final report is expected to include: One (1) MATLAB Plot along with titles and labels. Be sure to include Data Cursor points if determining the frequency. - Plot of the “unstable” response Calculations or clearly indicate for the following quantities. Be sure to include units for ALL values: - Experimental value of kp used - Experimental value of the frequency of the first half of response - Experimental value of the frequency of the second half of response Experiment 2d Adding damping to the system The last test now includes damping, which can create a system that has a very quick settling time, compared to the near infinite settling time of 2c. Procedure: 12 Finally, explore how the addition of the derivative control component may stabilize and damp out the free vibration observed in the last step of proportional control alone. Try a small positive value for kd such as 0.0001 to begin with and observe its effect on the free vibration when the students press down or raise up the disk. Then increase the kd value to a point where the free vibration will damp out most quickly and reach the equilibrium fairly fast. If too large a kd value is used, it would cause the control effort to go over the limit. Experiment this and determine the best kd value for the stabilization. Your goal should be to have the fastest possible settling time. Use data acquisition to record the damped response with the disk pressed down against the bottom plate to begin with. Determine the damping gain necessary to achieve an “optimal damping ratio” of 0.707. Compare the response associated with this Kd value to the response obtained from your “guess” above. Extra Credit: 0.707 is not the damping ratio that gives the fastest settling time, even though it is often considered “optimal damping.” Calculate the damping ratio that achieves a 5% maximum overshoot, and implement the resulting Kd value. If you show this calculation and get a correct answer, you will receive 5 extra credit points. Use MATLAB to create the plots and to accurately determine the settling time and frequency response. Hint; use the Data cursor tool in the plot window in MATLAB Note the difference of the settling time from that in Experiment 2a: Does it take more or less time to settle. Why? Explain the difference of the frequency from that in Experiment 2c. Is it higher, lower or no change? Why? The final report is expected to include: Two (2) MATLAB Plot along with titles and labels. Be sure to include Data Cursor points if determining the frequency. - Plot of the damped response by guessing - Plot of the damped response by calculations Calculations or clearly indicate for the following quantities. Be sure to include units for ALL values: - Guessed value of kd - If measurable, the frequency from the plots - Settling time for both plots For all the questions highlighted, the questions should be copied and pasted into the student’s lab report and explicitly answered immediately thereafter. 13 Reference: Procedure to implement control algorithm if algorithm editor does not work. a) Enter Setup Control Algorithm via the Setup menu. Select Edit Algorithm. This opens up the control algorithm editor. b) Click ‘File’ on the menu bar and select ‘New’ under ‘File’. c) If a dialog box opens up, click ‘Sure’; otherwise, go to the next step. d) Go to menu bar and click ‘File’ again. This time, click ‘Save As’ and save this file in your personal folder that you have. e) Go to your personal folder and find your control algorithm file. The file should has the suffix -- .alg. Double click it to open this file. f) If a dialog box saying ‘Windows can’t open this file’ opens up, then choose ‘Select a program from a list of installed programs’ and click ‘OK’. Then choose Notepad to open this file. g) Input your control algorithm and save it. h) Go back to ECP software. In the Control Algorithm Window, click ‘Load from disk…’ and choose the file you just edited and click OK. i) You will see the Control Algorithm window showing that your file has been successfully loaded. Then your algorithm is ready to use. If you click Implement, then this algorithm will be executed on your apparatus. j) If you want to edit your control algorithm, click ‘Cancel’ to exit from Control Algorithm window. You have to make sure that behind ‘User Code:’, ECP shows ‘(no file selected)’ because ECP sometimes does not overwrite the previously loaded programs when a new program is loaded. In that case, exit ECP and launch it again. Find the .alg file and edit it. Save it and load it in ECP. Then ECP has a new control algorithm to use. 14