Galvanometer

advertisement

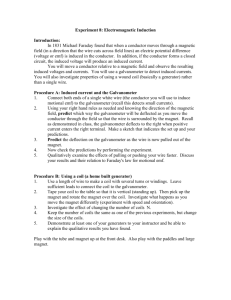

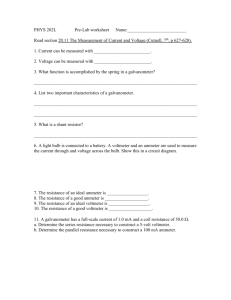

Galvanometer The galvanometer, a device used to measure extremely small electrical currents, traces its origin back to 1820. In that year Hans Christian Oersted (1777-1851) discovered that an electric current flowing in a wire created a magnetic field around it, deflecting a magnetized needle. This effect became the basic principle behind the galvanometer. In the same year André Ampère (1775-1836) used the effect to invent a device to measure electric current. He suggested it be called the galvanometer, in honor of Luigi Galvani (1737-1798), a pioneer in the investigation of electricity. The first practical use of the galvanometer was made by Karl Friedrich Gauss in 1832. Gauss built a telegraph that sent signals by deflecting a magnetic needle. This style is known as a moving-magnet galvanometer. More commonly used today is the moving-coil or moving-mirror galvanometer, sometimes called a D'Arsonval galvanometer. The invention of the moving-coil galvanometer is credited to Johann Schweigger in 1825, three years later Italian physicist C. L. Nobilli designed an astatic type. It consists of a coil that has been wound with very fine wire mounted between the poles of a permanent magnet. Attached to the coil is a pointer. When electric current is turned on, the coil turns and the deflection angle is measured as the pointer moves along a graduated scale. In the case of a moving-mirror galvanometer, a mirror is attached to the coil, and illuminated with light. When the coil moves the deflection of the light is measured along a scale. The mirror galvanometer was of major use in laying the transatlantic telegraph cable between the United States and Europe in 1866. William Thomson, later known as Lord Kelvin, used it to keep track of how much electric current was coursing through the cable. Thomson also invented a "siphon recorder," which was a more sensitive galvanometer. Ink was siphoned through a thin glass tube that was attached to the coil of wire which was mounted between the poles of a horseshoe magnet. The moving tube carried the ink onto a paper tape where it traced a line. Galvanometers come in a variety of types. Ultraviolet recorders use light-sensitive paper and ultraviolet light in place of ink. A photoelectric galvanometer amplifies the signal using a photocell. The ballistic galvanometer is used to measure an electric pulse or burst. A cousin of the galvanometer is the direct current ammeter, which is a calibrated galvanometer that measures larger currents. Another cousin still is the direct-current voltmeter, which uses Ohm's Law to measure voltage. Digital display galvanometers, the best of which can measure a current as small as one hundredth billionth (10-11) of an amp, have almost entirely replaced the early analog galvanometers of yore. RECORDER DEFINITIONS http://www.omega.com/temperature/z/selectrecorder.html Hybrid recorder: A recorder that combines analog trend representation and digital measured value printing on the same chart paper, without disruption of trend printing. Servo balancing: A means of positioning the pen of a drag pen recorder. Null-balance operation has no current flow at balance, nullifying the effect of lead resistance. Conventional servo balancing recorders use contact mechanisms in the feedback loop and brushes in the servo motor. New technology allows the use of a noncontact pen positioning transducer and a brushless dc servo motor. Scanning recorder: A multi-point recorder that scans all of its inputs to obtain new measured data every set time period (usually 2 to 6 seconds). Printing for all points is often performed during each cycle of the printing mechanism. Multi-color printing: A recorder that records trend traces in more than one color to make traces easier to differentiate. Drag pen recorders use a different color for each pen (usually four pens maximum). Mulit-point recorders typically record in six colors. Linear scaling: Recording of a voltage input in terms of the engineering variable, such as temperature, that the voltage represents. Transformation is Y (variable to be recorded) = mX (slope x input signal) + b (Y intercept). Pen offset compensation: In traditional multiple input drag pen recorders, each pen can travel the full width of the recording chart. In order to do so, the pens must be physically offset from one another. This puts the different pen traces on different time lines of the chart. By placing the measured data of the front-most pen(s) into a buffer and delaying their printing, the traces can be synchronized to the same time line, thereby compensating for their offset. Accuracy: The closeness to the actual signal that the measured value or trend position takes, stated as either a percentage of full scale or percent of reading. Separate accuracy statements are typically provided for measuring and recording functions. Tag ID: A means of designating a trace or digital measured value by an alphanumeric identifier instead of a numeric identifier. Typically available with up to seven characters. Digital printing: Printing of the precise measured numerical values for the various channels, along with their channel identifiers. Digital printing usually occurs in a margin of the chart so as not to interrupt trend recording. Log report: A printout of precise measured numerical values for the various channels, along with their channel identifiers. Typically prints in full character height per print cycle. During trending, prints on demand, resuming trending automatically. When trending is not being used, prints at a preselected time interval. May also include alarm status indication.