Design Project

advertisement

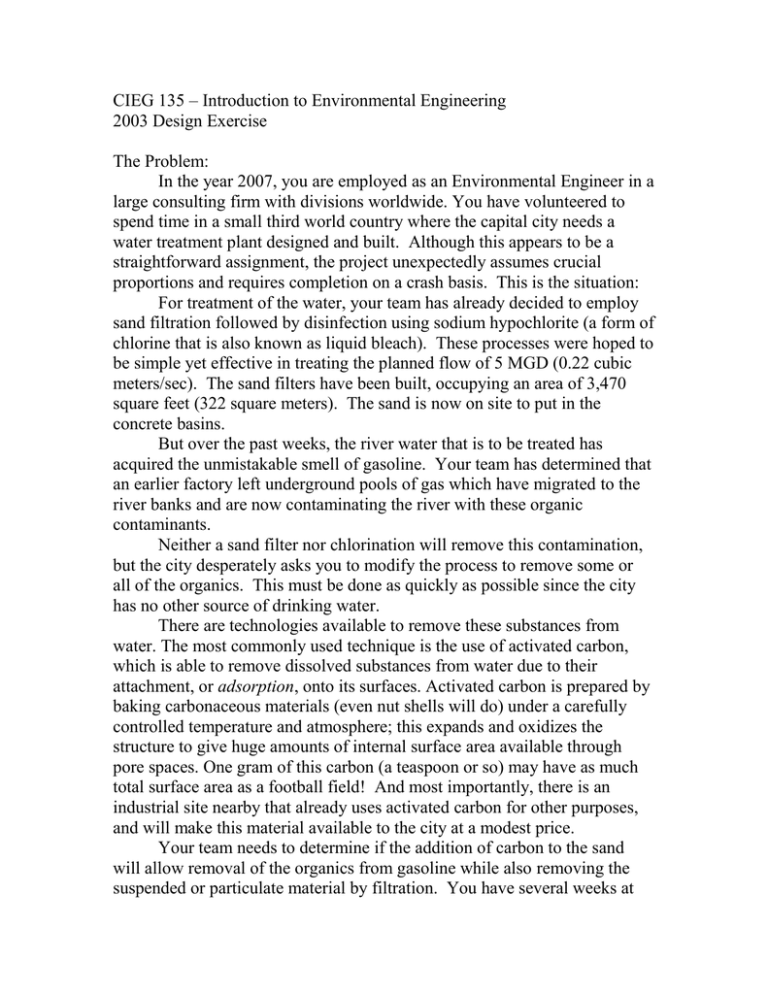

CIEG 135 – Introduction to Environmental Engineering 2003 Design Exercise The Problem: In the year 2007, you are employed as an Environmental Engineer in a large consulting firm with divisions worldwide. You have volunteered to spend time in a small third world country where the capital city needs a water treatment plant designed and built. Although this appears to be a straightforward assignment, the project unexpectedly assumes crucial proportions and requires completion on a crash basis. This is the situation: For treatment of the water, your team has already decided to employ sand filtration followed by disinfection using sodium hypochlorite (a form of chlorine that is also known as liquid bleach). These processes were hoped to be simple yet effective in treating the planned flow of 5 MGD (0.22 cubic meters/sec). The sand filters have been built, occupying an area of 3,470 square feet (322 square meters). The sand is now on site to put in the concrete basins. But over the past weeks, the river water that is to be treated has acquired the unmistakable smell of gasoline. Your team has determined that an earlier factory left underground pools of gas which have migrated to the river banks and are now contaminating the river with these organic contaminants. Neither a sand filter nor chlorination will remove this contamination, but the city desperately asks you to modify the process to remove some or all of the organics. This must be done as quickly as possible since the city has no other source of drinking water. There are technologies available to remove these substances from water. The most commonly used technique is the use of activated carbon, which is able to remove dissolved substances from water due to their attachment, or adsorption, onto its surfaces. Activated carbon is prepared by baking carbonaceous materials (even nut shells will do) under a carefully controlled temperature and atmosphere; this expands and oxidizes the structure to give huge amounts of internal surface area available through pore spaces. One gram of this carbon (a teaspoon or so) may have as much total surface area as a football field! And most importantly, there is an industrial site nearby that already uses activated carbon for other purposes, and will make this material available to the city at a modest price. Your team needs to determine if the addition of carbon to the sand will allow removal of the organics from gasoline while also removing the suspended or particulate material by filtration. You have several weeks at most to determine this. An additional pressure is that several other countries have flown in experts to assess the problem independently. Small-scale testing seems appropriate before actually filling each filter all the way to the top. However, sophisticated testing equipment is not available in the desired time span. Your team will needs to construct a simple filtration test unit and determine how best to add the carbon to the sand filter, such that the bed is able to remove any particulates in the water as well as the organic contaminants. Finally, it has been proposed that the filters treat all of the water in the river – 120 MGD. You need to determine if this would be feasible. Your team may have 2 – 3 people in it. Each team will submit a team report that should be about 5 – 10 pages (typed) in length. The report should include: 1. Overview of the problem. 2. Description of the test apparatus and procedure used. 3. The extent of removal of both the sediment and the organics contributed by the gasoline. 4. The configuration of your filter bed given the following materials: sand, rocks and carbon. 5. An explanation of why your particular configuration works. It is important to understand that there may be many ways to complete this assignment, and there is no specific “solution” that is necessarily better than all others. You will have access to an analytical balance, a spectrophotometer, or anything else that you can convince Derya that you need. Answers to important questions: Our group will not want to work with gasoline or the organics from it, since some of these are toxic substances. Can we have some sort of medical excuse from this project? Sorry. The river water that has been prepared for you has had a “surrogate” substance added to it that you can assume behaves exactly like the organics in gasoline but is perfectly safe to work with. You can assume that the concentration of organics in the water is 14 ppb. We don’t know where to get activated carbon, or other materials? If you’ve ever had an aquarium, you know that you can get activated charcoal (the same thing) at a pet supply store. And Derya has already done that for you, so each group will have carbon, sand and rocks to play with. She will also supply you with soda bottles for your “sand bed”. You may use equations for your design, but you need to figure out which ones to use. How will we be graded? The report should be clearly and attractively presented (25%), and well explained (25%). Its technical proficiency will be an important component (50%). Originality is also valued (25%): note that there may be simple ways of modifying your adsorption process to improve its performance, or clever ways to convince the local citizens that the water is again safe to drink. This is an “open – ended” assignment. I’ll get stuck in a group of slackers and end up doing all the work. That’s not a question! And at least you get to choose your own group, which may not be true in many work situations. But with regard to the grade, there are two facets. Firstly, the report will receive a grade, which will be given to all members. Engineers often work in teams and a project report reflects on all of them, regardless of whether the work was equally shared. But secondly, as your instructor for this course, I may be considered as your small firm’s CEO. I welcome you fank and open discussion of your experiences. Progress report (1 page, informal) due 11/12/03 Final report due 11/26/03