Functionalization of Surfaces with Nisin in a Poly[ethylene oxide] brush layer

advertisement

![Functionalization of Surfaces with Nisin in a Poly[ethylene oxide] brush layer](http://s2.studylib.net/store/data/015050691_1-af2ae71c944d22e8d2e8cad59c94bcc9-768x994.png)

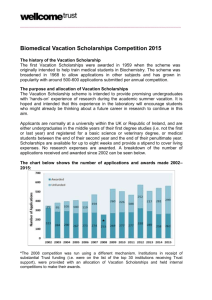

Functionalization of Surfaces with Nisin in a Poly[ethylene oxide] brush layer Matt Ryder Dr. Joe McGuire – BioEngineering OSU HHMI Summer ‘07 Hydrophobic Surface Background – Instances of Infection1 Infection in hospitals is the fourth largest killer in the US 2 million patients contract infections in hospitals each year…about 103,000 die as a result 228 infections/hour…12 deaths Cost? $30.5 billion each year Background Three issues with implanted devices Clot Formation Bacterial Adhesion Cell Proliferation Currently, methods to counteract include: Loading patients with heparin or antibiotics. Background These issues are directly related, both are initiated by adsorption events. Background – Brush Layer F108 creates brush layer that protects against protein adsorption. Protein adsorption can result in very different outcomes, from benign surface coatings, to large clot formation (therefore risk of stroke). Hydrophobic Surface Brush Layer – Protein Repellant Bare Surface F108 Coated Surface Bare Surface F108 Coated Surface A. B. Background – Nisin Nisin is a small antimicrobial peptide produced by strains of Lactococcus lactis subsp. lactis. Nisin kills Gram positive bacteria through a multistep process that destabilizes the phospholipid bilayer of the cell and creates transient pores. The efflux of low molecular weight compounds from the cytoplasm and subsequent dissipation of membrane potential rapidly kills the targeted bacterium. Nisin - Mechanism Background – Nisin & Brush Layer Goes against function of brush layer Hydrophobic Surface Hydrophobic Surface Background – Product Activity Hydrophobic Surface Hypothesis If a surface can be chemically or functionally modified to adsorb and retain the Lantibiotic Nisin, antimicrobial activity and anti clotting function will be higher as compared to current coating methods. Procedure microspheres F108 Nisin 2 days x # of days Results Optimized concentrations of F108, Nisin and microspheres in solution. Conducted serial dilution tests to find optimum concentration of Pediococcus. Researched literature for background knowledge and future effectiveness Standardized procedures to decrease variability. Obtained valuable insight on Nisin activity from longevity testing. Results 10-6 dilution w/o Nisin 10-4 dilution w/ Nisin Dilution optimized for 30-300 colonies Results 14 Colony Forming Units 12 F108-coated microspheres+nisin Uncoated microsphere+nisin 10 8 6 4 2 0 1 day 4 days Incubation time Results Colony Forming Units 200 Nisin+F108 (no microspheres) Nisin only (no microspheres) 150 100 50 0 1 day 4 days Incubation time Future Research 28 day trials with current procedure Blood serum studies to test longevity of Nisin in physiological conditions Tests with EGAP rather than F108, a more clinically accepted polymer in vitro studies using catheters Acknowledgements Special Thanks to: Dr. Joe McGuire – Mentor Dr. Christine Kelly Karle Schilke Dr. Jeff Tai – Protocols and instruction Dr. Kevin Ahern – HHMI Program The Howard Hughes Medical Institute References 1. Committee to Reduce Infectious Diseases http://www.hospitalinfection.org/essentialfacts.shtml Pictures 1. http://www.flickr.com/photos/gaspirtz/384254225/ 2. www.altham.com/html/food_hygiene_cartoons.html 3. http://www.sciencestuff.com/prod/L-p-Empty/1001-20 4. http://www.flickr.com/photos/rdbkorn/85401201/ 5. http://www.bergoiata.org/fe/favs/Bacteria.jpg 6. www.sigmaaldrich.com/img/assets/4261/micro_7.gif